113.197511

113.197611

Part No. SP5539

Contents

Safety

Safety Symbol and Signal Words

Major Hazards

KWARNING

Wrong Way Feed Hazard

Safety Instructions

Personal Safety Instructions

Work Area Safety Instructions

Saw Safety Instructions

Workpiece Safety Instructions

Blade Safety Instructions

On-Product Safety Labels

KWARNING

Safety

Assembly

Identify Parts

QJlIF*llfq!lt

LHllLltlLllltllllltB

Tools Needed For Assembly

Assembly Steps

Build Cabinet Base

Build Foot Assemblies

Shaped Slot

Attach Foot Assemblies

Short

Assemble Side PanelsOnly Door Model without Casters

Assembly

Attach Door Hinges

Attach/Install Spacers

Attach Side Panels to Bottom Shelf

Attach Skirts

Center Support Upper Lower

Complete Center Slide Assembly

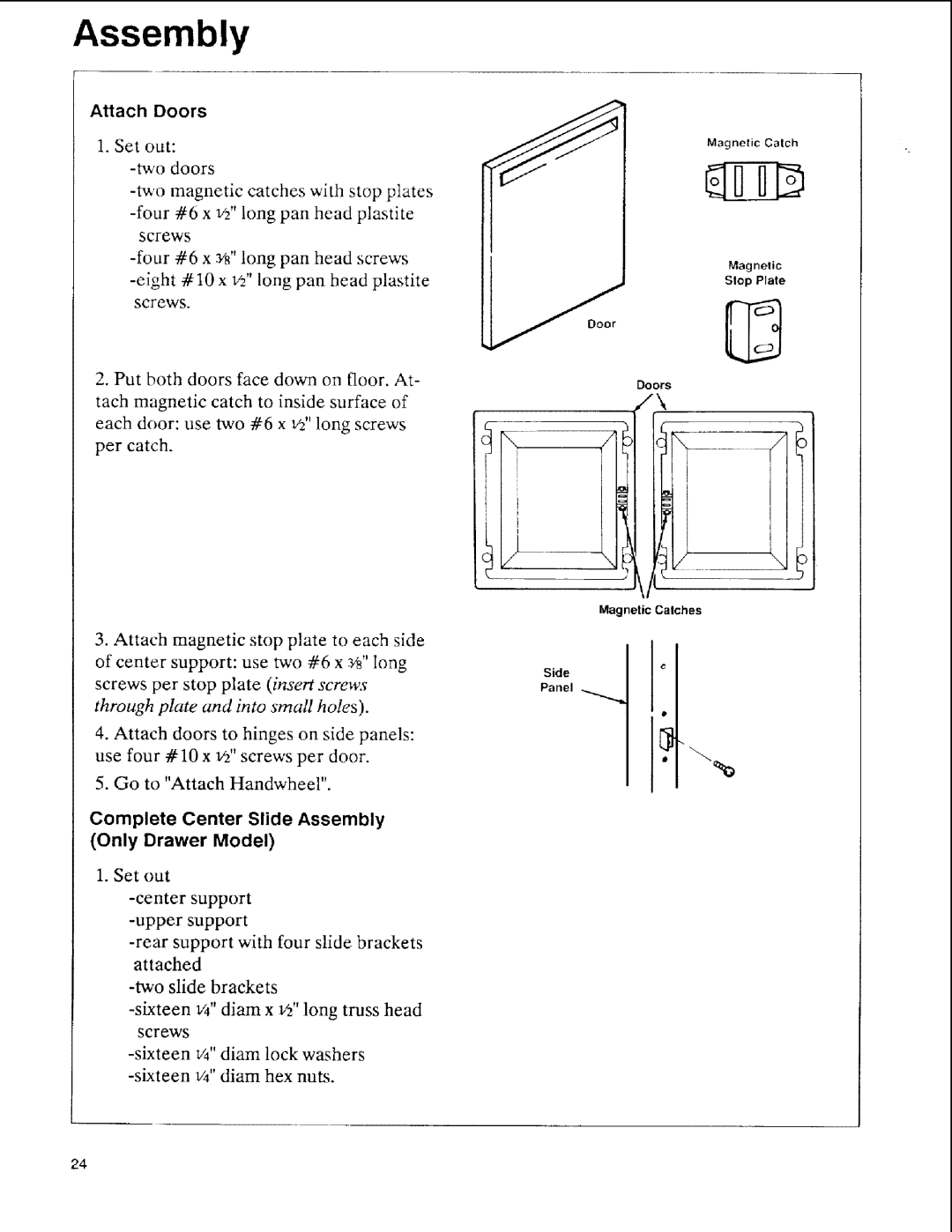

Attach Doors

Only Drawer Model

Center Support

Assemble Drawers

Attach Handwheel

Mount Motor

Shaft has left-hand threa&. Turn nut clock- wise to loosen

Assembly

Mount Basic Saw Assembly

Adjust Leveling Feet

Attach Trim Caps

Install Front Table

Attach Slide Arm Supports

Clips. Note Table will extend about Beyond Trim caps

Assemble Table Lock Mechanism

Alignment and Adjustment

Install Drawers Only Drawer Model

To Remove Drawers Only Drawer Model

Controls

45, -45 , 90

Rip l.ock

Controls

Alignment and Adjustment

Alignment and Adjustment Steps

Adjust Column Support

Level Front Table

Square Crosscut Travel

Install Blade

Square Blade to Table for Crosscut- ting

Alignment and Adjustment

Square Blade to Fence

Square Blade to Table for Ripping

Adjust Carriage Bearings

Make Blade Parallel to Table

Install Guard

Align Spreader to Blade

Complete Adjustments

Go to Digital Display Section and follow

Error Messages

Digital Display

Button Functions

=73

Install Battery

To Replace Battery

Align Encoders

Miter Encoder

Set Zero Reference Points For Bevel, Miter, and Elevation

Bevel Encoder

Set Zero Reference Point For Rip

Set Zero Reference Point For Out-Rip

Conversion Table

Motor Specifications

Power Supply

Motor Protection & Reset Button

Electrical Connections

To Change Motor Voltage to 240 A.C

To avoid electric shock, unplug saw

Before changing Motor voltage

Crosscutting Safety

Crosscutting

During crosscutting, blade teeth can

Having fingers, hand or arm cut off

Crosscuttin

Crosscut Kerfs

Making Crosscuts

Step

Repetitive Crosscutting

Ripping

Ripping Defined

In-Rip and Out-Rip Positions

Infeed and Outfeed Directions

Ripping Safety

Workpiece Positioning

Kickback

Pinching or binding can happen when

Ripping

Wrong Way Feed

Guard Nose Function

Pawls and Spreader Function

Ripping Set-up Procedure

If workpiece is pushed along fence

With kerfs, workpiece could get

Making Rip Cuts

Inleed

Ripping Hints

Dado Blades, Molding Heads

Cutting Aides

Fences

Push Sticks

Auxiliary Fence and Push Block for Ripping

Cutting Aides

Cutting Aides

Straight Edge for Irregular Workpiece

Accessories Safety

Information for Dado

Information for Edging

Lower Blade Guard

Edging without an auxiliary fence

Accessories

Lower blade guard can get caught or

Jam in fence or table kerfs

Maintenance

Cleaning

General Information

Lubrication

Adjustments for Wear

Remove screw and nut from swivel lock knob

Carriage Bearings

Arm and Column

Blade Changing

Replacing Pawls

Motor Problem

Possible Causes

What to Do

Troubleshooting

Troubleshooting

Cutting Problem

Saw Problem

Possible Causes

Troubleshooting

Electronics Problem

Blank

Repair Parts

Model NOS .197411 and 113.197511

Repair Parts

Always order by Part Number Not by Key Number

Model NOS .197411 and 113.197611

Base and Column Assembly

Model NOS .197411 and 113.197511

Parts List for Craftsman 10 Electronic Radial SAW

Model NOS .197411 and 113.197611

Model NOS .197411 and 113.197511

Model NOS .197411 and 113.197611 and 113,197511

Part

Repair Parts

ARM Assembly

Table Assembly

Foot Assembly Model 113.197511

Model NOS .197411, 113.197511

Repairs Parts

Model NOS .197411, 113.197511

Repairs Parts

Cabinet Assembly for Model 113.197411

For

Model

Motor Assembly

Guard Assembly

Index

Sold by SEARS, Roebuck and CO., Chicago, IL 60684 U.S.A

113.197411

Pail No. SP5539