Guard Nose Function

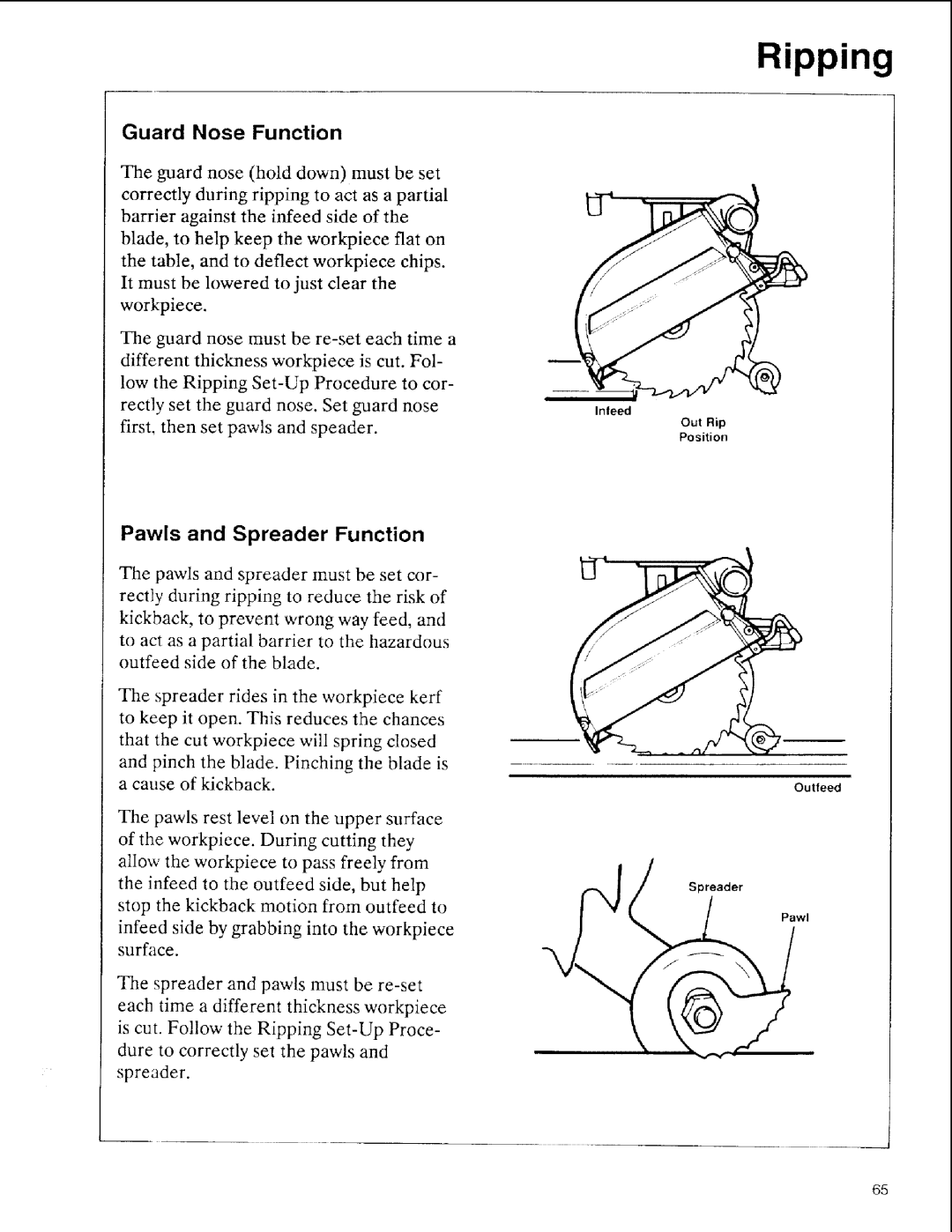

The guard nose (hold down) must be set correctly during ripping to act as a partial barrier against the infeed side of the

blade, to help keep the workpiece fiat on

the table, and to deflect workpiece chips. It must be lowered to just clear the workpiece.

The guard nose must be

low the Ripping

Ripping

Inleed

Out Rip

Position

Pawls and Spreader Function

The pawls and spreader must be set cor- rectly during ripping to reduce the risk of kickback, to prevent wrong way feed, and to act as a partial barrier to the hazardous outfeed side of the blade.

The spreader rides in the workpiece kerr to keep it open. This reduces the chances that the cut workpiece will spring closed and pinch the blade. Pinching the blade is a cause of kickback.

The pawls rest level on the upper surface of the workpiece. During cutting they allow the workpiece to pass freely from the infeed to the outfeed side, but help stop the kickback motion from outfeed to

infeed side by grabbing into the workpiece surface.

The spreader and pawls must be

Outfeed

Spreader

Pawl

65