Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

INPUT CONTACTOR TEST (continued)

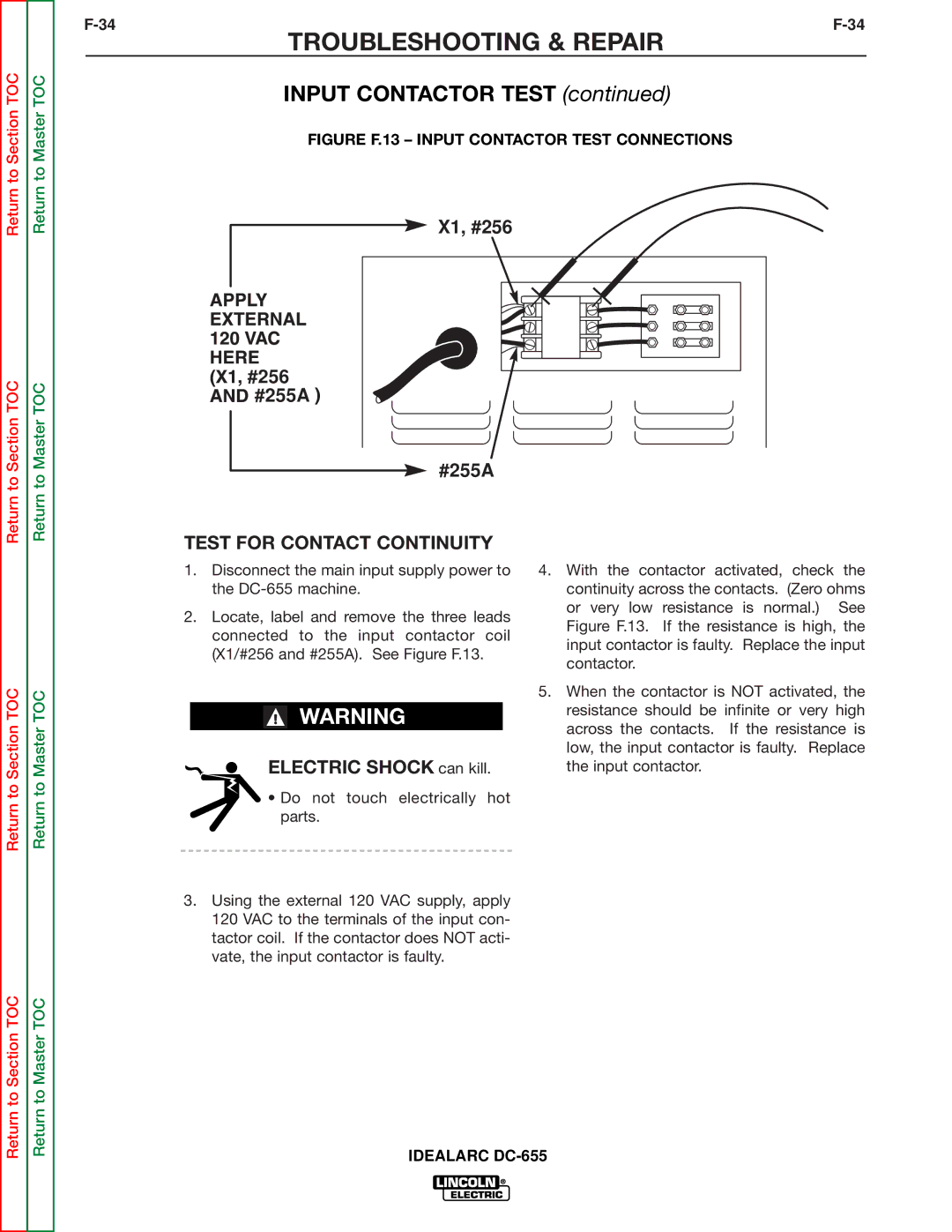

FIGURE F.13 – INPUT CONTACTOR TEST CONNECTIONS

![]() X1, #256

X1, #256

#256

![]()

![]() #255A

#255A ![]()

#255A

Return to Section TOC

Return to Master TOC

TEST FOR CONTACT CONTINUITY

1.Disconnect the main input supply power to the

2.Locate, label and remove the three leads connected to the input contactor coil (X1/#256 and #255A). See Figure F.13.

WARNING

ELECTRIC SHOCK can kill.

•Do not touch electrically hot parts.

3.Using the external 120 VAC supply, apply 120 VAC to the terminals of the input con- tactor coil. If the contactor does NOT acti- vate, the input contactor is faulty.

4.With the contactor activated, check the continuity across the contacts. (Zero ohms or very low resistance is normal.) See Figure F.13. If the resistance is high, the input contactor is faulty. Replace the input contactor.

5.When the contactor is NOT activated, the resistance should be infinite or very high across the contacts. If the resistance is low, the input contactor is faulty. Replace the input contactor.

Return to Section TOC

Return to Master TOC