Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

ACCESSORIES

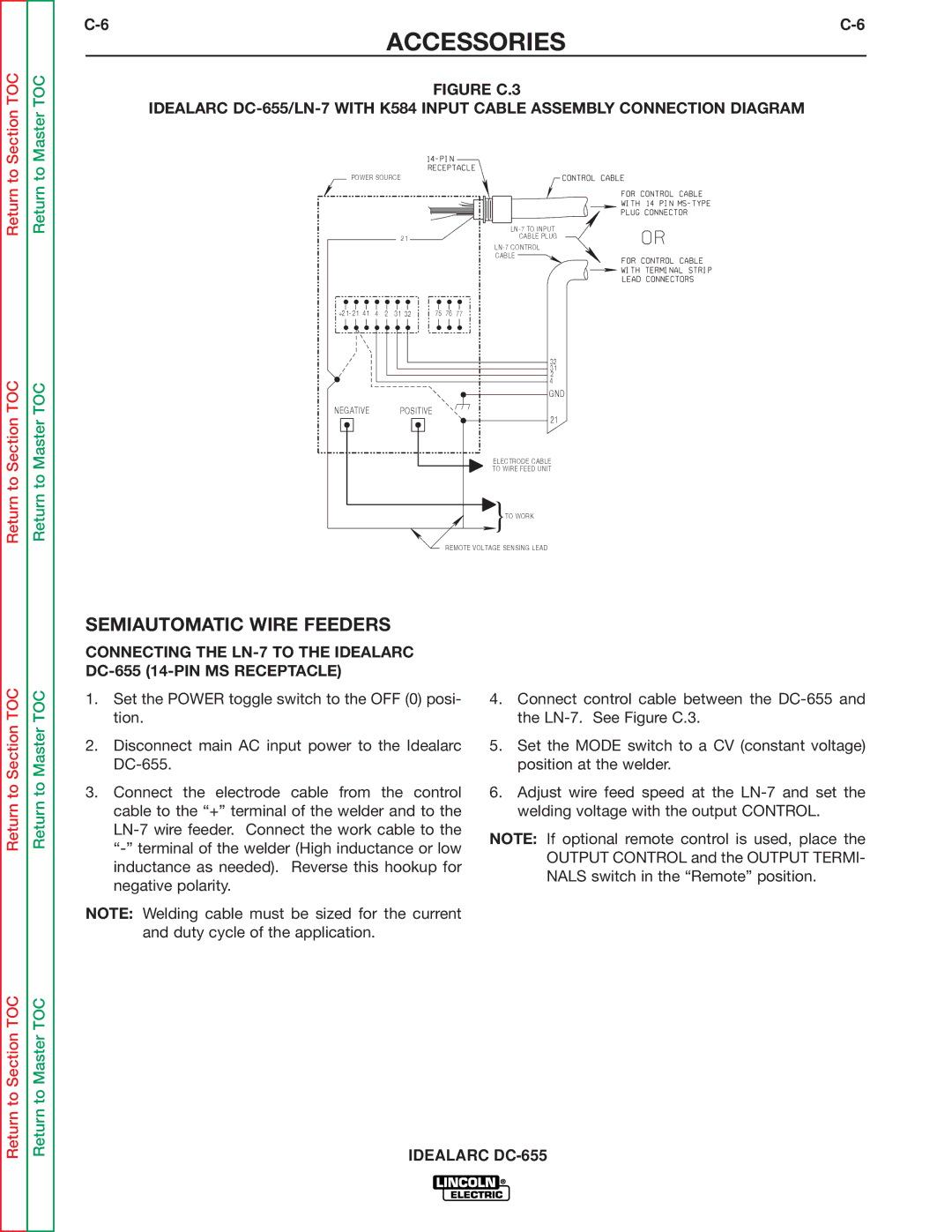

FIGURE C.3

IDEALARC DC-655/LN-7 WITH K584 INPUT CABLE ASSEMBLY CONNECTION DIAGRAM

POWER SOURCE

|

| |

21 |

| CABLE PLUG |

|

|

|

|

|

|

|

| CABLE |

+21- 21 41 | 4 | 2 | 31 32 | 75 | 76 | 77 |

|

|

|

|

|

| 32 |

|

|

|

|

|

| 31 |

|

|

|

|

|

| 2 |

|

|

|

|

|

| 4 |

|

|

|

|

|

| GND |

NEGATIVE |

|

| POSITIVE |

|

| 21 |

|

|

|

|

|

| |

|

|

|

|

|

| ELECTRODE CABLE |

|

|

|

|

|

| TO WIRE FEED UNIT |

|

|

|

|

|

| }TO WORK |

REMOTE VOLTAGE SENSING LEAD

SEMIAUTOMATIC WIRE FEEDERS

Return to Section TOC

Return to Master TOC

CONNECTING THE

1.Set the POWER toggle switch to the OFF (0) posi- tion.

2.Disconnect main AC input power to the Idealarc

3.Connect the electrode cable from the control cable to the “+” terminal of the welder and to the

NOTE: Welding cable must be sized for the current and duty cycle of the application.

4.Connect control cable between the

5.Set the MODE switch to a CV (constant voltage) position at the welder.

6.Adjust wire feed speed at the

NOTE: If optional remote control is used, place the OUTPUT CONTROL and the OUTPUT TERMI- NALS switch in the “Remote” position.

Return to Section TOC

Return to Master TOC

IDEALARC