Ripping

Ripping Set-up Procedure

Follow these steps before ripping. These

steps must be repeated each time a dif-

ferent thickness workpiece is ripped. A

kerr must be made for each different

width cut.

1. Prepare | table: |

|

|

|

|

|

auxiliary fence when blade is set 1/2to 2" | ||||||

from | fence) |

|

|

|

|

|

table | locks. |

|

|

| ||

2. Prepare | blade: |

|

|

|

| |

radial | arm | at | 0 ° miter |

| ||

motor | at | desired bevel | angle | |||

blade | in | position* |

| |||

blade | carriage | desired | distance | |||

from fence. Make sure wMest part of | ||||||

workpiece will be between blade and fence. | ||||||

*use | ||||||

set 12" or | more | from | fence |

| ||

3.Make kerf:

i)turn saw on

ii)lower blade about vl6" into table

iii)turn saw off and remove yellow key.

4.Place workpiece parallel to and up

against blade. Note: Workpiece wilt be be- tween blade and table front.

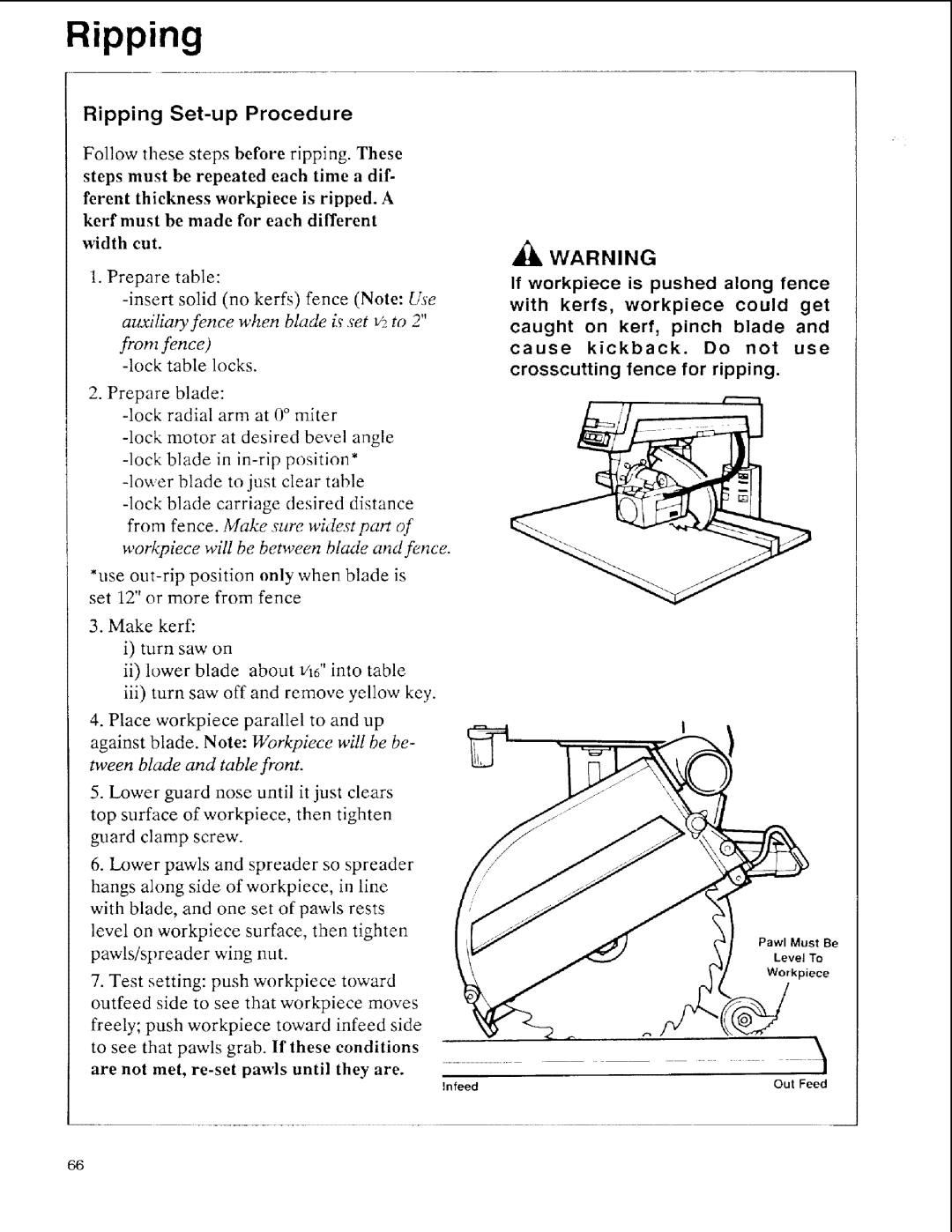

5.lower guard nose until it just clears

top surface of workpiece, then tighten guard clamp screw.

6.Lower pawls and spreader so spreader

hangs along side ofworkpiece, in line with blade, and one set of pawls rests

level on workpiece surface, then tighten

pawls/spreader wing nut.

7.Test setting: push workpiece toward outfeed side to see that workpiece moves

freely; push workpiece toward infeed side

to see that pawls grab. If these conditions

are not met,

Infeed

_, WARNING

If workpiece is pushed along fence

with kerfs, workpiece could get

caught on kerr, pinch blade and

cause kickback. Do not use

crosscutting fence for ripping.

Pawl Must Be

Level To

Workpiece

Out Feed

66