Alignment and Adjustment

Make Blade Parallel to Table

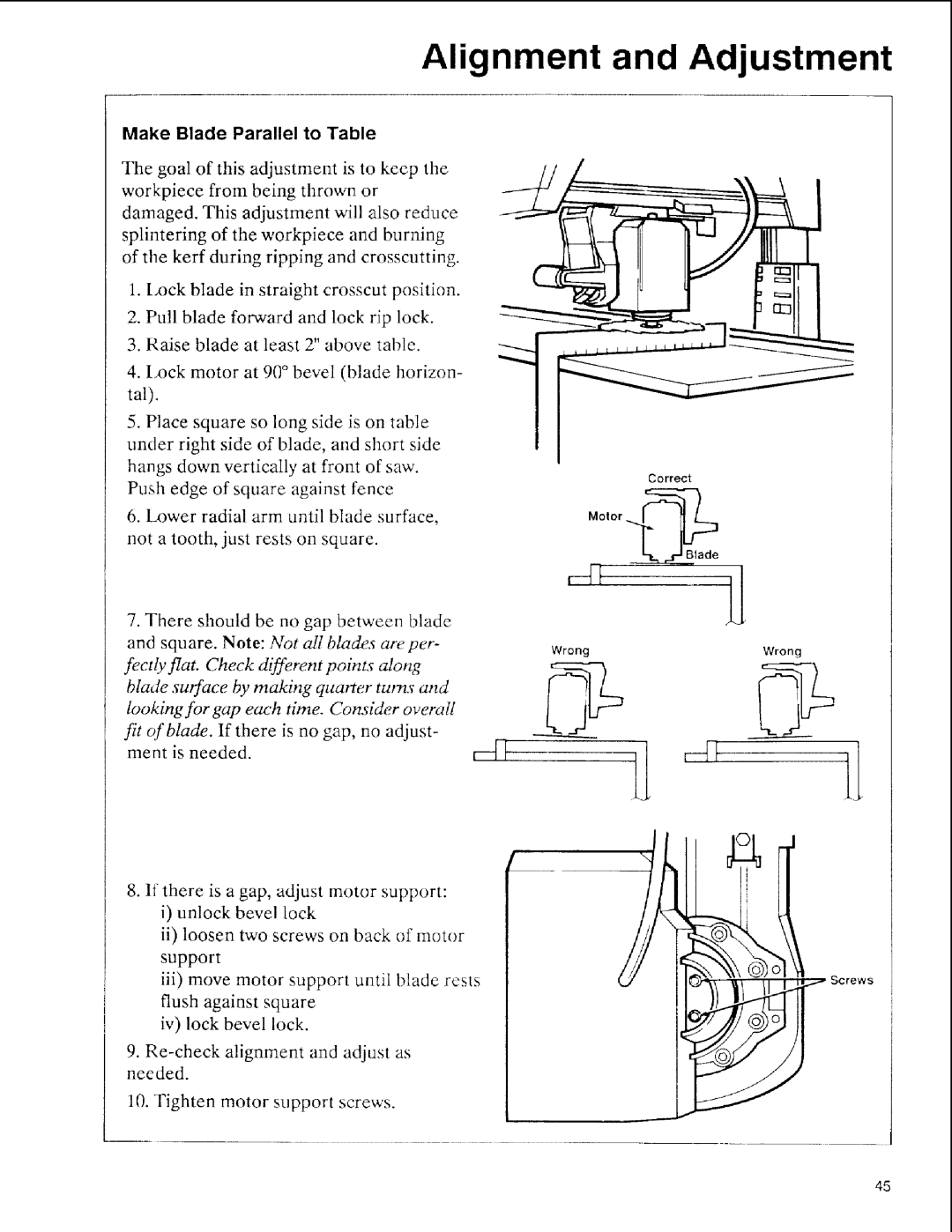

The goal of this adjustment is to keep the workpiece from being thrown or damaged. This adjustment will also reduce splintering of the workpiece and burning of the kerf during ripping and crosscutting.

1.Lock blade in straight crosscut position.

2.Pull blade forward and lock rip lock.

3.Raise blade at least 2" above table.

4.lock motor at 90 ° bevel (blade horizon- tal).

5.Place square so long side is on table under right side of blade, and short side hangs down vertically at front of saw. Push edge of square against fence

6.[x)wer radial arm until blade surface, not a tooth, just rests on square.

7.There should be no gap between blade

and square. Note: Not all blades are per-

fectIy flat. Check different points along blade surface by making quarter turns and

looking for gap each tbne. Consider overall

fit of blade, if there is no gap, no adjust- ment is needed.

8.if there is a gap, adjust motor support:

i)unlock bevel lock

ii)loosen two screws on back of motor support

iii)move motor support until blade rests flush against square

iv)lock bevel lock.

9.

needed.

10. Tighten motor support screws.

Correct

Motor

WrongWrong

11

45