ACCESSORIES

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

CONNECTING THE

1.Set the POWER toggle switch to the OFF (0) posi- tion.

2.Disconnect main AC input power to the Idealarc

3.Connect the electrode cable from the

Figure C.4.

NOTE: Welding cable must be sized for the current and duty cycle of the application.

4.Connect the control cable between the

5.Set the MODE switch to a CV (constant voltage) position.

6.Adjust wire feed speed at the

Place the OUTPUT CONTROL switch in the “Remote” position and the OUTPUT TERMINALS switch in the “Remote” position.

CONNECTING THE

1.Set the POWER toggle switch to the OFF (0) posi- tion.

2.Disconnect main AC input power to the Idealarc

3.Connect the electrode cable from the

NOTE: Welding cable must be sized for the current and duty cycle of the application.

4.Connect the

5.Set the MODE switch to a CV (constant voltage) position.

6.Adjust wire feed speed at the

7.Set the DIP switches on the

Place the OUTPUT CONTROL switch in the “Remote” position and the OUTPUT TERMINALS switch in the “Remote” position.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

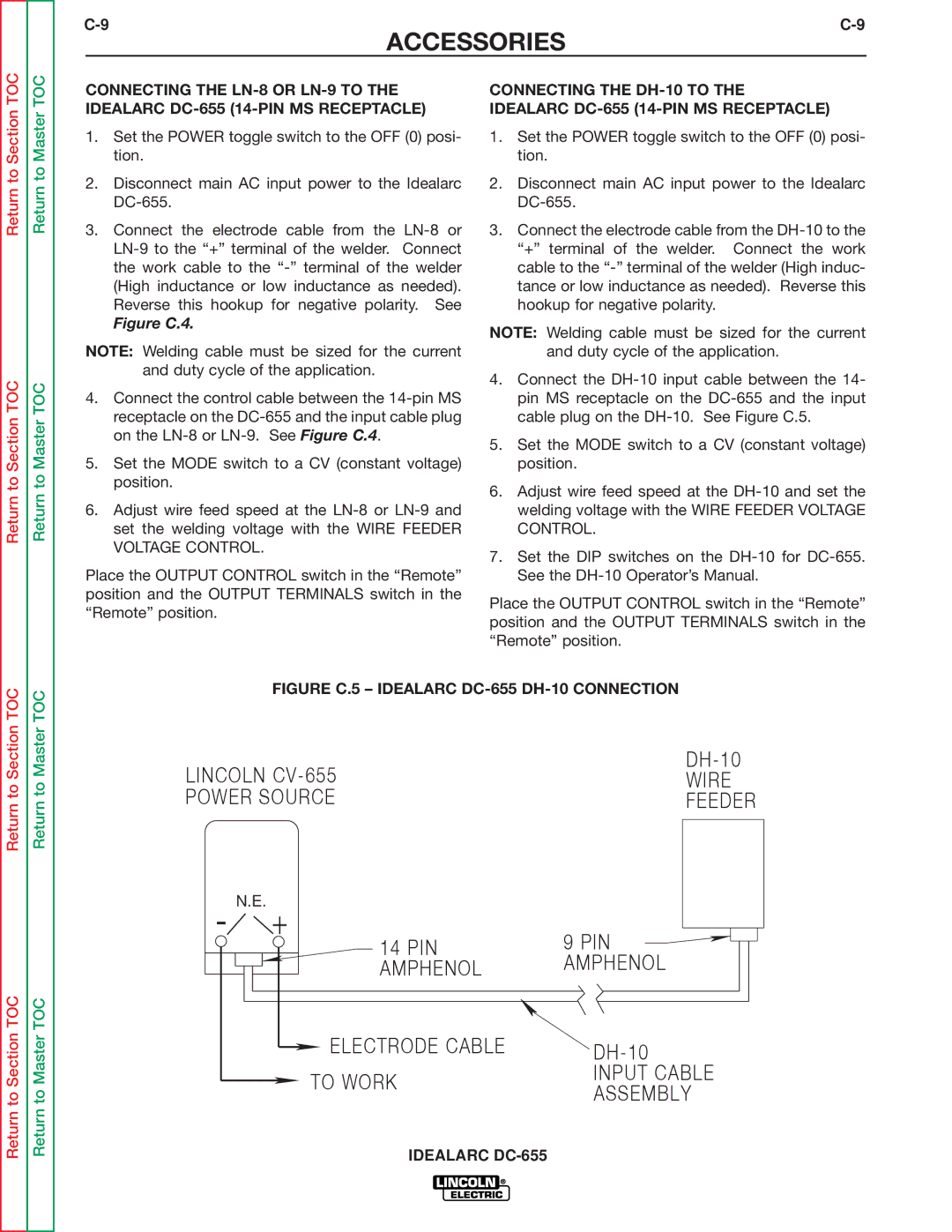

FIGURE C.5 – IDEALARC DC-655 DH-10 CONNECTION

LINCOLN | |

WIRE | |

POWER SOURCE | FEEDER |

- N.E. + | 9 PIN | |

14 PIN | ||

AMPHENOL | AMPHENOL | |

ELECTRODE CABLE | ||

TO WORK | INPUT CABLE | |

ASSEMBLY | ||

|

IDEALARC