|

|

|

| OPERATION |

|

|

| |||||

|

|

|

|

|

|

|

|

| ||||

TOC | TOC | WELDING PERFORMANCE |

| As a general guideline for CC welding, set Arc Force to | ||||||||

Section | Master |

|

|

|

| “Mid” position and increase (typically to no more than | ||||||

LOW INDUCTANCE TERMINAL |

| #7) as necessary to prevent “stubbing” or | ||||||||||

|

| The inside right Negative | while welding. This higher arc force is recommended | |||||||||

to | to | especially for low end 6010 stick welding. | ||||||||||

inductance and presently is only recommended for |

|

|

|

|

|

| ||||||

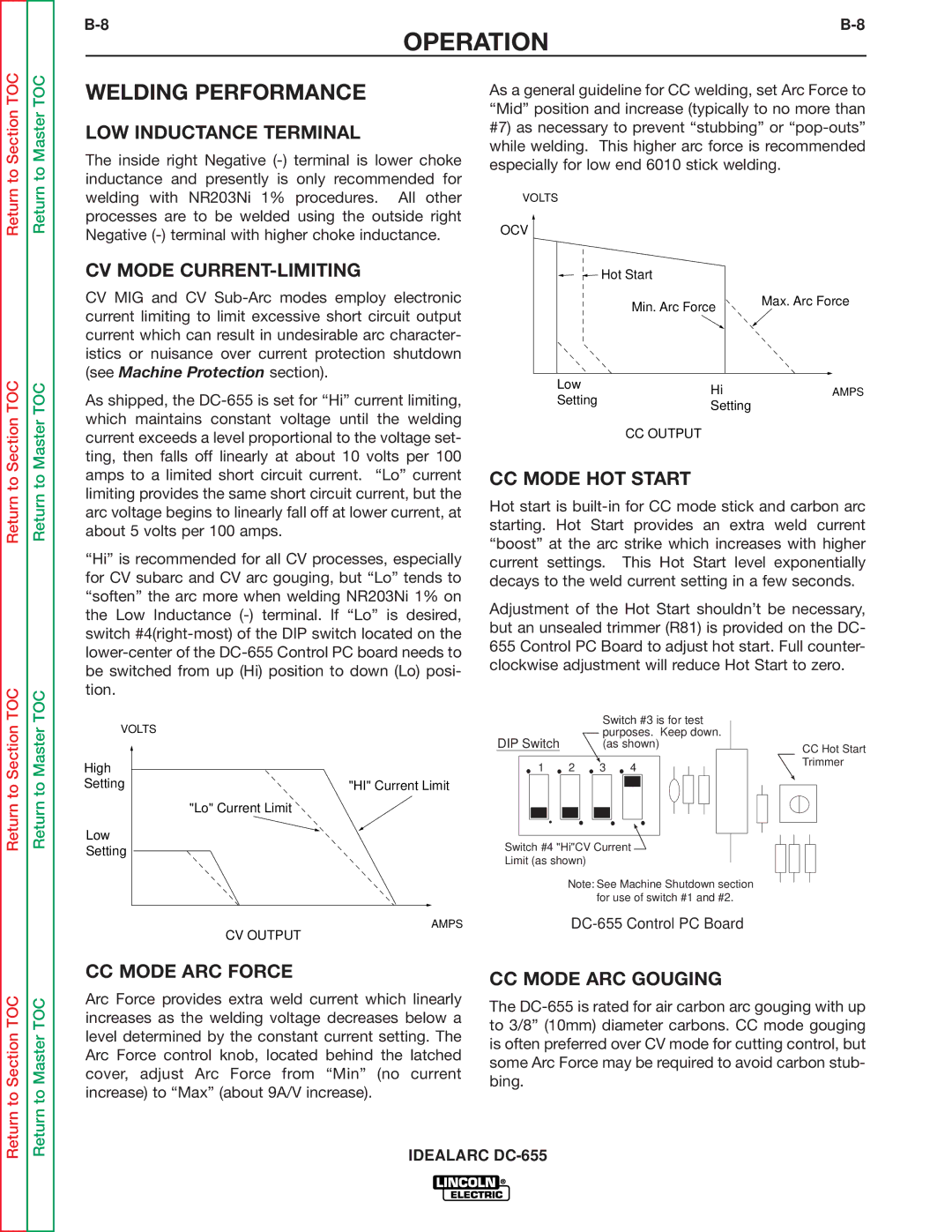

Return | Return | OCV |

|

|

|

|

| |||||

welding | with NR203Ni 1% procedures. | All other |

|

|

|

|

| |||||

|

| VOLTS |

|

|

|

| ||||||

|

| processes are to be welded using the outside right |

|

|

|

|

|

| ||||

|

| Negative |

|

|

|

|

|

| ||||

|

| CV MODE |

|

|

| Hot Start |

|

| ||||

|

| CV MIG and CV |

|

|

| Min. Arc Force | Max. Arc Force | |||||

|

| current limiting to limit excessive short circuit output |

|

|

|

|

| |||||

|

|

|

|

|

|

|

| |||||

|

| current which can result in undesirable arc character- |

|

|

|

|

|

| ||||

|

| istics or nuisance over current protection shutdown |

|

|

|

|

|

| ||||

TOC | TOC | (see Machine Protection section). |

|

| Low |

|

|

|

| |||

As shipped, the |

|

| Hi |

| AMPS | |||||||

| Setting |

| ||||||||||

|

|

|

| |||||||||

|

|

| Setting |

| ||||||||

|

| which maintains constant voltage until the welding |

|

|

|

| ||||||

Section | Master |

|

|

| CC OUTPUT |

|

| |||||

current exceeds a level proportional to the voltage set- |

|

|

|

|

| |||||||

|

|

|

|

|

|

| ||||||

|

| ting, then falls off linearly at about 10 volts per 100 |

|

|

|

|

|

| ||||

to | to | amps to a limited short circuit current. “Lo” current | CC MODE HOT START |

|

| |||||||

limiting provides the same short circuit current, but the |

|

|

|

|

|

| ||||||

Return | Return | Hot start is | ||||||||||

arc voltage begins to linearly fall off at lower current, at | ||||||||||||

|

| |||||||||||

|

| starting. Hot | Start provides an | extra | weld current | |||||||

|

| about 5 volts per 100 amps. |

| |||||||||

|

|

| “boost” at the arc strike which increases with higher | |||||||||

|

| “Hi” is recommended for all CV processes, especially | ||||||||||

|

| current | settings. | This Hot Start | level | exponentially | ||||||

|

| for CV subarc and CV arc gouging, but “Lo” tends to | decays to the weld current setting in a few seconds. | |||||||||

|

| “soften” the arc more when welding NR203Ni 1% on | Adjustment of the Hot Start shouldn’t be necessary, | |||||||||

|

| the | Low | Inductance | is desired, | |||||||

|

| but an unsealed trimmer (R81) is provided on the DC- | ||||||||||

|

| switch | ||||||||||

|

| 655 Control PC Board to adjust hot start. Full counter- | ||||||||||

|

| |||||||||||

|

| clockwise adjustment will reduce Hot Start to zero. | ||||||||||

|

| be switched from up (Hi) position to down (Lo) posi- | ||||||||||

|

|

|

|

|

|

|

| |||||

TOC | TOC | tion. |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| Switch #3 is for test |

|

| ||||

Section | Master |

| VOLTS |

|

|

|

|

| ||||

|

| DIP Switch | purposes. Keep down. |

|

| |||||||

|

|

|

|

|

| (as shown) |

| CC Hot Start | ||||

|

|

|

|

|

|

|

|

|

|

| ||

|

| High |

|

|

| 1 | 2 | 3 | 4 |

| Trimmer | |

|

|

|

|

|

|

| ||||||

to | to | Setting | "HI" Current Limit |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||

Return | Return |

|

| "Lo" Current Limit |

|

|

|

|

|

|

| |

Low |

|

|

| Switch #4 "Hi"CV Current |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| ||

|

| Setting |

|

| Limit (as shown) |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| Note: See Machine Shutdown section |

| ||||

|

|

|

|

|

|

|

| for use of switch #1 and #2. |

| |||

|

|

|

| CV OUTPUT | AMPS |

|

| |||||

|

|

|

|

|

|

|

|

|

|

| ||

|

| CC MODE ARC FORCE | CC MODE ARC GOUGING | |

|

|

| ||

TOC | TOC | Arc Force provides extra weld current which linearly | The | |

increases as the welding voltage decreases below a | ||||

to 3/8” (10mm) diameter carbons. CC mode gouging | ||||

Section | Master | level determined by the constant current setting. The | bing. | |

cover, adjust Arc Force from “Min” (no current | ||||

|

| Arc Force control knob, located behind the latched | is often preferred over CV mode for cutting control, but | |

|

| some Arc Force may be required to avoid carbon stub- | ||

|

|

| ||

Return to | Return to | increase) to “Max” (about 9A/V increase). |

| |

IDEALARC | ||||

|

| |||