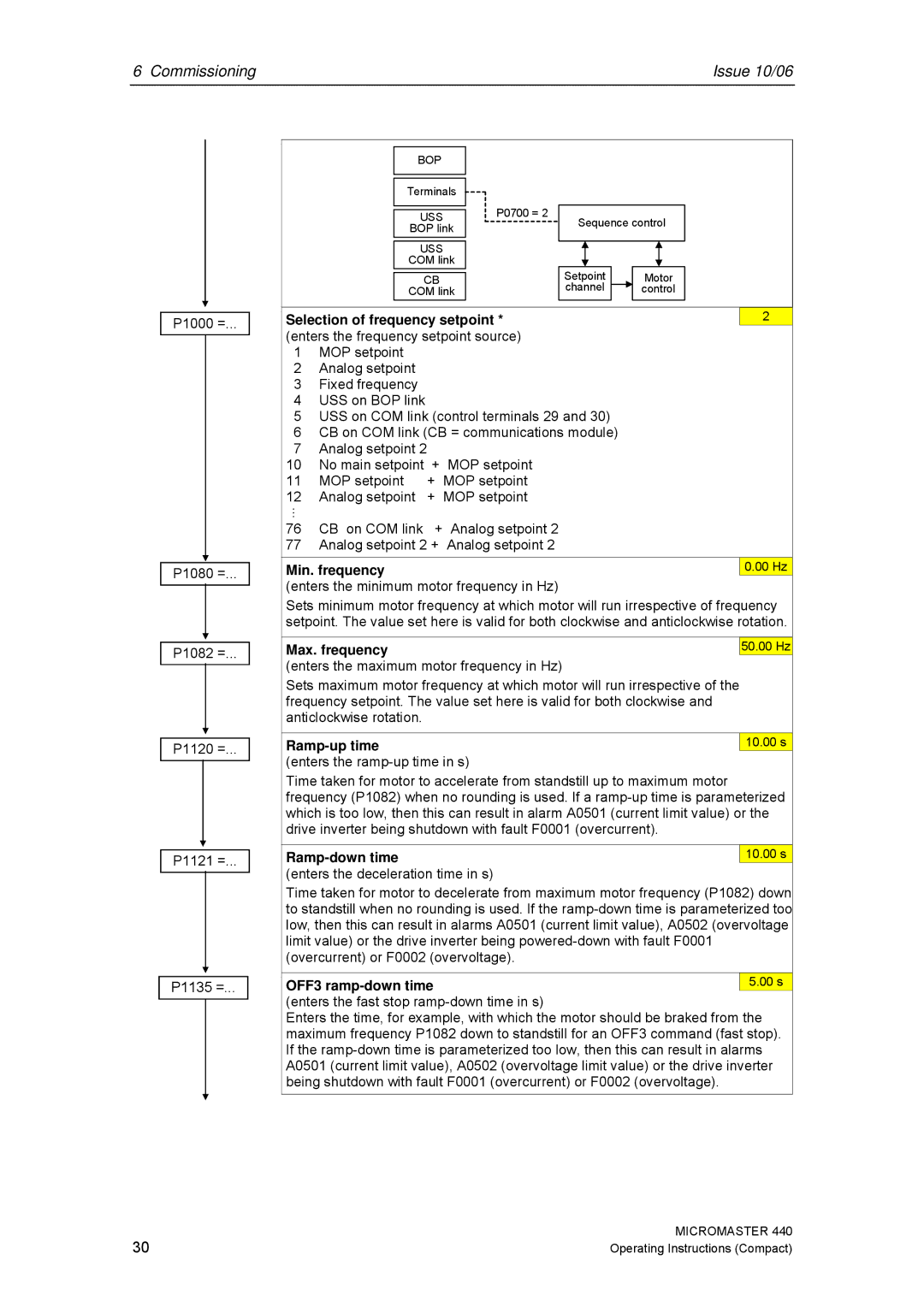

6 Commissioning | Issue 10/06 |

BOP

Terminals

USS

BOP link

USS

COM link

CB

COM link

P0700 = 2

Sequence control

Setpoint Motor

channel control

P1000 =...

P1080 =...

P1082 =...

P1120 =...

P1121 =...

P1135 =...

Selection of frequency setpoint * | 2 |

(enters the frequency setpoint source)

1MOP setpoint

2Analog setpoint

3Fixed frequency

4USS on BOP link

5USS on COM link (control terminals 29 and 30)

6CB on COM link (CB = communications module)

7Analog setpoint 2

10 No main setpoint + MOP setpoint

11 MOP setpoint + MOP setpoint

12 Analog setpoint + MOP setpoint

... |

|

|

|

76 | CB on COM link | + Analog setpoint 2 | |

77 | Analog setpoint 2 + Analog setpoint 2 | ||

|

|

| |

Min. frequency |

| 0.00 Hz | |

(enters the minimum motor frequency in Hz)

Sets minimum motor frequency at which motor will run irrespective of frequency setpoint. The value set here is valid for both clockwise and anticlockwise rotation.

Max. frequency | 50.00 Hz |

(enters the maximum motor frequency in Hz)

Sets maximum motor frequency at which motor will run irrespective of the frequency setpoint. The value set here is valid for both clockwise and anticlockwise rotation.

| 10.00 s |

(enters the

Time taken for motor to accelerate from standstill up to maximum motor frequency (P1082) when no rounding is used. If a

| 10.00 s |

(enters the deceleration time in s)

Time taken for motor to decelerate from maximum motor frequency (P1082) down to standstill when no rounding is used. If the

OFF3 | 5.00 s |

(enters the fast stop

Enters the time, for example, with which the motor should be braked from the maximum frequency P1082 down to standstill for an OFF3 command (fast stop). If the

30 | MICROMASTER 440 |

Operating Instructions (Compact) |