General Information

When new, the saw requires no lubrica- tion. The saw has been partially aligned

and all bearings are lubricated and sealed for life. In time, in order to keep the saw in good working order, it will be necessary to clean, lubricate and

WARNING

To avoid shock, burns, or lacera- tions from accidental start up of saw, turn power switch off and unplug

saw before doing maintenance or servicing saw.

Cleaning

Periodically remove any heavy

sawdust that may accumulate on the saw. The absorbing tendency of sawdust will draw lubricants away from the areas where they are needed. Wipe the carriage bearings and track surfaces with a dry or lightly oiled cloth. If packed sawdust and

grease build up repeatedly on the carriage bearings, inspect the track wipers for wear and replace if necessary.

To avoid motor damage due to sawdust

Lubrication

Do not lubricate motor bearings, carriage bearings, or the area between the miter locking rings and the column tube. Motor and carriage bearings are sealed and do not need added lubrication.

You can lubricate other points if neces-

sary, but only when sticking or binding oc- curs. Use a small amount of SAE No

Maintenance

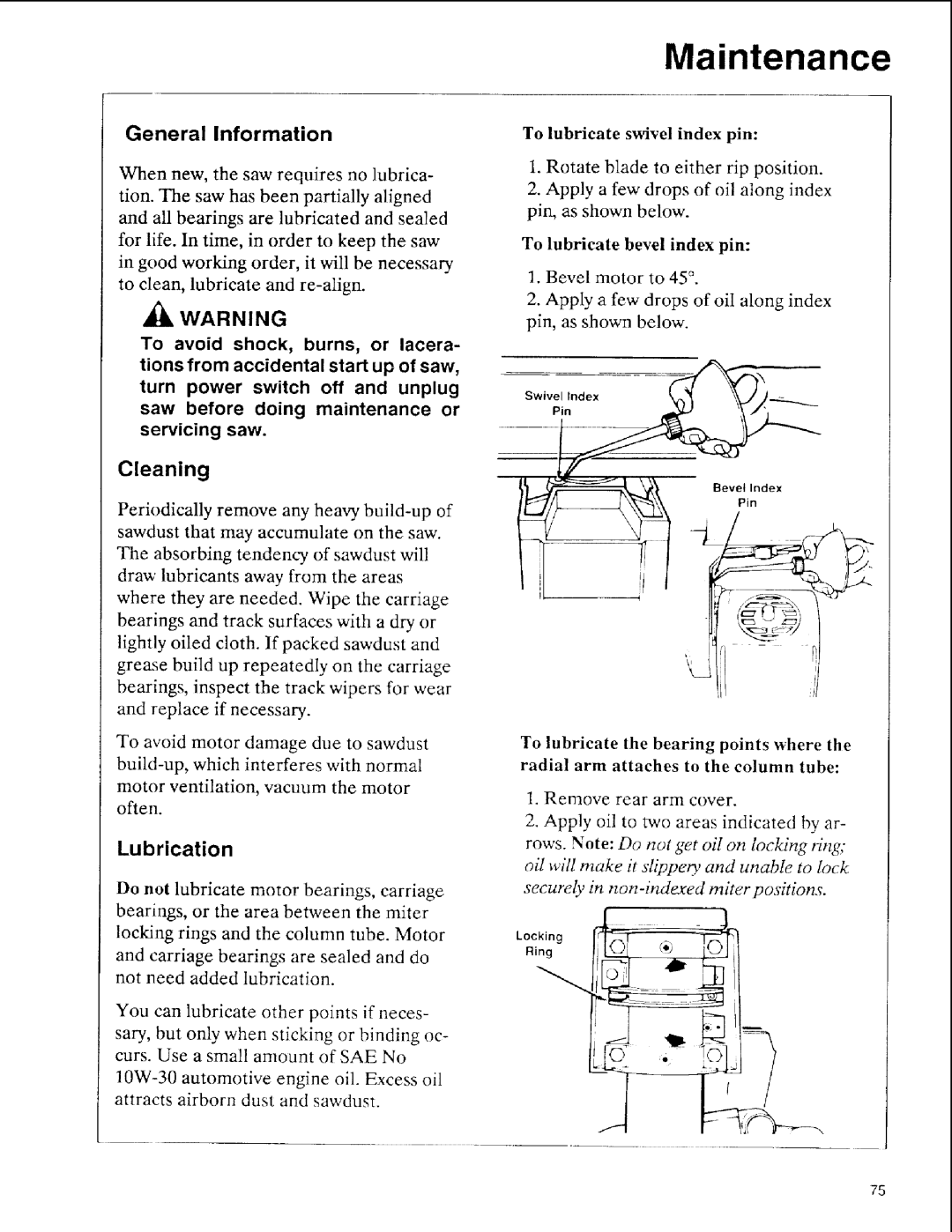

To lubricate swivel index pin:

1.Rotate blade to either rip position.

2.Apply a few drops of oil along index pin, as shown below.

To lubricate bevel index pin:

1.Bevel motor to 45 °.

2.Apply a few drops of oil along index pin, as shown below.

Swivel Index

Pin

Bevel Index

Pin

To lubricate the bearing points where the

radial arm attaches to the column tube:

1.Remove rear arm cover.

2.Apply oil to two areas indicated by ar-

rows. Note: Do not get oil on locking ring, oil will make it slippeq and unable to lock

securely in

Locking | &F | , | :]"_ |

75