Crosscuttin

Repetitive Crosscutting

Repetitive crosscutting is the repeated

and continuous cutting of many pieces of lumber to the same length. Carriage and length stops can help make this type of

crosscutting more efficient. A lower blade

guard offers protection against the side of the blade (See Accessories).

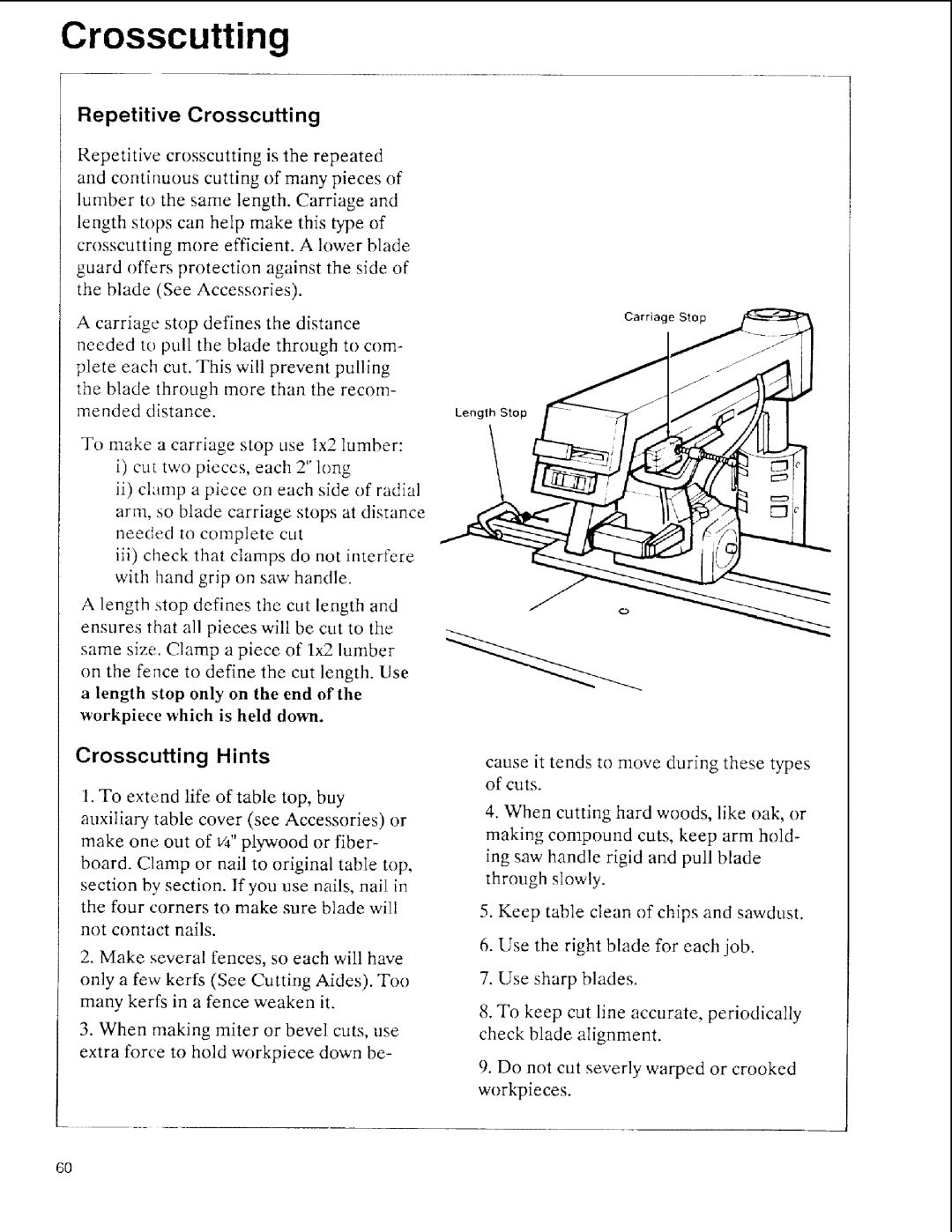

A carriage stop defines the distance needed to pull the blade through to com- plete each cut. This will prevent pulling the blade through more than the recom- mended distance.

To make a carriage stop use lx2 lumber:

i)cut two pieces, each 2" long

ii)clmnp a piece on each side of radial arm, so blade carriage stops at distance needed to complete cut

iii)check that clamps do not interfere with hand grip on saw handle.

A length stop defines the cut length and ensures that all pieces will be cut to the same size. Clamp a piece of lx2 lumber on the fence to define the cut length. Use a length stop only on the end of tile workpiece which is held down.

Crosscutting Hints

1. To extend life of table top, buy

auxiliary table cover (see Accessories) or make one out of */4"plywood or fiber- board. Clamp or nail to original table top, section by section. If you use nails, nail in the four corners to make sure blade will not contact nails.

2. Make several fences, so each will have only a few kerfs (See Cutting Aides). Too many kerfs in a fence weaken it.

3.When making miter or bevel cuts, use

extra force to hold workpiece down be-

Carriage Stop

Length Stop

cause it tends to move during these types of cuts.

4.When cutting hard woods, like oak, or making compound cuts, keep arm hold- ing saw handle rigid and pull blade through slowly.

5.Keep table clean of chips and sawdust.

6.Use the right blade for each job.

7.Use sharp blades.

8.To keep cut line accurate, periodically check blade alignment.

9.Do not cut severly warped or crooked workpieces.

6O