Ripping

To reduce risk of kickback:

,/Set pawls and spreader according to ripping

,/Check that spreader is in line with

blade (see Alignment: Spreader to Blade).

,/Cut only straight workpieces so surface will lie flat on table and edge will stay tight against fence. If you must cut an ir- re_flar workpiece, attach a straight edge (see Cutting Aides).

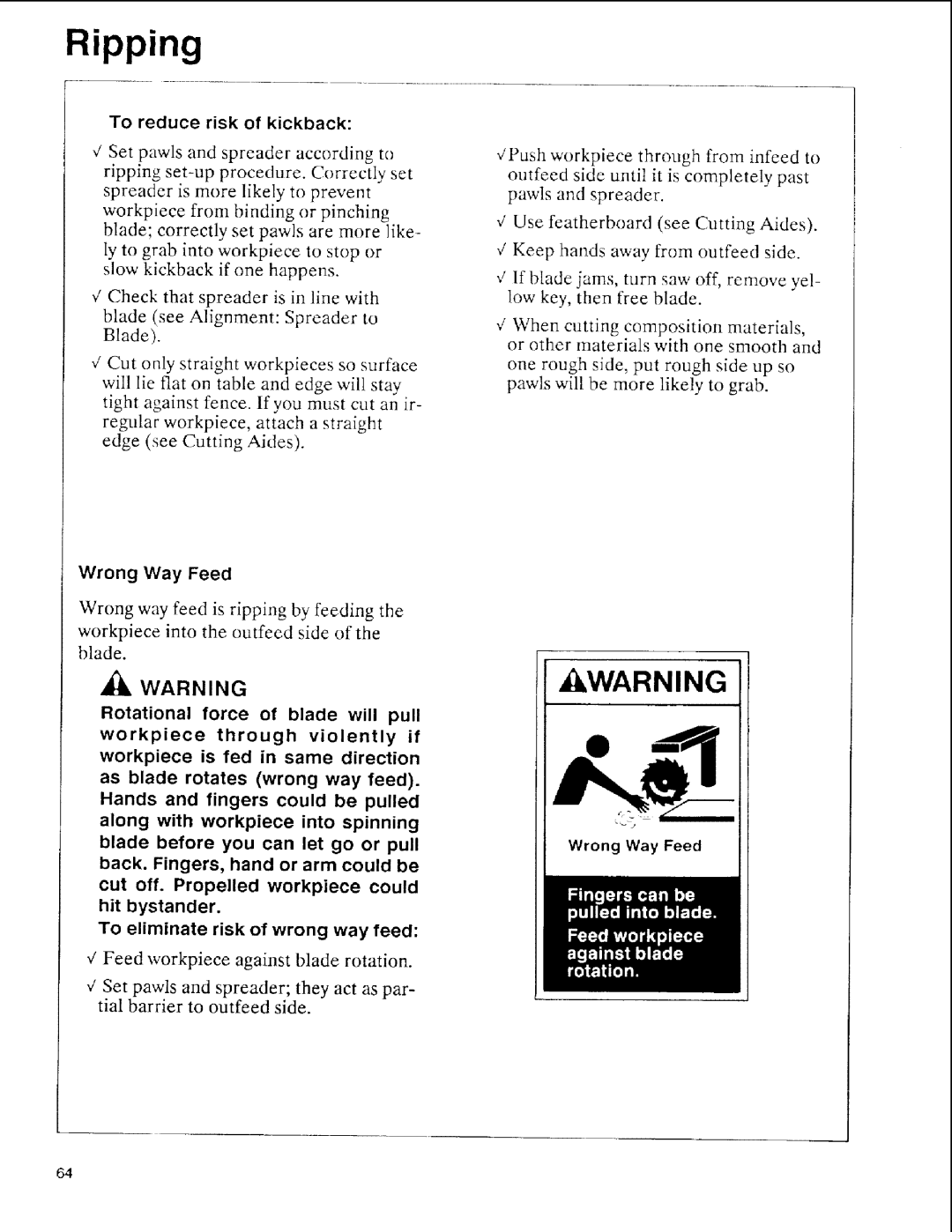

Wrong Way Feed

Wrong way feed is ripping by feeding the

workpiece into the outfeed side of the blade.

WARNING

Rotational force of blade will pull

workpiece through violently if workpiece is fed in same direction as blade rotates (wrong way feed). Hands and fingers could be pulled along with workpiece into spinning blade before you can let go or pull back. Fingers, hand or arm could be

cut off. Propelled workpiece could hit bystander.

To eliminate risk of wrong way feed:

,/Feed workpieee against blade rotation.

_/Set pawls and spreader; they act as par- tial barrier to outfeed side.

_'Push workpiece through from infeed to

outfeed side until it is completely past pawls and spreader.

_/Use featherboard (see Cutting Aides).

,I' Keep hands away from outfeed side.

_/If blade jams, turn saw oft', remove yel- low key, then free blade.

_ When cutting composition materials, or other materials with one smooth and

one rough side, put rough side up so pawls will be more likely to grab.

WARNING

Wrong Way Feed

64