Chapter 10 Adjustment

3. Adjustment of Clearance Between Needle and Rotary Hook

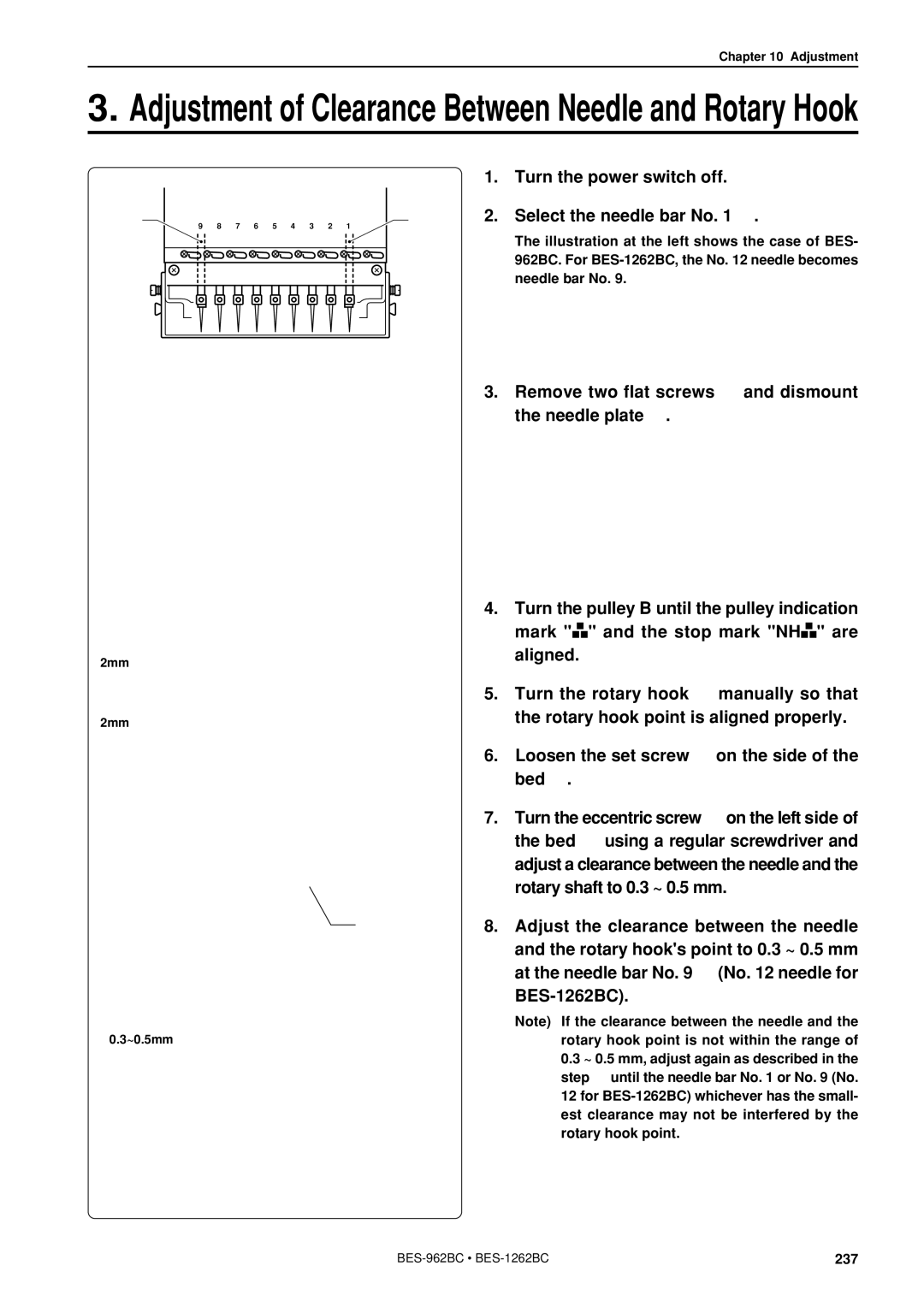

i | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 |

w

e

2mm

2mmr

u

t

y

0.3~0.5mm

1. Turn the power switch off.

q2. Select the needle bar No. 1 q.

The illustration at the left shows the case of BES- 962BC. For

3.Remove two flat screws w and dismount the needle plate e.

4.Turn the pulley B until the pulley indication mark "![]() " and the stop mark "NH " are aligned.

" and the stop mark "NH " are aligned.

5.Turn the rotary hook r manually so that the rotary hook point is aligned properly.

6.Loosen the set screw y on the side of the bed t.

7.Turn the eccentric screw u on the left side of the bed t using a regular screwdriver and adjust a clearance between the needle and the rotary shaft to 0.3 ~ 0.5 mm.

8.Adjust the clearance between the needle and the rotary hook's point to 0.3 ~ 0.5 mm at the needle bar No. 9 i (No. 12 needle for

BES-1262BC).

Note) If the clearance between the needle and the rotary hook point is not within the range of

0.3~ 0.5 mm, adjust again as described in the step r until the needle bar No. 1 or No. 9 (No. 12 for

237 |