Issue 10/06 | 6 Commissioning |

6.4.18.8Load torque monitoring

P2181 = ...

P2182 = ...

P2183 = ...

P2184 = ...

P2185 = ...

P2186 = ...

P2187 = ...

P2188 = ...

P2189 = ...

P2190 = ...

P2192 = ...

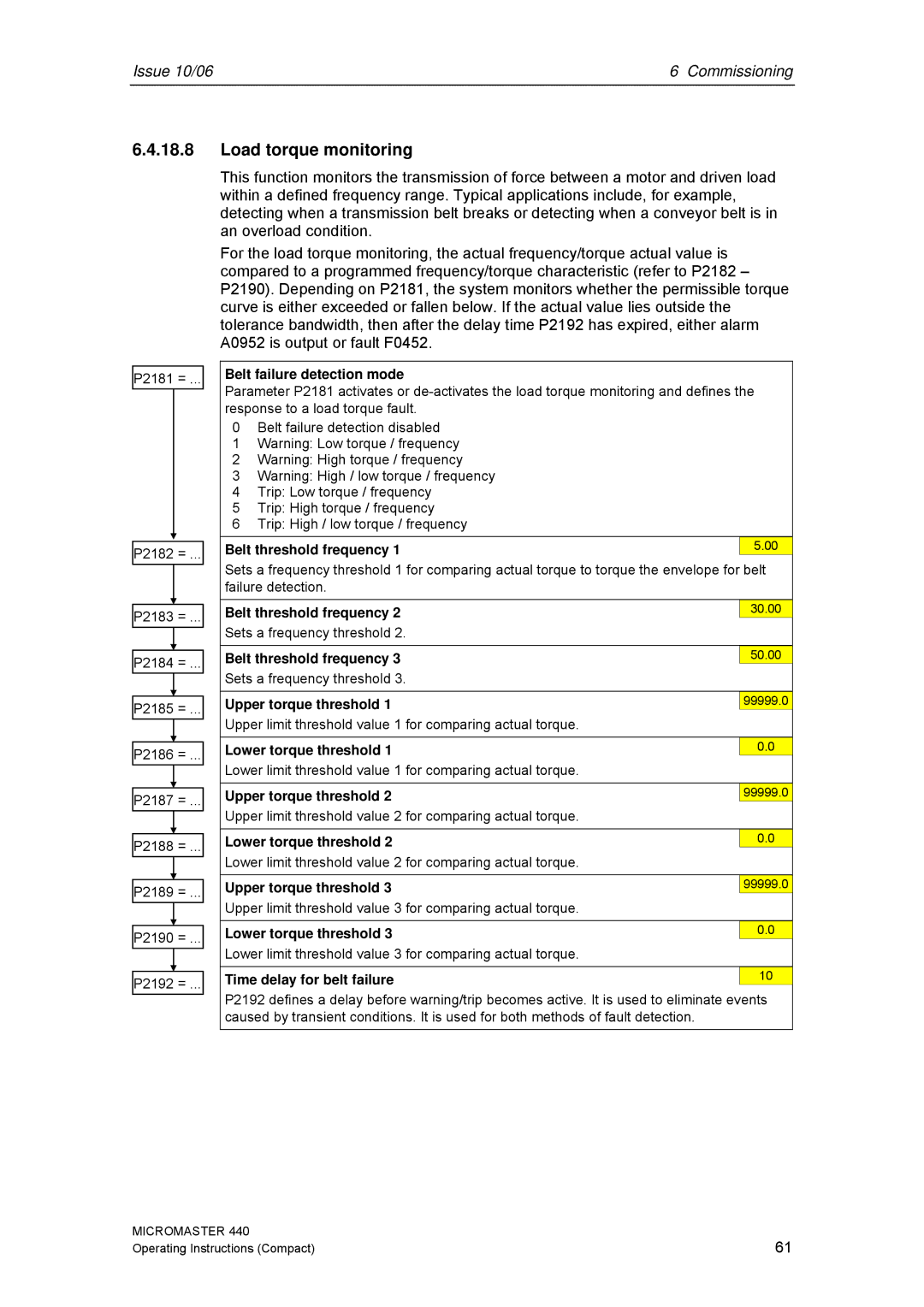

This function monitors the transmission of force between a motor and driven load within a defined frequency range. Typical applications include, for example, detecting when a transmission belt breaks or detecting when a conveyor belt is in an overload condition.

For the load torque monitoring, the actual frequency/torque actual value is compared to a programmed frequency/torque characteristic (refer to P2182 – P2190). Depending on P2181, the system monitors whether the permissible torque curve is either exceeded or fallen below. If the actual value lies outside the tolerance bandwidth, then after the delay time P2192 has expired, either alarm A0952 is output or fault F0452.

Belt failure detection mode

Parameter P2181 activates or

0Belt failure detection disabled

1Warning: Low torque / frequency

2Warning: High torque / frequency

3Warning: High / low torque / frequency

4Trip: Low torque / frequency

5Trip: High torque / frequency

6Trip: High / low torque / frequency

Belt threshold frequency 1 | 5.00 |

Sets a frequency threshold 1 for comparing actual torque to torque the envelope for belt failure detection.

Belt threshold frequency 2 | 30.00 |

Sets a frequency threshold 2. |

|

|

|

Belt threshold frequency 3 | 50.00 |

Sets a frequency threshold 3. |

|

|

|

Upper torque threshold 1 | 99999.0 |

Upper limit threshold value 1 for comparing actual torque. |

|

|

|

Lower torque threshold 1 | 0.0 |

Lower limit threshold value 1 for comparing actual torque. |

|

|

|

Upper torque threshold 2 | 99999.0 |

Upper limit threshold value 2 for comparing actual torque. |

|

|

|

Lower torque threshold 2 | 0.0 |

Lower limit threshold value 2 for comparing actual torque. |

|

|

|

Upper torque threshold 3 | 99999.0 |

Upper limit threshold value 3 for comparing actual torque. |

|

|

|

Lower torque threshold 3 | 0.0 |

Lower limit threshold value 3 for comparing actual torque. |

|

|

|

Time delay for belt failure | 10 |

P2192 defines a delay before warning/trip becomes active. It is used to eliminate events caused by transient conditions. It is used for both methods of fault detection.

MICROMASTER 440 | 61 |

Operating Instructions (Compact) |