ADDENDUM TO MODEL 101E OPERATORS MANUAL

MODEL 102E TOTAL REDUCED SULFUR ANALYZER

MODEL 501 TRS THERMAL CONVERTER

with

Page

05514 Rev A1

TABLE OF CONTENTS

M102E/M501 TRS

Addendum to M101E Manual - P/N 04740 Rev A

10. TROUBLESHOOTING & REPAIR

LIST OF APPENDICES

8. INSTRUMENT MAINTENANCE

9. THEORY OF OPERATION

PREFACE

LIST OF FIGURES

LIST OF TABLES

Page

1. PREFACE

corner of the display any time the instrument is in SETUP mode

User Notes

1.1. Reference Numbering convention

2.1.1. M501-TRS Specifications

2. SPECIFICATIONS, APPROVALS AND WARRANTY

2.1. Specifications

2.2. EPA Equivalency Designation

2.3. CE Mark Compliance

3.2. Unpacking the M501-TRS

3. GETTING STARTED

3.1. Unpacking the M102E

Never disconnect electronic circuit boards, wiring harnesses or

the maximum operating temperature specification for the M102E 40C

3.2.1. M501-TRS Ventilation Clearance

that the rack/enclosure itself is adequately ventilated

Figure 3-2 M501-TRS Internal Layout

3.3. Internal Layouts

Figure 3-1 M102E Internal Layout

M102E INSTRUMENT CHASSIS

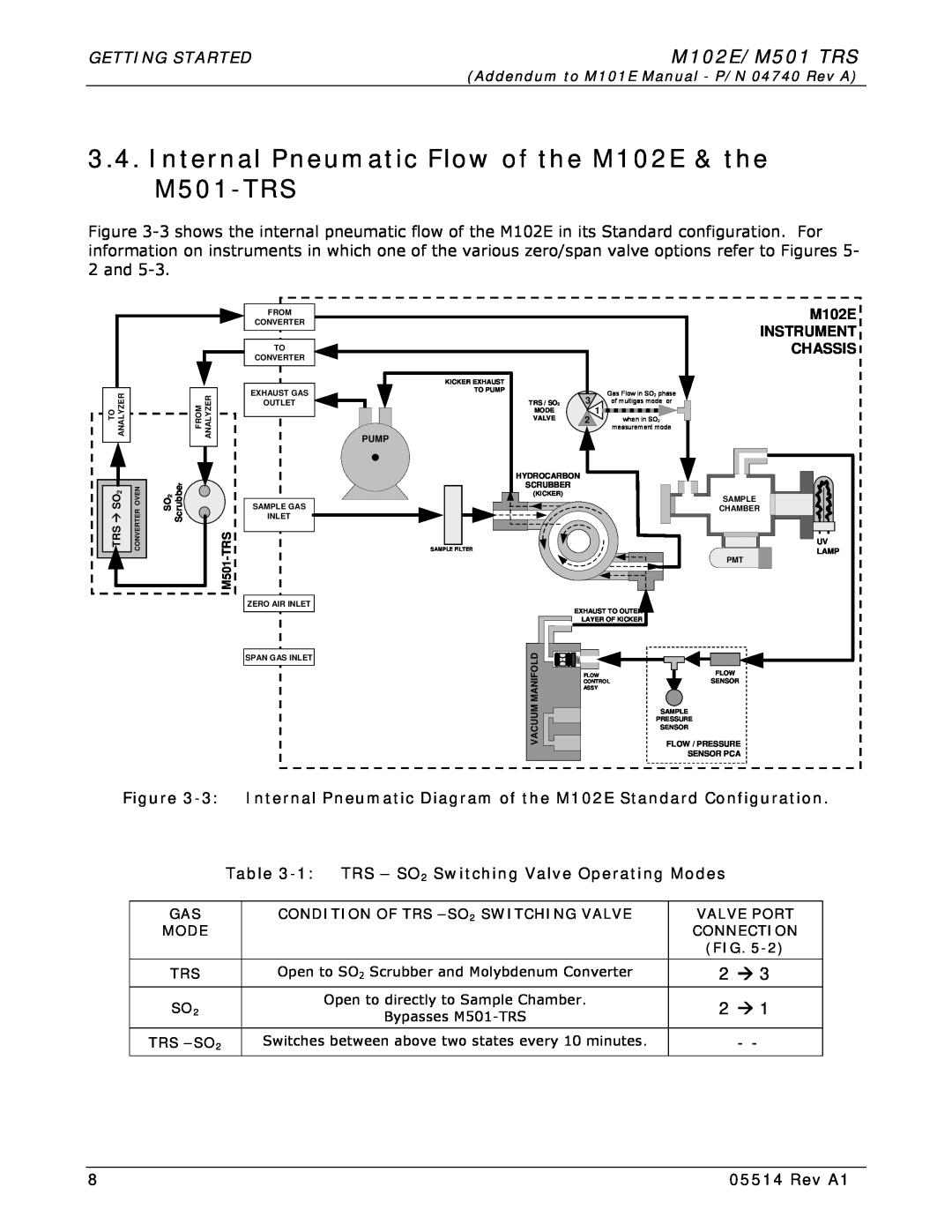

3.4. Internal Pneumatic Flow of the M102E & the M501-TRS

Table 3-1 TRS - SO2 Switching Valve Operating Modes

M501

Figure 3-4 M102E Rear Panel Layout

3.5. Rear Panel Layout for the M102E & M501-TRS

Alarm Output

5 Amp

3.6.1.1. M102E Analog Output Connections

3.6. Initial Setup

3.6.1. Electrical Connections

Figure 3-6 Analog Output Connector

M102E PNEMATIC CONNECTERS

3.6.1.2. M501-TRS Alarm Output Connections

3.6.2. Pneumatic Connections

M501-TRS PNEMATIC CONNECTERS

MODEL

102E

The exhaust from the instrument needs to be vented outside the

SPAN GAS

3.6.2.1. Connections with Internal Valve Options Installed

ZERO AIR

VENT if input is pressurized

Gas Dilution Calibrator

VENT

Option

Valve Option

3.7.2. Functional Check of the M102E

3.7. Initial Operation

3.7.1. Startup / Warm Up of the M102E

Possible Warning Messages at Start-Up

Process Variable

High Alarm LED Low Alarm LED

3.7.3. Startup / Warm Up of the M501-TRS

Display area

3.8. Initial Calibration

Page

4.2. Calibration Valves Options

4. OPTIONAL HARDWARE AND SOFTWARE

4.1. Rack Mount Kits Options 20a, 20b, 21, 22

OPTIONAL HARDWARE AND SOFTWARE

Zero/Span Valve Operating States

M102E INSTRUMENT CHASSIS

Table 4-2 IZS Valve Operating States

4.3.2. Addendum on CD Part number

4.3. Additional Manuals

4.3.1. Printed Manuals P/N

Figure 5-1 Analog Output Connector Key

5.1.1. M102E Analog Output Signals

5. M102E OPERATING INSTRUCTIONS

M102E OPERATING INSTRUCTIONS

5.2.1. M102E Analog I/O Configuration

5.2. SETUP - DIAG Using the Diagnostics Functions

5.1.2. Setting the M102E Gas Measurement Mode

Table 5-1 M102E gas Measurement Modes

5.3.1. M102E ID Code

5.3. SETUP - COMM Setting Up the M102E’s Communication Ports

5.2.2. M102E Test Channel Output

5.3.2. M102E Ethernet Host Name

CONTROL IN

5.4. Remote Operation of the Analyzer

5.4.1. Control Inputs

ZERO

5.4.2.1. M102E Hessen Protocol Gas ID List

5.4.2. Using the M102E with a Hessen Protocol Network

5 VDC Power Supply

SPAN

5.4.2.2. Setting Hessen Protocol Status Flags

Table 5-6 Default Hessen Status Bit Assignments

DO NOT OPERATE WITHOUT THE COVER OF THE M501TS CONVERTER INSTALLED

6. M501-TRS OPERATING INSTRUCTIONS

6.1. Basic M501-TRS Controls

Teledyne Instruments customer service

6.2. To Display The Current Temperature

Table 6-1 M501-TRS Temperature Controls and Definitions

6.3. To Manually Adjust the Converter Oven Temperature

DO NOT SET THE TEMPERATURE HIGHER THAN 1050OC

has reached a stable, constant temperature

6.4. Autotune the Temperature Controller

6.4.1. Initiating the Autotune Process

necessary to repeat the autotune procedure

6.5. M501TRS Alarm Relay Adjustment

6.4.2. Aborting the Autotune Process

Page

7.1. M102E Calibration

7. CALIBRATION PROCEDURES

USER NOTES

7.2. M501-TRS Calibration

Page

8. INSTRUMENT MAINTENANCE

INSTRUMENT MAINTENANCE

8.1.1. Maintaining the SO2 Scrubber

8.1. Additional and Updated Maintenance Procedures

8.1.1.1. Predicting When the SO2 Scrubber Should Be Replaced

8.1.1.2. Checking the Function of the SO2 Scrubber

8.1.1.3. Changing the SO2 Scrubber Material

Page

9.1.1. TRS Conversion

9. THEORY OF OPERATION

9.1. Measurement Principle

9.1.2. SO2 Ultraviolet Fluorescence

Ia = I0 1 − exp− axSO2

SO2 + hv214nm ⎯⎯Ia⎯→ SO2

SO2 * ⎯⎯→ SO2 + hv330nm

Figure 9-1 UV Absorption in the M102E Reaction Cell

Equation9-6

F = kSO2

kSO2 * ⎯⎯F⎯→ SO2 + hv330nm

9.2.1. UV Lamp Shutter & PMT Offset

9.2. The UV Light Path

9.3. Pneumatic Operation

9.3.1. Sample gas Flow

9.4.1. Sensor Module

PMT HOUSING

9.4. Electronic Operation

SAMPLE CHAMBERUV Lamp

Sample Air Housing Outlet O-Ring O-Ring Seal Seal

9.4.1.1. Sample Chamber

9.4.1.2. Sample Chamber Heating Circuit

Sample Air

HEATER

9.4.2.1. Thermal Switch

9.4.2. M501-TRS electronics

P-I-D CONTROLLER

9.4.2.2. Temperature Alarms and Alarm Output

10.1.1.2. M501-TRS Error Codes

10. TROUBLESHOOTING & REPAIR

10.1.1. Fault Diagnosis with Warning Messages

10.1.1.1. M102E Warning Messages

functioning

10.1.2. Fault Diagnosis with Test Functions

Table 10-2 Test Functions - Possible Causes for Out-Of-Range Values

10.2.1. TRS Converter Not Heating

10.2. M501-TRS Trouble shooting

10.3. Other Performance Problems

10.3.1. Excessive noise

10.4.2. Checking the Efficiency of the M501-TRS TRS Æ SO2 Converter

10.4. Subsystem Checkout

10.4.1. Checking the Efficiency of the M501-TRS SO2 Scrubber

10.5. Additional Repair Procedures

10.5.1. UV Lamp Adjustment and/or Replacement

Lamp Assembly

10.5.1.1. Adjusting the UV Lamp Peaking the Lamp

ALWAYS wear UV-Protective, Safety Glasses when working with the UV

Always grasp the main body of the lamp

10.5.1.2. Replacing the UV Lamp

Figure 10-1 Shutter Assembly - Exploded View

10.5.2. Replacing the UV filter/lens

Figure 10-2 Disassembling the Shutter Assembly

10.5.3. Replacing the PMT, HVPS or TEC

Figure 10-3 PMT Assembly - Exploded View

3. Remove the reaction cell assembly

10.5.4. M102E PMT Hardware Calibration FACTORY CAL

6. Locate the Preamp board see Figure

Figure 10-4 Pre-Amplifier Board Layout

Adjust the PMT until NORM PMT equals 1280 mV ± 10 mV

10.5.5. Replacing the TRS Converter Heating Tube

If a reporting range other than 500 ppb is used in this procedure

NORM PMT value of twice the ppb value of the span gas EXAMPLE

Be Careful

10.6. Manually Programming the M501-TRS Temperature Controller

The ceramic bobbins at each end of the heater assembly are fragile

element off

10.6.1. Temperature Controller Primary Menu Parameters

115V/60Hz with a set value of 1000C

Table 10-3 - Temperature Controller - Primary Parameter Settings

10.7. Technical Assistance

Table 10-4 - Temperature Controller - Primary Parameter Settings

M102E/M501 TRS

APPENDIX A-4 Model 102E Signal I/O Definitions

APPENDIX A - Version Specific Software Documentation

APPENDIX A-2 Model 102E Setup Variables Available Via Serial I/O

M102E/M501 TRS APPENDIX A - Version Specific Software Documentation

APPENDIX A-1 M102E Software Menu Trees, Revision A.2

SETUP

ENTER SETUP PASS

APPENDIX A-1 M102E Software Menu Trees, Revision A.2 SAMPLE

MSG 1,2

SAMPLE

TEST

CLR 1,3

TR2, 112, REPORTED

ACAL1

SO2, 111, REPORTED

DIAG

SAMPLE ENTER SETUP PASS

Figure A-4 Secondary Setup Menu DIAG

Table A-2

APPENDIX A-2 Setup Variables For Serial I/O, Revision A.2

Deleted Setup Variables for M102E Software Revision A.2

MEASUREMODE

Table A-4 Warning Messages deleted from M102 Software Revision A.2

setting of STABILFREQ and STABILSAMPLES

APPENDIX A-3 Warnings and Test Functions, Revision A.2

Table A-6 Test Functions Deleted from M102 Software Revision A.2

Rear board primary MUX analog inputs

APPENDIX A-4 M102E Signal I/O Definitions, Revision A.2

APPENDIX A-4 M102E Signal I/O Definitions, Revision A.2M102E/M501 TRS

CTEMPW

APPENDIX A-5 M102E iDAS Functions, Revision A.2

Trigger Event

Function

A-10

APPENDIX A-5 M102E iDAS Functions, Revision A.2

Table B-1 M102E Spare Parts List

APPENDIX B - M102E Spare Parts List

APPENDIX B - M102E Spare Parts List

M101E Manual - P/N 04740120 Rev A

05516 Rev A

TELEDYNE

Warranty/Repair Questionnaire Model 102E

M102E/M501 TRS

INSTRUMENTS

TELEDYNE

Table D-1 List of Included Electronic Schematics

APPENDIX D - ELECTRONIC SCHEMATICS

APPENDIX D - ELECTRONIC SCHEMATICS

Addendum to M101E Manual - P/N 04740 Rev A

M102E/M501 TRS

APPENDIX D - ELECTRONIC SCHEMATICS

User Notes

05518 Rev A

![]() CHASSIS

CHASSIS ![]()