7SA511 Numerical Line Protection Relay

Page

Table of Contents

July 27

List of Figures

Table of Contents

This page intentionally blank

Using This Manual

If you want to

Then read

Abbreviations and Acronyms

Glossary of Terms and Abbreviations

Terms

Stage

Pickup

Reclaim time

Reverse

Line Protection Relay 7SA511

Ground fault detection input

This page intentionally blank

Product Description

7SA511 Line Protection Relay Product Description

About the Relay

Relay Setting Types

Relay Features

Description

Relay Setting Descriptions by Address Block

Address

LCD Text

4000

Annunciations Operational Annunciations Last Fault

Distance Protection

Feature

Fault detection options

Overview of Protection Functions

Feature

Power Swing Protection optional

Emergency Overcurrent Protection

Pilot Protection

High-Resistance Ground Fault Protection optional

Automatic Reclose optional

Distance-to-Fault Location

Front Panel Port

Additional Functions and Features of the Relay

Secured Data Storage

Serial Data Ports

Multiple Parameter Sets optional

Acceptance Tests

7SA511 Line Protection Relay Acceptance Tests

IEC Ansi

Test Equipment

Rated Voltage

Inrush peak

Reading the Initial Display

Energizing the Relay

Or Direkteadresse

Verifying the Language Setting

If the display shows Then

Relay Settings for Acceptance Tests

Power Supply Test

Power Consumption Test

Relay Terminal Connections Test Equipment Relay

Alarm Relay Contact Test

Current Input Connections Addr. No

Metering Tests

Current and Frequency Metering Test

Model No

Voltage Metering Test

Voltage Input Connections Addr. No LCD Text

Tolerance

Input

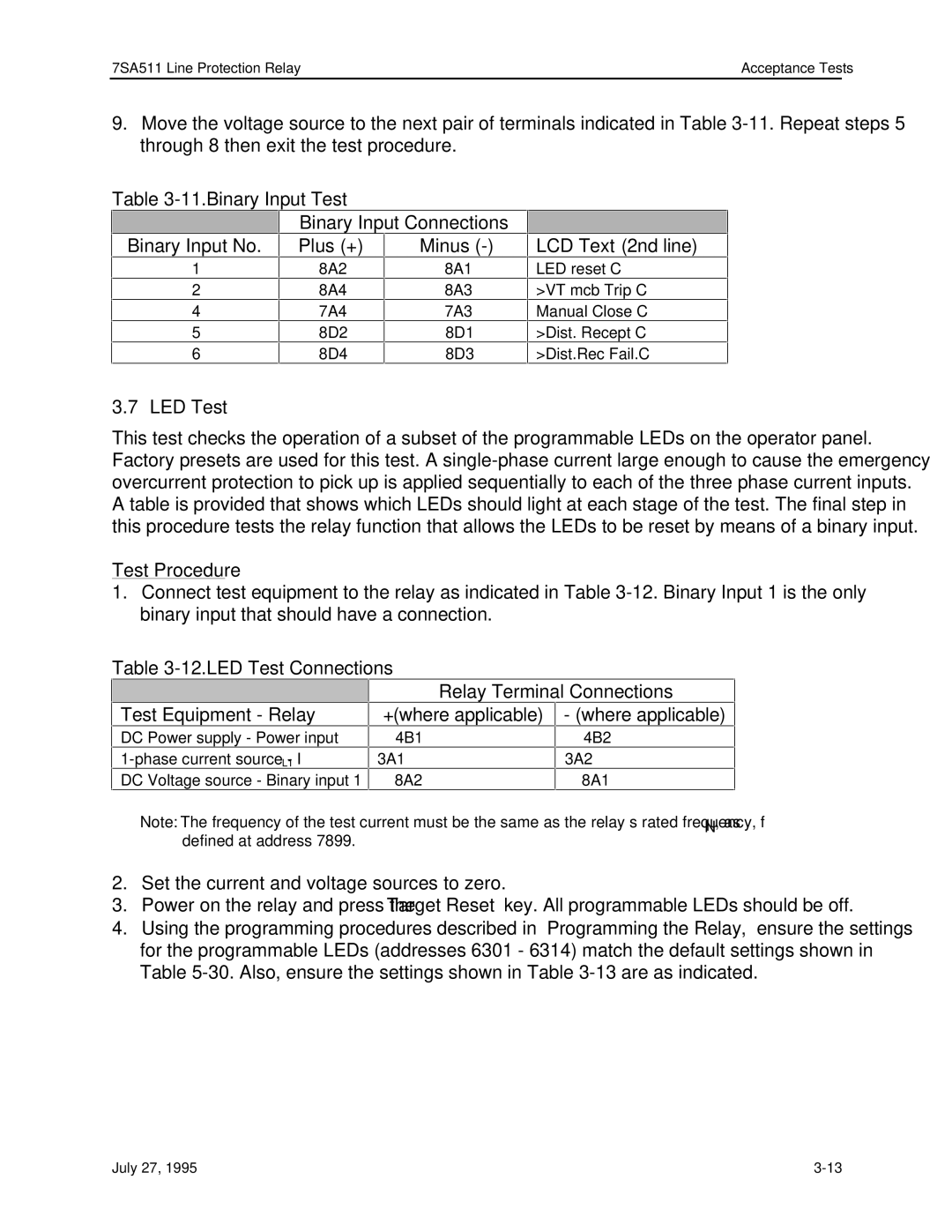

Binary Input Test

Addr

Index No

LED Test

Minus

Addr LCD Text

14. LED Test Current Input Connections

EMERG.O/C on

Signal and Trip Relay Test

Setting

Testing the Fault Detection Systems

Overcurrent Fault Detection Test

Prerequisite Settings Addr LCD Text

Voltage-Controlled Overcurrent Fault Detection Test Optional

Prerequisite Setting Addr. LCD Text

Impedance Fault Detection Test optional

Prerequisite Setting Addr LCD Text

Impedance Zone

VP/V = KRRAIP/IN

Testing the Distance Zones

Fault Type

Setting value X of the distance zone to be checked

Independent Zones Z1, Z2, and Z3

Zone Test Type

Overreach Zones Z1B and Z1L

Testing the Power Swing Blocking Function Optional

Power Swing Exist PROGR. OUT-OF-STEP Trip

Coordination Times

Permissive Underreach Transfer Trip Putt

Signal Transmission Test

Addr Setting Option Description

Test

Permissive Overreach Transfer Trip Pott

Setting at Address

Putt Mode Action Zone Expected Result

Pott Mode

Revers Interlock

Emergency Overcurrent Protection Test

Initial Setup

High-Set Overcurrent

DIST. PROT. NON-EXIST EMERG. O/C Exist

Definite Time Ov rcurrent Protection

Overcu rent T Procedure

Definite Time

High-Set

Input/Output Units

FNo

Inverse Time

Testing the Automatic Reclose AR Function Optional

End of Acceptance Testing

Prerequisite Settings Addr LCD Text Description

This page intenionally blank

Installation

7SA511 Line Protection Relay Installation

7SA511

Receiving and Handling the Relay

Storing the Relay

Preparing the Relay for Installation

Removing the Relay’s Front Cover

Removing/Installing Relay Modules

Removing the basic module

Removing the additional I/O module

Inserting the additional I/O module

Inserting the basic module

Printed Circuit Board Locations

Changing the Binary Input Voltage Range

Installing the Backup Battery

Battery Installation Procedure

View a

View a

Mounting the Relay

General Connection Drawings

Connecting the Relay to Your System

Line-NeutralVL2 Voltage Inputs

Wire Port

#8 Ring lugs #10 Ring lugs

Voltage, Signal & Tripping Terminal Block

B a

14. VT Circuits

Phase CTs with residual connection For ground faults

T. connection with broken-delta for optimum

Pilot Wire Connection Diagrams

StationB

Station

This page intentionally blank

Programming the Relay

7SA511 Relay’s Operator Panel

Operator Panel

Introduction

7SA511

Keypad

LEDs

On/Off switch

Display Panel

Nameplate

General Procedures for Programming the Relay

Reserved Area for LED Labels

Front Serial Data Port

KeyFunction

Key

Using the Navigation Keys

Placing the Relay in Programming Mode

Selecting an Dress

You wa to choose is displayed on the LCD

Changing a S tting

Saving New Settings

Step Action Result By use of the key

Enabling the Relay for Substation Control Optional

Options/Range

Preset

Waveform Capture Settings

Addr LCD Text Description

Fault detection pickup Trip command

Baud

If address 2802 setting is

Relay Scope of Functions

Operating Parameters

Operating Settings

Options

Section

English

Language OPER. Baud Date Format Fault Indic

DD.MM.YYYY By Fault Detec

MM/DD/YYYY By Trip Command

Difference Time

Real-Time Clock

Date

Set Time

Parameter Changeover Optional

Synchronizing the Clock

PARAM.C/O

Configuring a Parameter Set

Configuring Each Parameter in Each Set

Accesses this parameter set

Copying Parameter Sets

Selecting the Active Parameter Set

Address Copy Action

System Settings

Power System Settings

Deactivating Parameter Changeover

Settings for Measured Value Monitoring

Fuse Fail

Distance Protection Settings

Fault Loop Earthed Network Fault Loop NON-EARTHED NET

Addr. Block

Z1B Z1L

General Settings

Independent Zones Z1, Z2, Z3

Controlled Overreach Zones Z1B and Z1L

Zone & Description Preset

Overcurrent Fault Detection Settings

Prerequisite Settings Addr. LCD Text

Zone & Description

Voltage Controlled Overcurrent Fault Detection

Exist U/I

PROG. U/I

RA1 RA2 RAE

Polygonal Impedance Fault Detection

Exist Impedance Zone

PROG. ZA

Determination of the Fault Loop for Grounded Systems

Preset Options/Range

LCD Text Description

Exist Impedance Zone Exist

Power Swing Protection 2000 Optional

Phase Pref

L3L1 Acyclic

Permissive Underreach Transfer

Addr LCD Text Description Preset

OFF FD Acceleration

Putt Mode SEND-PRL REC-PROL SEND-DEL

Permissive Overreach Transfer

Z1B Acceleration

Forwards

Pott Mode Transblo Wait TB SEND-PRL

SEND-DEL Echo ECHO-DEL ECHO-IMP ECHO-BLO

Z1B Release

Stage

MAN. Close

Earthfault

Exist Compensated Isolated

CT ERR CT ERR. F1 CT ERR. F2

Directional D.T. Solidly Earthed

Directional Protection With Nondirectional Backup

DIREC. Comparison Solidly Earthed

Direct

Direction NON-DIR

Block

Normal Inverse

Description Preset

Nondirectional, Inverse Time Overcurrent Protection

Charac

Device Configuration for Automatic Reclose

Option

Internal AR

Automatic Reclose Function Settings

Addr LCD Text Description Preset Options/Range

Terminology

Prerequisite Setting Addr LCD Text Description

Fault Location Settings

Compar Echo

Turning the Relay Functions On and Off

Function

See Section

Procedure for Configuring the Logical Functions

Configuration Settings

BelowFAILU. RELAY424V

AR on no AR OFF no

Presettings

Addr Unit Index No

LCD Text 2nd line

LED

Binary Inputs

Signal Relays

LED Indicators

Trip Relays

This page intentionally blank

Displaying System and Relay Information

This page intentionally blank

Using the Operator Panel to Display Information

Event Log

Ess. ANNUNCIATIONS5000

Binary Inputs

Storage and Display Description

Event Log Messages

LCD Text 2nd line Description Possible Tag

Monitoring Functions

General

Circuit Breaker Test Function

Power Swing Function

Ground Fault Protection

Automatic Reclose Function

Target Log for All Systems 5200, 5300,

Table Status

7SA511 Line Protection Re ay Chapter

Example Sys em Fault Messages

Command. DisTrip46 23C

Target Log Messages

LCD Text 2nd line Description

Distance Protection

Automatic Reclose

Fault Location

High-Resistance Ground Fault Protection in Grounded Systems

Emergency Overcurrent Protection

Began. E/FDetection002104357 C

Circuit Breaker Operation Statistics

Isolated Ground Fault Data Log Messages

Operational Measured Values

Reading the Measured Values

As a percentage of VN Primary specified at address

Total Maximum Recording Time

Access Start End Port

Waveform Capture

Max. Rec. Time After Pickup

33..100

Commissioning the Relay

7SA511 Line Protection Relay Commissioning the Relay

Relay Commissioning Tests

Verifying the Installation and Relay Configuration

Guidelines for Commissioning the Relay

Current, Voltage, and Phase Sequence Checks

Symmetry Error

Summation Error

Directional Test Using Load Current

Phase Sequence Check

Measurement Loop

Test Procedure

July 27

Checking the Carrier Transmission System

Overreach Zone Comparison Via Pilot Wires

Overreach Revers Interlock

Teleprotec Pott Mode

Overreach Pilot Wire Comp

Reverse Interlocking

Carrier Transmission With Release Signal

Carrier Transmission With Blocking Signal

Carrier Transmission With Underreach Transfer Signal

Overreach Z1B Blocking

DIREC.COMPARISON OFF

If address 2102 setting is

CB Auxiliary Contact Control

Circuit Breaker Trip Test

4401 4402 4403 4404

AUTO-RECL

Setting Options & Descriptions

Automatic Reclose Test 4300 Optional

LCD Text & Description

TestProcedure

Returning the Relay o Op rating Status

LCD ext

This page intentionally blank

Maintenance

7SA511 Line Protection Relay Maintenance

Electrostatic Discharge Possible equipment damage

Tracing Hardware and Software Faults

Inspecting the Power Supply Fuse

Troub eshooting Tips

Replacing the Backup Battery

Erasing Stored Data

What To Do With Defective Relays

Preset Options

Storing Relays That are Taken Out of Service

Reset Counters ?

This page intentionally blank

Method of Operation

Figure A-1Hardware Structure of the 7SA511 Relay

Figure A-18. Power Swing

7SA511 Line Protection Relay

Overview of Hardware and Protection Functions

Power System Bus

Distance Protection Overview

Voltage Subsystem

Ground Fault Detection and Processing

Overcurrent Fault Detection

PHASE-PHASE

Polygonal Impedance Fault Detection Optional

Phase angle with the R intersection applicable

Voltage Controlled Overcurrent Fault Detection Optional

Resultant Annunciation Loop

Fault Detection Module Measured Ground Fault Current Voltage

− I L

Is replaced by Which gives us

Fault Loop Determination in Grounded Systems

Fault Detection Phases

3PH Faults = PH-E only

Fault Loop Determination in Ungrounded Systems Optional

2PH-E Flts = PHASE-PHASE Leading PH-E Lagging PH-E

3PH Faults = Control