Standard Operations

| Table 5 Barcode program options (continued) | |

Options | Description | |

|

| |

Send Data icon / | To send data to a printer, computer or USB memory stick (Type A) | |

Send Data | ||

| ||

|

| |

| This functions as a stopwatch. It helps to ensure that the steps of an analysis are correctly timed | |

Timer icon | (e.g. reaction times, wait times, etc., can be exactly specified). When the specified time has | |

elapsed, an acoustic signal is emitted. The use of the timer has no influence on the measurement | ||

| ||

| program. | |

|

| |

| A corrective dilution factor can be entered in order to take account of certain properties. | |

| The number entered at the dilution factor prompt will be multiplied by the result to compensate for | |

Dilution Factor Off/On | the adjustment. For example, if the sample has been diluted by a factor of 2, enter 2. The default | |

setting of the dilution factor is turned off. | ||

| ||

| Note: When a dilution is in effect, the dilution icon will appear on the display. | |

| Note: If undiluted samples are used, set the dilution factor off. | |

Chemical Form | Some of the stored tests/methods allow to select the chemical form and the measuring range. | |

|

| |

Edit | To modify an existing program | |

|

| |

Save as User Program | To store the selected parameters as a User Program, see section 6.1 on page 61. | |

|

| |

Recall Data | Call up saved measurement data, wavelength scans or time courses, see section 5.3 on | |

page 35. | ||

| ||

Instrument Setup | Basic data of the instrument, see section 5.2 on page 23. | |

|

|

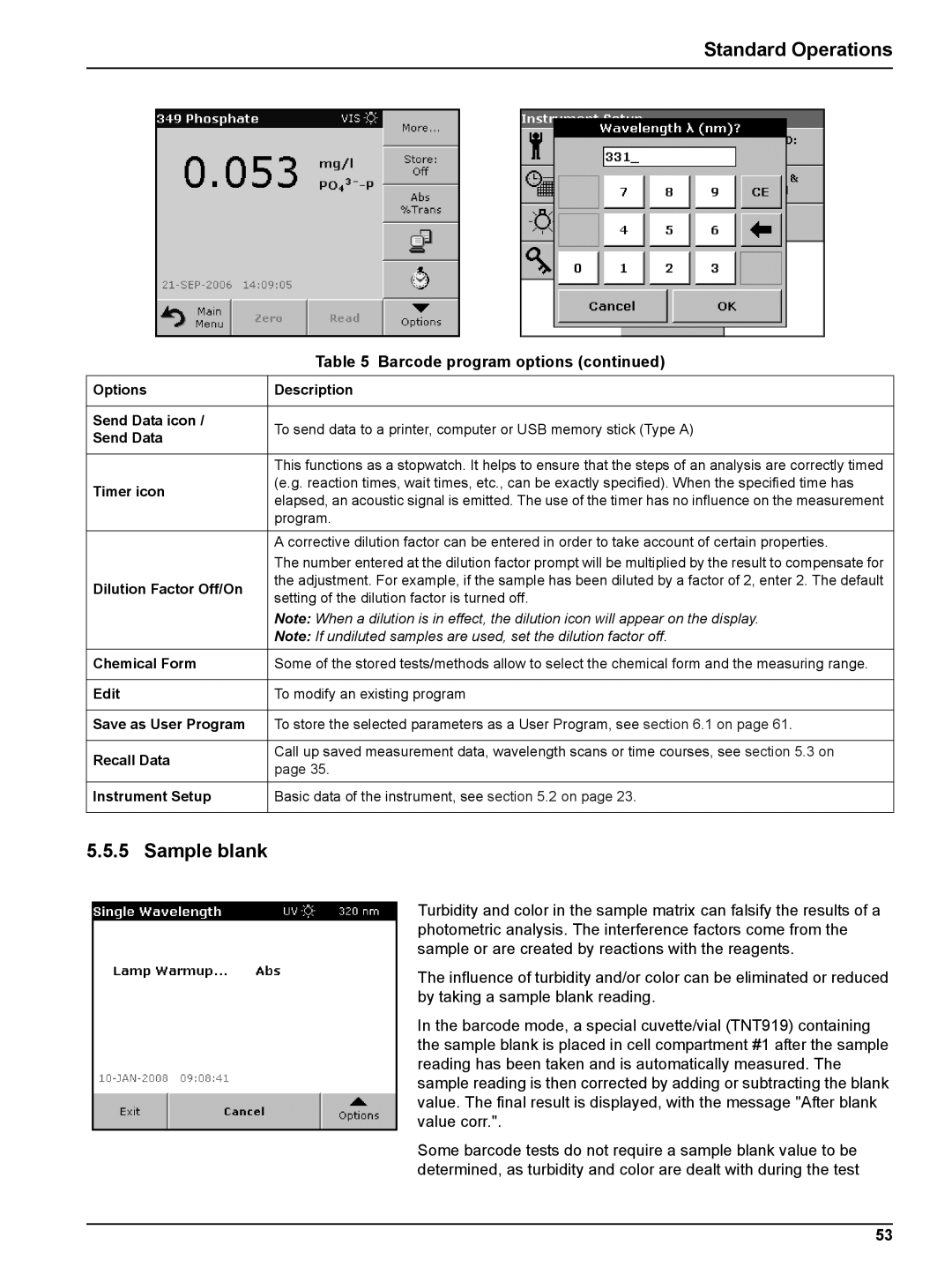

5.5.5 Sample blank

Turbidity and color in the sample matrix can falsify the results of a photometric analysis. The interference factors come from the sample or are created by reactions with the reagents.

The influence of turbidity and/or color can be eliminated or reduced by taking a sample blank reading.

In the barcode mode, a special cuvette/vial (TNT919) containing the sample blank is placed in cell compartment #1 after the sample reading has been taken and is automatically measured. The sample reading is then corrected by adding or subtracting the blank value. The final result is displayed, with the message "After blank value corr.".

Some barcode tests do not require a sample blank value to be determined, as turbidity and color are dealt with during the test

53