|

| Chapter 12 Troubleshooting |

|

|

|

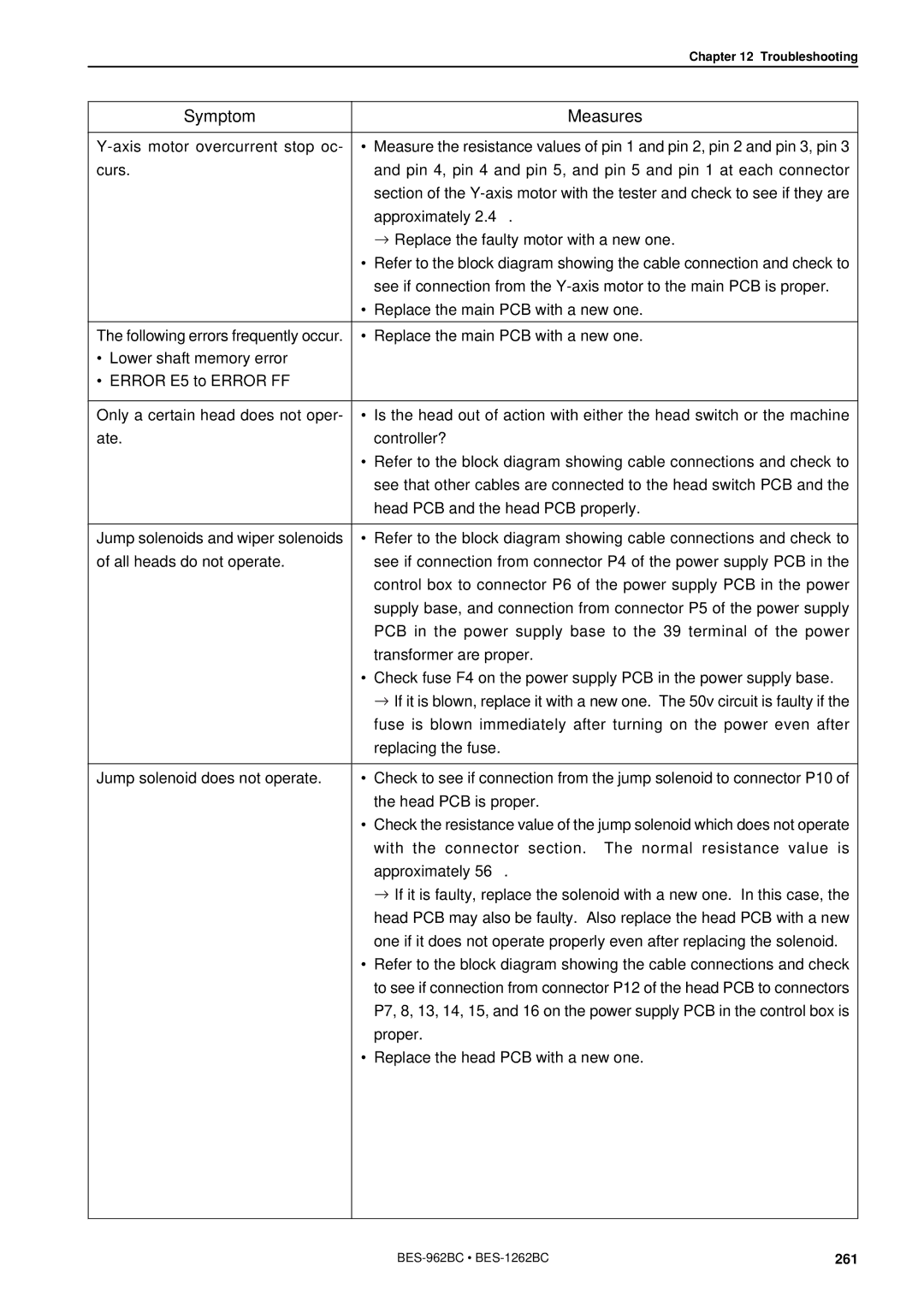

Symptom |

| Measures |

|

|

|

• | Measure the resistance values of pin 1 and pin 2, pin 2 and pin 3, pin 3 | |

curs. |

| and pin 4, pin 4 and pin 5, and pin 5 and pin 1 at each connector |

|

| section of the |

|

| approximately 2.4Ω. |

|

| Replace the faulty motor with a new one. |

| • | Refer to the block diagram showing the cable connection and check to |

|

| see if connection from the |

| • Replace the main PCB with a new one. | |

|

|

|

The following errors frequently occur. | • | Replace the main PCB with a new one. |

• Lower shaft memory error |

|

|

• ERROR E5 to ERROR FF |

|

|

|

|

|

Only a certain head does not oper- | • | Is the head out of action with either the head switch or the machine |

ate. |

| controller? |

| • | Refer to the block diagram showing cable connections and check to |

|

| see that other cables are connected to the head switch PCB and the |

|

| head PCB and the head PCB properly. |

|

|

|

Jump solenoids and wiper solenoids | • | Refer to the block diagram showing cable connections and check to |

of all heads do not operate. |

| see if connection from connector P4 of the power supply PCB in the |

|

| control box to connector P6 of the power supply PCB in the power |

|

| supply base, and connection from connector P5 of the power supply |

|

| PCB in the power supply base to the 39 terminal of the power |

|

| transformer are proper. |

| • | Check fuse F4 on the power supply PCB in the power supply base. |

|

| If it is blown, replace it with a new one. The 50v circuit is faulty if the |

|

| fuse is blown immediately after turning on the power even after |

|

| replacing the fuse. |

|

|

|

Jump solenoid does not operate. | • | Check to see if connection from the jump solenoid to connector P10 of |

|

| the head PCB is proper. |

| • Check the resistance value of the jump solenoid which does not operate | |

|

| with the connector section. The normal resistance value is |

|

| approximately 56Ω. |

|

| If it is faulty, replace the solenoid with a new one. In this case, the |

|

| head PCB may also be faulty. Also replace the head PCB with a new |

|

| one if it does not operate properly even after replacing the solenoid. |

| • | Refer to the block diagram showing the cable connections and check |

|

| to see if connection from connector P12 of the head PCB to connectors |

|

| P7, 8, 13, 14, 15, and 16 on the power supply PCB in the control box is |

|

| proper. |

| • Replace the head PCB with a new one. | |

|

|

|

261 |