MODEL 54eA | SECTION 16.0 |

| TROUBLESHOOTING |

16.2.8 Sense line open

Most Rosemount Analytical sensors use a Pt100 or a Pt1000 in a

The analyzer can be operated with the sense line open. The measurement will be less accurate because the ana- lyzer can no longer compensate for lead wire resistance. However, if the sensor is to be used at approximately constant ambient temperature, the lead wire resistance error can be eliminated by calibrating the sensor at the measurement temperature. Errors caused by changes in resistance with changes in ambient temperature cannot be eliminated. To make the error message disappear, connect the RTD sense and return terminal with a jumper.

16.2.9 Failure factory and Failure eeprom

Turn the power off, wait about 30 sec, then turn the power back on. If the error message does not clear, call the factory. In the United States, call (800)

16.3 TROUBLESHOOTING WHEN NO FAULT MESSAGE IS SHOWING - TEMPERATURE

16.3.1 Temperature measured by standard was more than 1°C different from controller.

A.Is the standard thermometer, RTD, or thermistor accurate? General purpose

B.Is the temperature element in the sensor completely submerged in the liquid?

C.Is the standard temperature sensor submerged to the correct level?

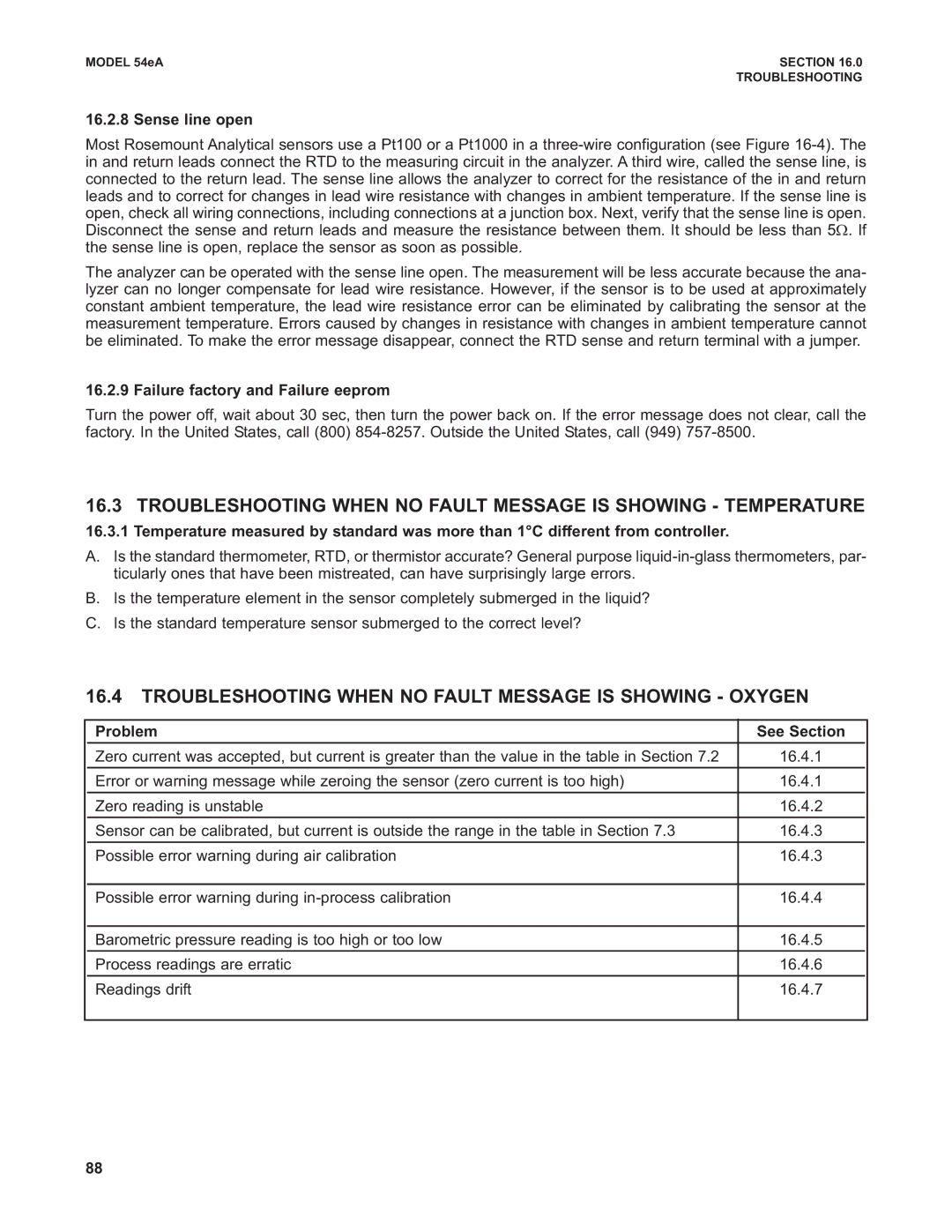

16.4TROUBLESHOOTING WHEN NO FAULT MESSAGE IS SHOWING - OXYGEN

| Problem | See Section | |

|

|

|

|

| Zero current was accepted, but current is greater than the value in the table in Section 7.2 | 16.4.1 |

|

| Error or warning message while zeroing the sensor (zero current is too high) | 16.4.1 |

|

|

|

|

|

| Zero reading is unstable | 16.4.2 |

|

|

|

|

|

| Sensor can be calibrated, but current is outside the range in the table in Section 7.3 | 16.4.3 |

|

|

|

|

|

| Possible error warning during air calibration | 16.4.3 |

|

|

|

|

|

| Possible error warning during | 16.4.4 |

|

|

|

|

|

| Barometric pressure reading is too high or too low | 16.4.5 |

|

| Process readings are erratic | 16.4.6 |

|

|

|

|

|

| Readings drift | 16.4.7 |

|

|

|

|

|

88