Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| ||||

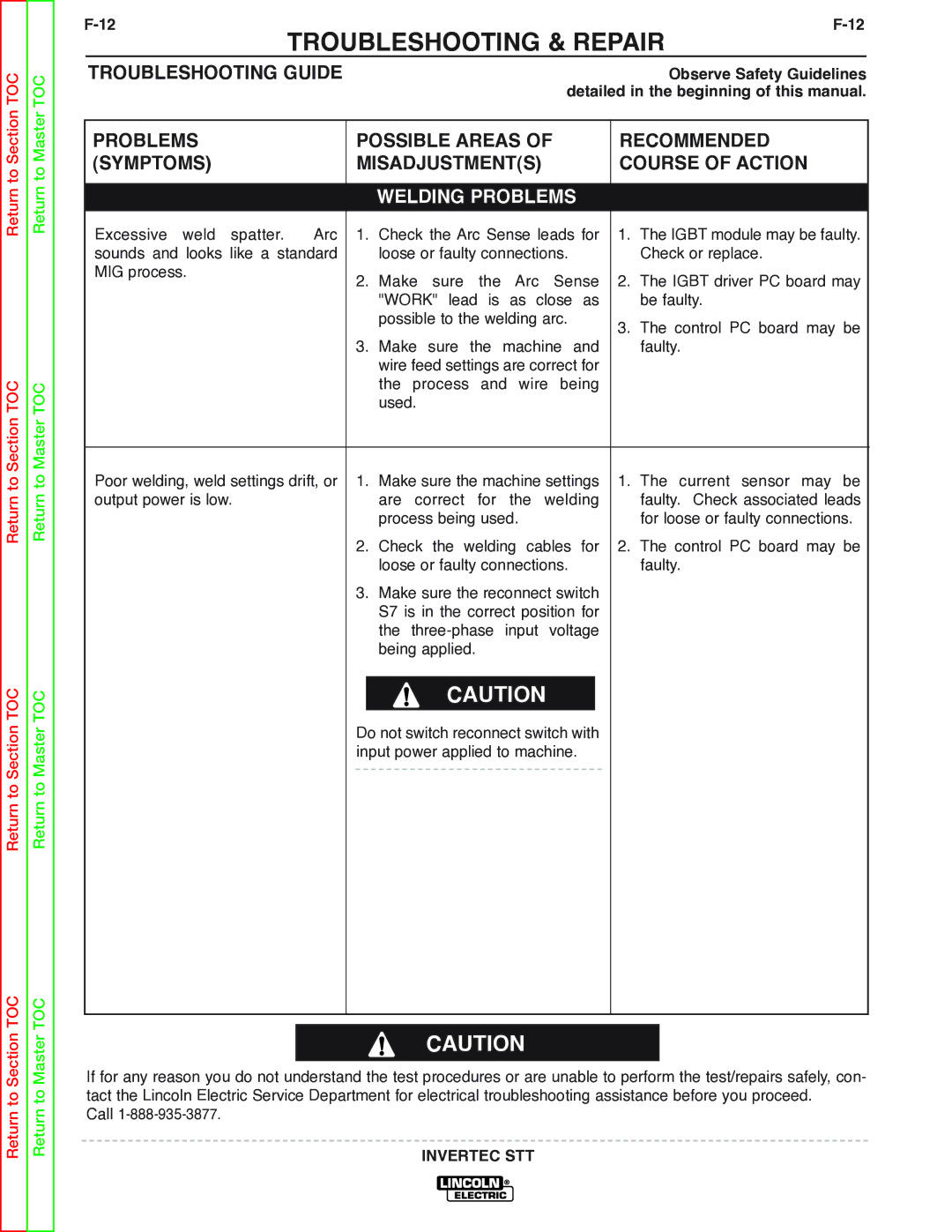

| TROUBLESHOOTING & REPAIR |

| ||

| TROUBLESHOOTING GUIDE |

| Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | ||

|

|

|

| |

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |

|

|

|

|

|

|

| WELDING PROBLEMS |

|

|

| Excessive weld spatter. Arc | 1. Check the Arc Sense leads for | 1. The IGBT module may be faulty. | |

| sounds and looks like a standard | loose or faulty connections. | Check or replace. | |

| MIG process. | 2. Make sure the Arc Sense | 2. The IGBT driver PC board may | |

|

| |||

|

| "WORK" lead is as close as | be faulty. | |

|

| possible to the welding arc. | 3. The control PC board may be | |

|

|

| ||

|

| 3. Make sure the machine and | faulty. | |

|

| wire feed settings are correct for |

|

|

|

| the process and wire being |

|

|

|

| used. |

|

|

Poor welding, weld settings drift, or 1. | Make sure the machine settings | 1. | The current sensor may be |

output power is low. | are correct for the welding |

| faulty. Check associated leads |

| process being used. |

| for loose or faulty connections. |

2. | Check the welding cables for | 2. | The control PC board may be |

| loose or faulty connections. |

| faulty. |

3. | Make sure the reconnect switch |

|

|

| S7 is in the correct position for |

|

|

| the |

|

|

| being applied. |

|

|

CAUTION

Do not switch reconnect switch with input power applied to machine.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed.

Call