12. HANDLE MECHANISM

Before starting to work, ensure that the Power SW is OFF. Failure to observe this can cause electric shock or short circuit.

Use care so as not to damage wirings. Damaged wiring can cause electric shock or short circuit.

Do not touch undesignated places. Touching places not designated can cause electric shock or short circuit.

This work should be performed by the Location's Maintenance Man or Serviceman. Performing work by

Do not insert hand into the mechanism so as not to cause hand and fingers pinched in. Failure to observe this can cause a serious injury such as a fracture.

When performing work such as parts replacement other than those specified in this manual, be sure to contact where you purchased the product from and confirm the work procedures and obtain precautions prior to performing work. Inappropriate parts replacement and/or installing with erroneous adjustment can cause an overload or the parts to come into contact, resulting in an electric shock, a short circuit, and a fire.

Be careful when handling the plastic made parts. Failure to observe this may cause injury due to damage or fragments resulting from damage.

In the Test mode, if the variations in Volume (V. R.) values of the Handle Bar, etc. can not be set within the allowable range, Volume installation position (gear mesh) adjustment or Volume replacement is needed. Once every 3 months, be sure to apply greasing to gear mesh and spring portions.

12 - 1 ADJUSTING AND REPLACING THE THROTTLE V.R.

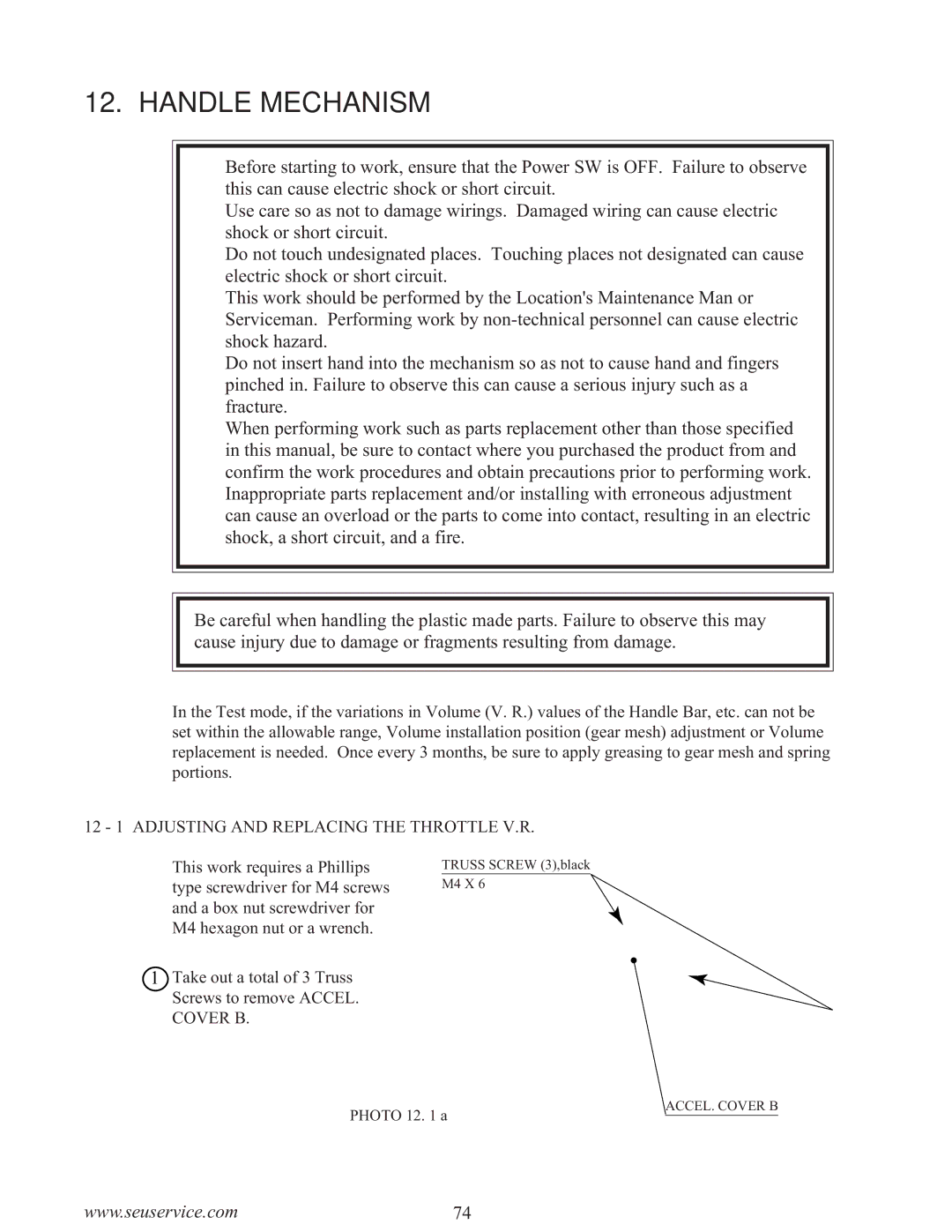

This work requires a Phillips type screwdriver for M4 screws and a box nut screwdriver for M4 hexagon nut or a wrench.

1Take out a total of 3 Truss Screws to remove ACCEL. COVER B.

TRUSS SCREW (3),black

M4 X 6

PHOTO 12. 1 a

ACCEL. COVER B

www.seuservice.com74