8842A

Page

Table of Contents

Remote Programming

8842A

Measurement Tutorial

Maintenance

List of Replaceable Parts

Schematic Diagrams

List of Tables

805-7

List of Figures

805-8

IEEE-488 Interface PCA, Option True RMS AC PCA, Option

Xii

Introduction and Specifications

Options and Accessories

Introduction

8842A Digital Multimeter

Specifications

True RMS AC Voltage Option 8842A-09

Peak NM Signal

Rate

Filter

For Inputs

Frequency

Fundamental Frequency

Crest Factor

Current

Full Scale 5½ Digits

½ Digits

Through Unknown

Range Full Scale Resolution Current ½ Digits

Hours 23±1C

Function

Rate Power Line FREQUECNCY1

Automatic Settling Time Delay

Autoranging

Conversion Time ms 50 Hz 60 Hz 400 Hz

External Trigger Timing Characteristics

General

Power

Operating Instructions

Installation

Installing the Power-Line Fuse

Connecting to Line Power

Rack Mounting Kits

Adjusting the Handle

Operating Features

Power-Up Features

Front and Rear Panel Features

Operating Features

Local button causes the 8842A to display its

Rear Panel Features

Error Messages

Display Features

Meaning Error Code

Error Code

Autorange

Diagnostic Self-Tests

Overrange Indication

Ranging

Triggering

Continuous Trigger Mode

External Trigger Mode

Manual Range

Automatic Settling Time Delay

External Trigger Input Option -05 Only

Sample Complete Output Option -05 Only

Measuring Current

Making Measurements

Input Overload Protection Limits

Measuring Voltage and Resistance

Offset Measurements

Measuring Voltage and Resistance

External Cleaning

8842A

Remote Programming

Measurement Data Overrange Indication Error Messages

Capabilities

BUS SET-UP Procedure

IEEE-488 Address Selection

AN Overview of Remote Operation

AN Overview of Remote Operation

ExampleExplanation

DEVICE-DEPENDENT Command SET

DEVICE-DEPENDENT Command SET

Device-Dependent Command Set

Bn Offset Commands

Cn Calibration Commands

Dn Display Commands

Get Commands

Fn Function Commands

Meaning

Command Output String

12. G0 Get Instrument Configuration

13. G1 Get SRQ Mask

14. G2 Get Calibration Prompt

16. G4 Get Calibration Status

15. G3 Get User-Defined Message

19. G7 Get Error Status

17. G5 Get IAB Status

18. G6 Get YW Status

20. G8 Get Instrument Identification

Numeric Entry Command

Put Commands

23. P0 Put Instrument Configuration

25. P2 Put Calibration Value

24. P1 Put SRQ Mask

Rn Range Commands

Sn Reading Rate Commands

26. P3 Put User-Defined Message

Trigger Selection Logic Diagram

Tn Trigger Mode Commands

33. Z0 Self-Test Command

Wn Terminator Commands

31. X0 Clear Error Register Command

Yn Suffix Commands

Device-Clear Command

35. ? Single-Trigger Command

Input Syntax

Input Processing

Definitions

ERROR-PRODUCING Characters

DEVICE-DEPENDENT Messages

Interface Messages

Incorrect example

Syntax Rules

Loading Output Data

Output Data

Measurement Data

Numeric Data and Error Messages

Overrange Indication Error Messages

Types of Output Data

Output Priority

Error Messages

Overrange Indication

Status Data

Serial Poll Register

Service Requests

Set

SRQ Mask

Universal Commands

Interface Messages

Address Messages

Addressed Commands

TALK-ONLY Mode

Immediate Mode Commands

Remote Calibration

Timing Considerations

Example Programs

Immediate-Mode Commands for Various Controllers

Example Programs

10. Example Program Taking Readings with Local Control

11. Example Program Using the Serial Poll Register

12. Example Program Record Errors During Selftest

13. Example Programs Using the IBM PC

14. Example Programs Using the IBM PC

F3-1402.wmf

F3-1403.wmf

F3-1404.wmf

F3-1405.wmf

F3-1406.wmf

F3-1407.wmf

F3-1408.wmf

F3-1409.wmf

F3-1410.wmf

F3-1411.wmf

ASCII/IEEE Std 488-1978 Bus Codes

8842A

Measurement Tutorial

DC Voltage Measurement

Circuit Loading Error

Measuring Input Bias Current Error

Input Bias Current Error

Resistance Measurement

Wire Ohms

Correcting for Test Lead Resistance in 2-Wire Ohms

Full Scale Voltage

Test Current

Testing Diodes

Testing Electrolytic Capacitors

Applications of the Ohms Functions

Precision Current Source

DC Current Measurement

Reducing Thermal Voltages

Burden Voltage Error Calculation

AC Voltage and Current Measurement

True RMS Measurement

Waveform Comparison

AC Voltage and Current Measurement

AC-Coupled AC Measurements

Crest Factor

Zero-Input VAC Error

Combined AC and DC Measurements

Bandwidth

20Ω Ranges

Reduction of Zero-Input Error

10. Shielding for Low Voltage Measurements

Making Accurate HIGH-RESISTANCE Measurements

12. Leakage Resistance in High Resistance Measurement

Theory of Operation

True RMS AC Option VAC Scaling MA AC Scaling

Overall Functional Description

DC Scaling

Detailed Circuit Description

DC Scaling

DC Scaling VDC and mA DC

VDC Scaling

VDC Protection

MA DC Scaling

Analog Filter

Track/Hold Amplifier

TRACK/HOLD Circuit

TRACK/HOLD Circuit

Timing Diagram for One A/D Cycle

Track Configuration

Precision Voltage Reference

Settling Configuration

Hold Configuration

Pre-Charge Configuration

Ohms Current Source

Ohms Current Source

Ohms Functions

Ohms Protection

Ohms Scaling

20. A/D Converter

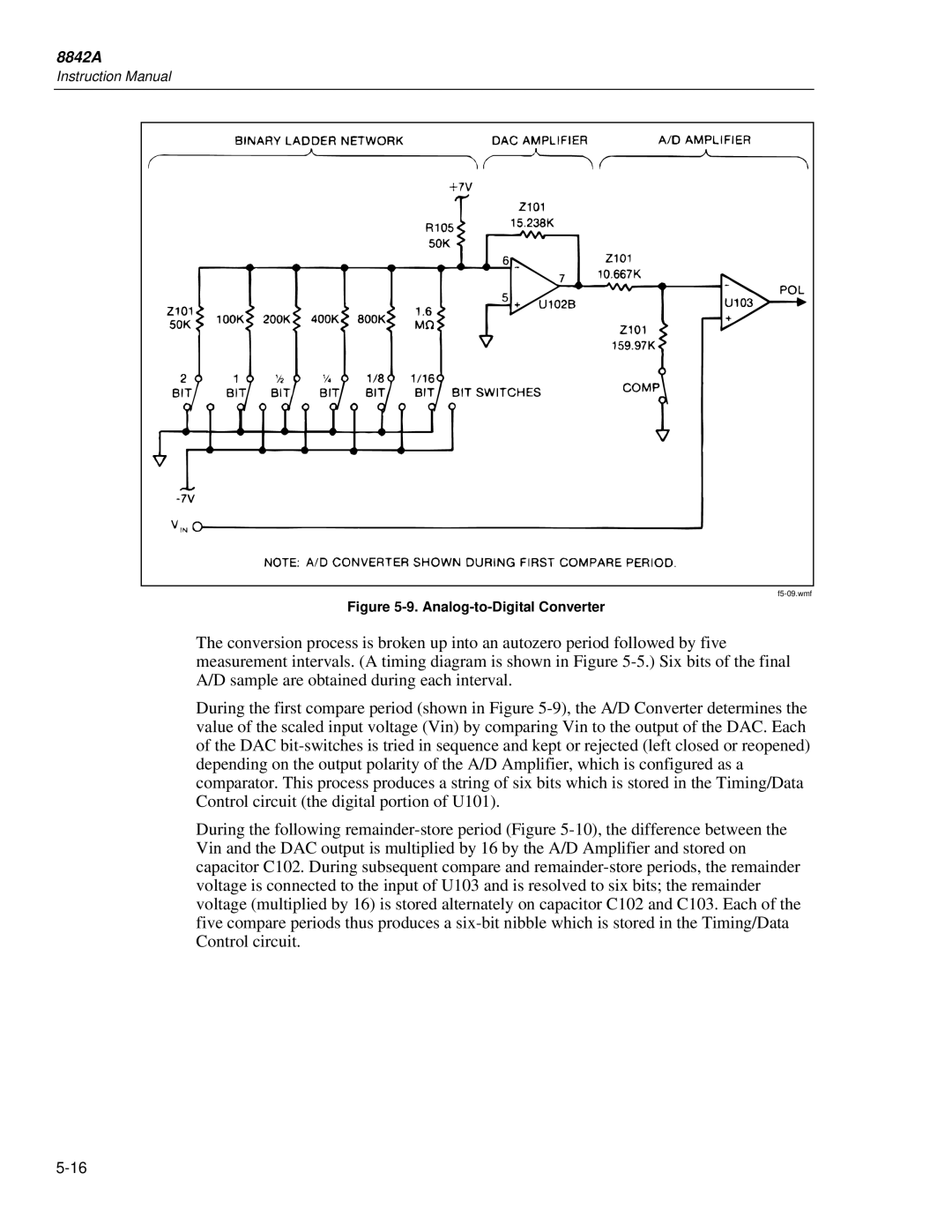

Analog-to-Digital Converter

Precision DAC

Timing/Data Control

Bootstrap Supplies

Display

23. A/D Amplifier

Digital Controller

Keyboard

13. Digital Controller Block Diagram

In-Guard Microcomputer

14. Read/Write Timing Diagrams for Internal Bus

Calibration Correction

Slow Medium Fast Power Line Frequency

Function and Range Control

30. A/D Control and Computation

Guard-Crossing Communication

Troubleshooting Modes

Guard Crossing

Keyboard/Display Control

Power Supply

Bus Interface Circuitry

IEEE-488 Interface Option

Out-Guard Microcomputer

Guard Crossing

Signal Conditioning

IEEE-488 Interface Power Supply

VAC Scaling

MA AC Scaling

Frequency Response Trimming

True RMS AC-to-DC Conversion

Static awareness

Dow Chemical

Maintenance

External Trigger Polarity Selection Option -05 Only

Instrument Type

Minimum Specifications Recommended Model

Frequency Range Minimum Required Accuracy All Ranges

Performance Test

DC Voltage Test

Slow Medium Fast MIN MAX

Step Range Input

Voltage Frequency

AC Voltage Test Option -09 Only

New Offset must be stored for each new range selected

Resistance Test

Fast MIN MAX

DC Current Test

Displayed Reading

Slow Medium MIN MAX

Input Current Frequency

Calibration

AC Current Test Option -09 Only

Step Number Range

Initial Procedure

Basic Calibration Procedure

Calibration Functions

12. A/D Calibration

L O W a B L E Error

Step Displayed Prompt

Step Input

Offset and Gain Calibration

Step

Displayed Prompt VDC VAC1

HIGH-FREQUENCY AC Calibration

Advanced Features and Special Considerations

Storing Variable Inputs

Step Displayed PROMPT1,2

Procedure Function LOW Prompt High Prompt

Calibrating Individual Ranges

Verifying Calibration

Tolerance Check

Erasing Calibration Memory

Tolerance

AC Calibration AT Other Frequencies

Optimizing USE of the 5450A

Calibration

Optimizing Use of the 5450A

Remote Calibration

Front Panel Feature

Corresponding Command

Comments

8842A

Timing Considerations

Example Calibration Program

Remote Erasure

Example A/D Calibration Program

Disassembly Procedure

Case Removal

A Disassembly

F6-062.wmf

F6-063.wmf

F6-064.wmf

True RMS AC PCA Removal Option -09 Only

IEEE-488 Interface PCA Removal Option -05 Only

Main PCA Removal

Maintenance

Front Panel Disassembly

Reassembly Procedure

Reassembly Procedure

Front Panel Disassembly

Removing the Display Window

Internal Fuse Replacement

Troubleshooting

Initial Troubleshooting Procedure

Troubleshooting

16. Overall State Table

T6-162.wmf

17. Circuitry Tested by the Analog Self-Tests

Diagnostic Self-Tests

Self-Test Descriptions

Test Number

Test Point Voltage

Maintenance

8842A

IN-GUARD Microcomputer System

Digital Controller Troubleshooting

In-Guard Microcomputer

Address Latch U219

Display System

Calibration Memory U220

Display Control U212

To-8 Strobe Decoder U213

Analog Control Signals

Device REF. DES

Evaluating Static Signals

21. Analog Control Logic States

DC Scaling Troubleshooting

Evaluating Dynamic Signals

Supply Voltage

PIN or Device

Ohms Current Source Troubleshooting

Track/Hold Troubleshooting

13. Typical Output Waveforms for Track/Hold Circuit TP103

Precision Voltage Reference Troubleshooting

14. Output of A/D Amplifier TP101

66. A/D Converter Troubleshooting

15. Waveforms at U101-24 and U101-25

For fire protection, use exact fuse replacement only

Power Supply Troubleshooting

17. Waveforms at TP102 for Several Inputs on 2V DV Range

Minimum Maximum

Test Point

IEEE-488 Interface Troubleshooting Option

Service Position

Diagnostic Program

Switches Configuration

Troubleshooting

Port BIT

True RMS AC Troubleshooting Option

Major Problems

Defective Ranges

Defective Stage

Input Voltage

Voltage AT TP801

Voltage AT TP802

More Obscure Problems

Internal Cleaning

Guard Crossing Troubleshooting

Cleaning Printed Circuit Assemblies

21. Guard Crossing Test Waveforms

Cleaning After Soldering

8842A

List of Replaceable Parts

8842A

Manual Status Information

HOW to Obtain Parts

Newer Instruments

Service Centers

Assembly Fluke Part no

REF of Option no

Revision Level

F7-011.wmf

F7-012.wmf

F7-013.wmf

F7-014.wmf

A1 Main PCA

CABLE, Display HEADER,1 ROW,.156CTR,6 PIN

8842A

F7-03.wmf

A2 Display PCA

F7-03.wmf

Supply Codes for Manufacturers

Supply2.wmf

Service Centers

Service2.wmf

8842A

Options and Accessories

8842A

Model

Description

Number Option

Accessories

Current Shunt 80J-10

Current Probes Y8100, Y8101, 80i-400

High Voltage Probes 80K-6 and 80K-40

8842A

Option -05 IEEE-488 Interface

805-2

External Controls

Maintenance

Programming Instructions

List of Replaceable Parts

List of Replaceable Parts

805-6

805-7

805-8

Option -09 True RMS AC

809-2

Option -09 True RMS AC

Operating Instructions

809-5

Option -09 True RMS AC PCA

809-7

809-8

Schematic Diagrams

8842A

Schematic Diagrams

F9-012.wmf

Main PCA, A/D Converter

F9-022.wmf

Main PCA, Ohms Current Source

F9-032.wmf

Main PCA, Digital

F9-042.wmf

Main PCA, Power Supply

F9-052.wmf

Display PCA

F9-062.wmf

F9-071.wmf

F9-072.wmf

IEEE-488 Interface PCA, Option

IEEE-488 Interface PCA, Option -08