5.3Printhead Adjustments

5.3.1Burn Line Adjustment

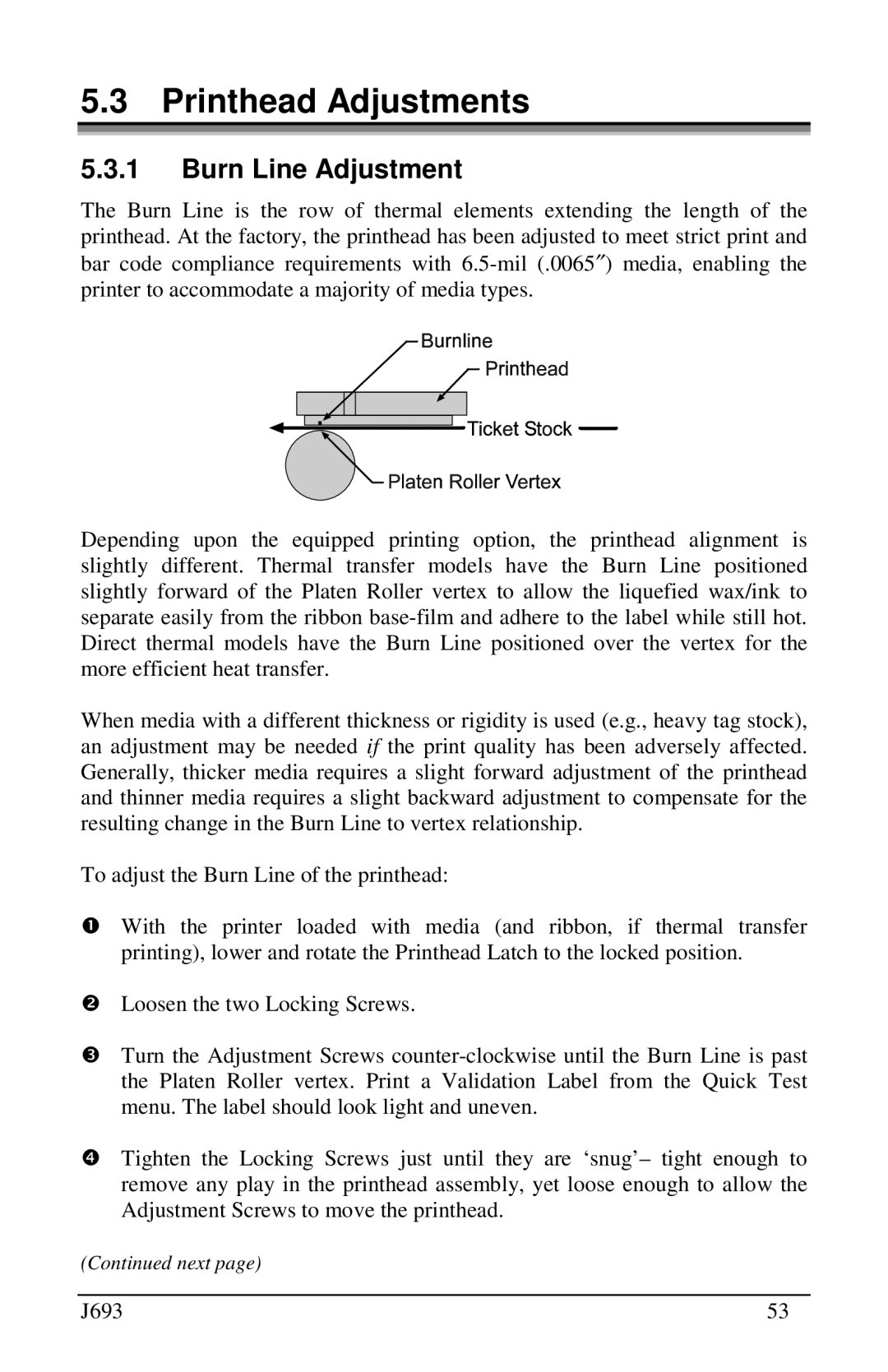

The Burn Line is the row of thermal elements extending the length of the printhead. At the factory, the printhead has been adjusted to meet strict print and bar code compliance requirements with

Depending upon the equipped printing option, the printhead alignment is slightly different. Thermal transfer models have the Burn Line positioned slightly forward of the Platen Roller vertex to allow the liquefied wax/ink to separate easily from the ribbon

anWhen media with a different thickness or rigidity is used (e.g., heavy tag stock), adjustment may be needed if the print quality has been adversely affected.

ToGenerally, thicker media requires a slight forward adjustment of the printhead a d thinner media requires a slight backward adjustment to compensate for the resulting change in the Burn Line to vertex relationship.

adjust the Burn Line of the printhead:

With the printer loaded with media (and ribbon, if thermal transfer printing), lower and rotate the Printhead Latch to the locked position.

pLoosen the two Locking Screws.

Turn the Adjustment Screws

qmenu. The label should look light and uneven.

Tighten the Locking Screws just until they are ‘snug’– tight enough to remove any play in the printhead assembly, yet loose enough to allow the Adjustment Screws to move the printhead.

(Continued next page)

J693 | 53 |