Return to Section TOC

Return to Master TOC

THEORY OF OPERATION

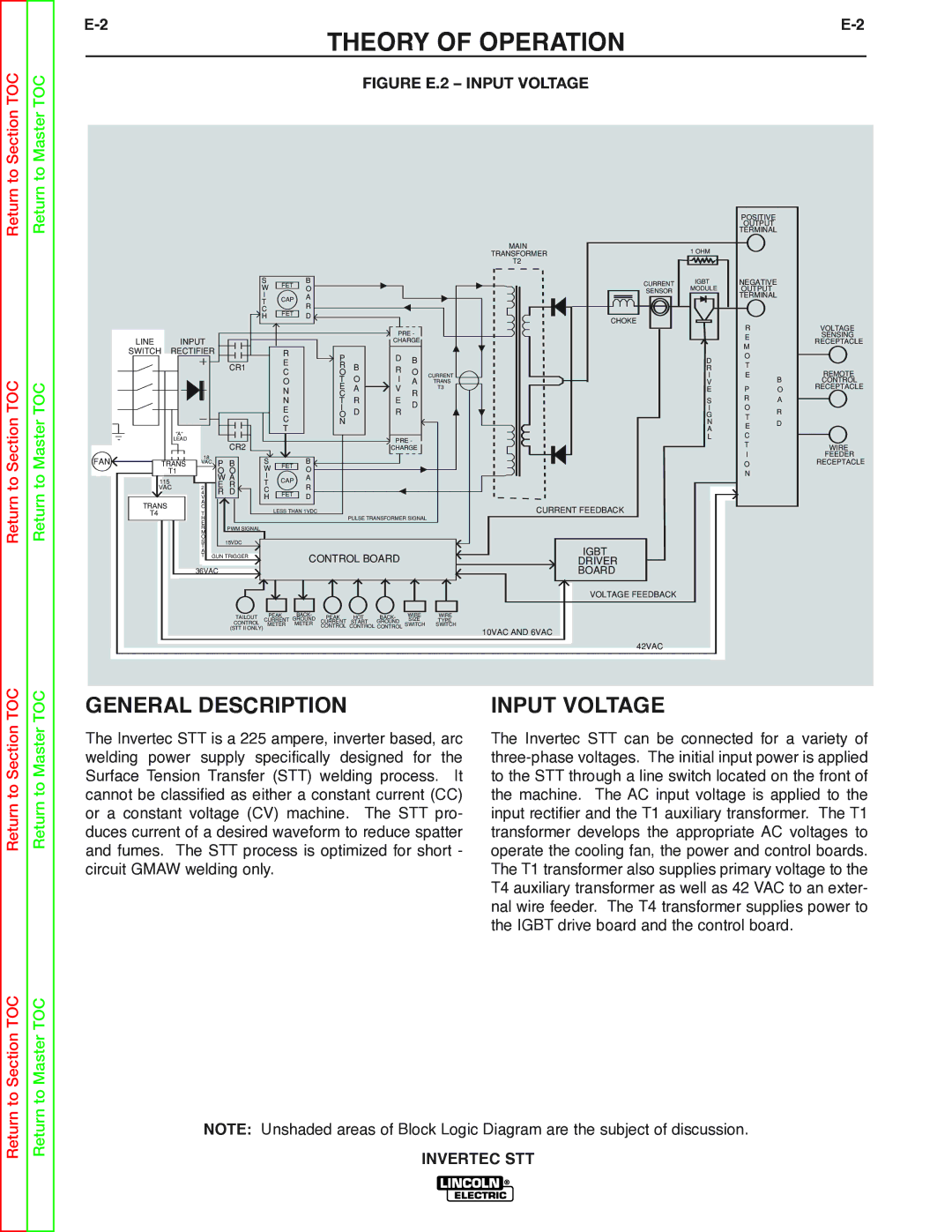

FIGURE E.2 – INPUT VOLTAGE

Return to Section TOC

Return to Master TOC

S | FET | B | |

W | O | ||

I | CAP | A | |

T | |||

R | |||

C | FET | ||

H | D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PRE - | |

|

| LINE |

| INPUT |

|

|

|

|

| CHARGE | ||||||

|

| SWITCH |

| RECTIFIER |

|

| R | P |

| D | B | |||||

|

|

|

|

|

|

|

|

|

|

|

| E |

| |||

|

|

|

|

|

|

|

|

|

| CR1 |

| R | B | R | ||

|

|

|

|

|

|

|

|

|

|

| C | O | O | |||

|

|

|

|

|

|

|

|

|

|

|

| O | T | O | I | A |

|

|

|

|

|

|

|

|

|

|

|

| N | E | A | V | R |

|

|

|

|

|

|

|

|

|

|

|

| C | ||||

|

|

|

|

|

|

|

|

|

|

|

| N | T | R | E | D |

|

|

|

|

|

|

|

|

|

|

|

| E | I | D | R | |

|

|

|

|

|

|

|

|

|

|

|

| O |

| |||

|

|

|

|

|

|

|

|

|

|

|

| C | N |

|

|

|

|

|

|

|

| "A" |

|

|

| T |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

| LEAD |

| CR2 |

|

|

|

| PRE - | ||||

FAN |

|

|

|

|

|

|

|

| 18 | S |

| B |

| CHARGE | ||

|

|

|

|

|

|

|

| P B |

|

|

|

| ||||

|

| TRANS |

| VAC | FET |

|

|

| ||||||||

|

|

|

|

|

|

|

| |||||||||

|

|

|

| T1 |

|

| O O | W |

| O |

|

|

| |||

|

|

|

|

|

|

|

|

|

| W A | I | CAP | A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| 115 |

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| E R | T | R |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

| VAC | 2 | C |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

| 4 | R D | FET |

|

|

|

| |

|

|

|

|

|

|

|

|

| V |

| H | D |

|

|

| |

|

| TRANS |

|

| A |

|

|

|

|

|

|

| ||||

|

|

|

| C |

|

| LESS THAN 1VDC |

|

|

| ||||||

|

| T4 |

|

|

|

|

| T |

|

| PULSE TRANSFORMER SIGNAL | |||||

|

|

|

|

|

|

|

|

| H |

|

|

|

| |||

|

|

|

|

|

|

|

|

| E |

|

|

|

|

|

|

|

RPWM SIGNAL

M

O

S15VDC

T

A |

|

|

T | GUN TRIGGER | CONTROL BOARD |

|

|

36VAC

TAILOUT | PEAK | BACK- | PEAK | HOT | BACK- | WIRE | |

CURRENT | GROUND | SIZE | |||||

CONTROL | CURRENT | START | GROUND | ||||

(STT II ONLY) | METER | METER | CONTROL CONTROL CONTROL | SWITCH | |||

CURRENT

TRANS

T3

WIRE

TYPE

SWITCH

|

| POSITIVE |

|

|

|

| OUTPUT |

|

|

|

| TERMINAL |

|

|

MAIN | 1 OHM |

|

|

|

TRANSFORMER |

|

|

| |

T2 |

|

|

|

|

CURRENT | IGBT | NEGATIVE |

|

|

SENSOR | MODULE | OUTPUT |

|

|

|

| TERMINAL |

|

|

CHOKE |

| R |

| VOLTAGE |

|

|

| ||

|

| E |

| SENSING |

|

|

| RECEPTACLE | |

|

| M |

| |

|

|

|

| |

| D | O |

|

|

| T |

|

| |

| R |

| REMOTE | |

| I | E | B | |

| V |

| CONTROL | |

|

|

| RECEPTACLE | |

| E | P | O | |

| S | R | A |

|

| I | O | R |

|

| G | T |

| |

| N | D |

| |

| E |

| ||

| A |

|

| |

| L | C |

|

|

|

| T |

| WIRE |

|

| I |

| FEEDER |

|

| O |

| RECEPTACLE |

|

| N |

|

|

CURRENT FEEDBACK

IGBT

DRIVER

BOARD

VOLTAGE FEEDBACK

10VAC AND 6VAC

42VAC

Return to Section TOC

Return to Master TOC

GENERAL DESCRIPTION

The Invertec STT is a 225 ampere, inverter based, arc welding power supply specifically designed for the Surface Tension Transfer (STT) welding process. It cannot be classified as either a constant current (CC) or a constant voltage (CV) machine. The STT pro- duces current of a desired waveform to reduce spatter and fumes. The STT process is optimized for short - circuit GMAW welding only.

INPUT VOLTAGE

The Invertec STT can be connected for a variety of

Return to Section TOC

Return to Master TOC

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.