DH Instruments, a Fluke Company

Operation and Maintenance Manual

RPM4

Page

Table of Contents

2RES Resolution 3STAB 4UL Upper Limit

Range Unit Mode

9RESET

Autorange Leak CK Display

115

MAINTENANCE, Adjustments and Calibration

Remote Operation

136

Pressure

137

Tables

Figures

Manual Conventions

About this Manual

RPM4 Operation and Maintenance Manual

Product Overview

Introduction

General Specifications

Specifications

Pressure Measurement Specifications

Quartz Reference Pressure Transducer Q-RPT

RPT

SI Version

Designation

US Version

ON-BOARD Barometer

Compensated Temperature Range 5 to 35 C

Predicted One Year Stability ± 0.005% of reading

RPTs UP to A10M 1500 psi

Battery and Charger Pack

RPM4 Operation and Maintenance Manual

Inspecting Contents

Installation

Unpacking and Inspection

Removing from Packaging

Site Requirements

Setup

Preparing for Operation

Front and Rear Panels

3.1 85 to 264 VAC, 50/60 HZ VAC Power

Power Connection

Battery Pack

Rear Panel

Connecting to Measure Pressure TEST+ and TEST- Ports

Remote ENT Connection Footswitch or Other Switch

CHECK/SET Security Level

Vent or ATM Port

Turn OFF Absolute and Negative Gauge Mode Axxx RPT

POWER-UP and Verification

Parallel Measurement Mode

Switch Power on

Check Pressure Measurement Operation

Checking Absolute Mode Pressure Measurement

Checking Gauge Mode Pressure Measurement

Short Term Storage

Main RUN Screen

Operation

User Interface

PRESSURE1UNITM hzRR DDISPLAYFUNCIONnn/nn

Display Field Name Purpose Contents Section

Function / Data Keypad Layout and Protocol

General Operating Principles

Remote ENT Enter Footswitch

Sounds

Pressure READY/NOT Ready

Multipe Ranges Q-RPTS, Autorange and Infinite Ranging

RPT Position

Display Symbol

Active A700K DF Hi psi 100g/100a

Setting Purpose Specific to Section

Using RPM4 with a PPC3 CONTROLLER/CALIBRATOR

SDS

Open and close SDS

AutoRange range

Measurement mode

Display

Range

To Charge the Battery

USE of the 12VDC BATTERY/CHARGER Pack

To Use the Battery/Charger Pack to Supply RPM4

To Check the Battery Charge Level

SDS Self Defense System

Direct Function Keys Summary

Direct Function Keys

Range

Summary of RPM4 Function Key Operation

Operation

Unit

Absolute

Mode

1kPa 2Pa 3MPa 4hPa 5bar 6mbar

Gauge

Measurement mode 1abs 2gage 3neg gage

Negative Gauge

Differential

Meas mode 1abs 2gage 3neg gage 4dif

Differential Measurement Mode Operation

Main run screen measured pressure display

Default Display function

SDS function

AutoZ function

Absolute mode Zero absolute

SETTING/SELECTION Purpose SET to Section

Negative gauge mode Minus

Gauge mode Q-RPT with

AutoRange A700K Hi kPa 300g/100a

Set leak check time 15 s

KPa a Leak testing 13 s

Leak CK

∆P 0.61 kPa a Hi Rate 0.06 kPa/sec

Display

1avg 2rate 3dev 4RPT 5HiLo 6freeze 7clean

Averaging Period

AVG Average

20 s

0007 18Avg

Psi a Hi

Rate

0001/sec

Current rate of change of pressure in current

Psi a zH3 D -0.8865 T100.0000

Dev Deviation

Target 100.0000 psi a

Psi a zHi Psi g zLo

6.4 RPT

Psi a zHi H 99.2254 L98.0098

6.5 Hi/Lo

Psi a zHi F

Clean

Freeze

Psi a zHi

Conventional main run screen first line Clean second line

Head

Edit head height

Principle

Position designator of Q-RPT for which SDS will be opened

Pmax! 350 kPa a Hi Open SDS? 1no 2yes

Pmax! 350 kPa a HL Open Hi&Lo? 1no 2yes

AU T O Z

SDS in Differential and Parallel Measurement Modes

Autoz in Gauge and Negative Gauge Mode

AutoZ Hi abs by 1Entry 2COM2 3Lo RPT

Autoz in Absolute Mode

KPa a Pstd,00.00000

Run AutoZ by Entry

Old Poffset 0.0 Pa New Poffset 8.3 Pa

Run AutoZ by COM2

KPa a Pstd,097.7786

Old Poffset 0.0 Pa New Poffset 3.1 Pa

Run AutoZ by Lo RPT

ENT RUN Autotest

Autoz in Differential Mode

1range 2res 3stab 4UL 5ATest

1RANGE

Saving AN Autorange Range

Deleting Autorange Ranges

2 2RES Resolution

Save range A700K Hi kPa 300g/100a

A700K Hi kPa 300g/100a

Display resltn Hi 0.0010 %FS

3 3STAB

Stability Hi 0.020 Pa

4 4UL Upper Limit

Upper Lower-110.00 KPa g

Upper limit Hi 204.000 kPa a

Special

1AutoZ 2remote 3head 4SDS 5prefs 6Punit 7intern 8cal 9reset

5 5ATEST

Over Pressure Function

AutoZ Purpose and Principle

1 1AU T O Z

AutoZ in absolute measurement mode with an Axxx Q-RPT

AutoZ in differential measurement mode

AutoZ in gauge measurement mode with a Gxxx or BGxxx Q-RPT

AutoZ ON/OFF

Recommendations for the Use of the AutoZ Function

Active Q-RPT designator

1off 2view 3edit Abs on

Poffset, Abs

2 2REMOTE

Edit Autoz

2.3 4FORMAT

2.1 1COM1, 2COM2

2.2 3IEEE-488

If a test fails

3 3HEAD

2.4 5RS232 SELF-TEST

SDS temporary Hi 1close 2open

4 4SDS

4.1 1TEMP OPEN/CLOSE

4.2 2FULL Time ON/OFF

5 5PREFS

SDS full time Hi 1on 2off

1ScrSvr 2sound 3time 4ID 5level

5.2 2SOUND

5.1 1SCRSVR

5.3 3TIME

Press SPECIAL, 5prefs, 3time. The display is

5.5 5LEVEL Security

5.4 4ID

Security Levels

Setup

Unit Mode

Function LOW Medium High Range

Leak CK Display Head SDS

RPM4 SNnnnn-xx Password pppppp

Password pppppp Disables password

6 6PUNIT

Selecting 1change user level brings up the restriction menu

Define user unit 1.000000 unit/Pa

Set up unit #6 Unit#6 1SI 2other 3altitude 4user

1SI

2OTHER 3ALTITUDE 4USER

1baro 2ReadRt 3RPT2x 4lo vnt 5log

7 7INTERNAL

7.1 1BARO

7.2 2READRT

Pressure Display Rate of Change Update

Auto read rate 1on 2off

% of range span/s

7.3 3RPT2X

Test- vent1auto 2open 3close 4view

7.4 4LO VNT

Operation See Sections 5.2

8 8CAL

7.5 5LOG

1sets 2units 3ATest 4cal 5all

9 9RESET

9.1 1SETS

9.2 2 Units

Reset Result See Section Unit

9.3 3ATEST

9.4 4 CAL

9.5 5 ALL

Reset Result See Section

All Q-RPT Calibration PA to zero, PM to

All SDS full time on 4.2 DH Instruments, a Fluke Company

Overview

Remote Operation

Interfacing

1 RS232 Interface

IEEE-488

Programming Formats

1.3 COM2

PIN # Function Description

Enhanced Program Message Format

Using Command Type Commands

Classic Program Message Format

Using Query Type Commands

Programming Messages

Commands

Command

Error Messagess

VER

Zoffset

Classic

Program Message Description Overview

Enhanced

#xx

Program Message Descriptions

Abort

Enhanced Reply Abort no reply if IEEE-488 Example Sent

Range

ARANGEn

Unit

Mode

AUTOZEROn=RUN

AUTOZEROn

‘state’

CALAMB=adder, mult CalDate

Calamb adder, mult CalDate

Adder

Mult

Date

CONTn

9999. Setting the value to ‘0’ disables the head correction

Defaults Head 0, cm, N2 Arguments Height

Classic GPIB=addr

Classic HEAD=height, units, fluid

LLn

L2 / L3

LLn =limit

Limit

MMODEn

NVENTn

Adder, mult CalDate

PCALn

PCALn= adder, mult CalDate

PRn

PRR

PRR

Qprr

QPRR?

RATEn

Rng

READYCKn

READRATEn

Period

RESET?

Reset

REMOTE?

RESn

SDSn

RPTn

Close

SDSAUTO, Sdsact

SDSAUTOn

Lower limits

Measurement is finished

An internal device failure has occurred

SS%n

Ready/Not Ready criteria

SSn

Hhmm

UCOEFn

ULn

UNITn unit , ref UNITn unitn , ref UNITn unitg , ref

UNITn

UNITn unita , ref UNITn unitd , ref

UNITn=unit , ref

Oper RQS/MSS ESB MAV Error RSR

Error Queue

Status Reporting System

Status Byte Register

←←← Output Queue ←←← Error Queue

RQS/MSS ESB MAV Error RSR

Oper

PON URQ

Ready Status Register

Standard Event Register

PON URQ CMD EXE DDE QYE RQC OPC

Meas Nrdy RDY

Ieee STD .2 Common and Status Program Messages

Program Message Descriptions

RSE

Bit 6 64 is reserved and cannot be set Remarks

Example Sent ∗RST? Enhanced Reply

RPM4 Operation and Maintenance Manual

Principle

Maintenance Adjustments and Calibration

Calibration of Quartz Reference Pressure Transducers Q-RPTS

Corrected reading = uncorrected reading PM + PA

PA and PM Coefficients

AS Received and AS Left Data

OIL or GAS Operated Q-RPTS A14M and Higher

Equipment Required

GAS Operated Q-RPTS, A10M and Lower

SET-UP and Preparation

Standard Class Q-RPTS

Recommended Calibration Point Sequence

Calibration Point Segment

Point Span

Verification of Premium Class Q-RPTs

Premium Class Q-RPTS

SPAN1

25 % 50 % 75 % 100 %

15 % 30 % 40 % 45 % 50 % 55 % 60 % 70 % 85 % 100 %

Calibration Point Sequence, Premium Class BGxxx Q-RPTs

Allow abs Neg g mode? 1yes 2no

RPT Calibration Using Caltool for Rpts Software

Editing and Viewing Q-RPT Calibration Information

000000

Absolute Neg g mode 1on 2off

Cal date20030325 Hi AbsPoffset 0.0 Pa

RPT CALIBRATION/ADJUSTMENT Without Caltool for Rpts Software

As left reading = non-corrected reading new PM + new PA

Adjustment of ON-BOARD Barometer

Non-corrected reading = corrected reading PA/PM + Poffset

Reloading Embedded Software Into Flash Memory

Power Supply Module

Subassembly Description and Location

Mini Micro Board

Micro Card

ON-BOARD Barometer

Driver Board

RPT Module

Display

Valve

RPT Module Pneumatic Schematics

Condition State

Valve Condition State

Axxx Q-RPT A10M with G15K or BGxxx

Symptom Probable Cause Solution

Troubleshooting

Access Restricted

Fatal Fault

Ready green Ready/Not Ready

Check RPT connection

Displayed in second line

SDS Closed is displayed

RPM4 Operation and Maintenance Manual

Remote ENT

Black wire White wire DH Instruments, a Fluke Company

Appendix

Pressure

Unit Conversion

To Convert from Pa To

Multiply by

Warranty

RPM4 Operation and Maintenance Manual

HL Q-RPT

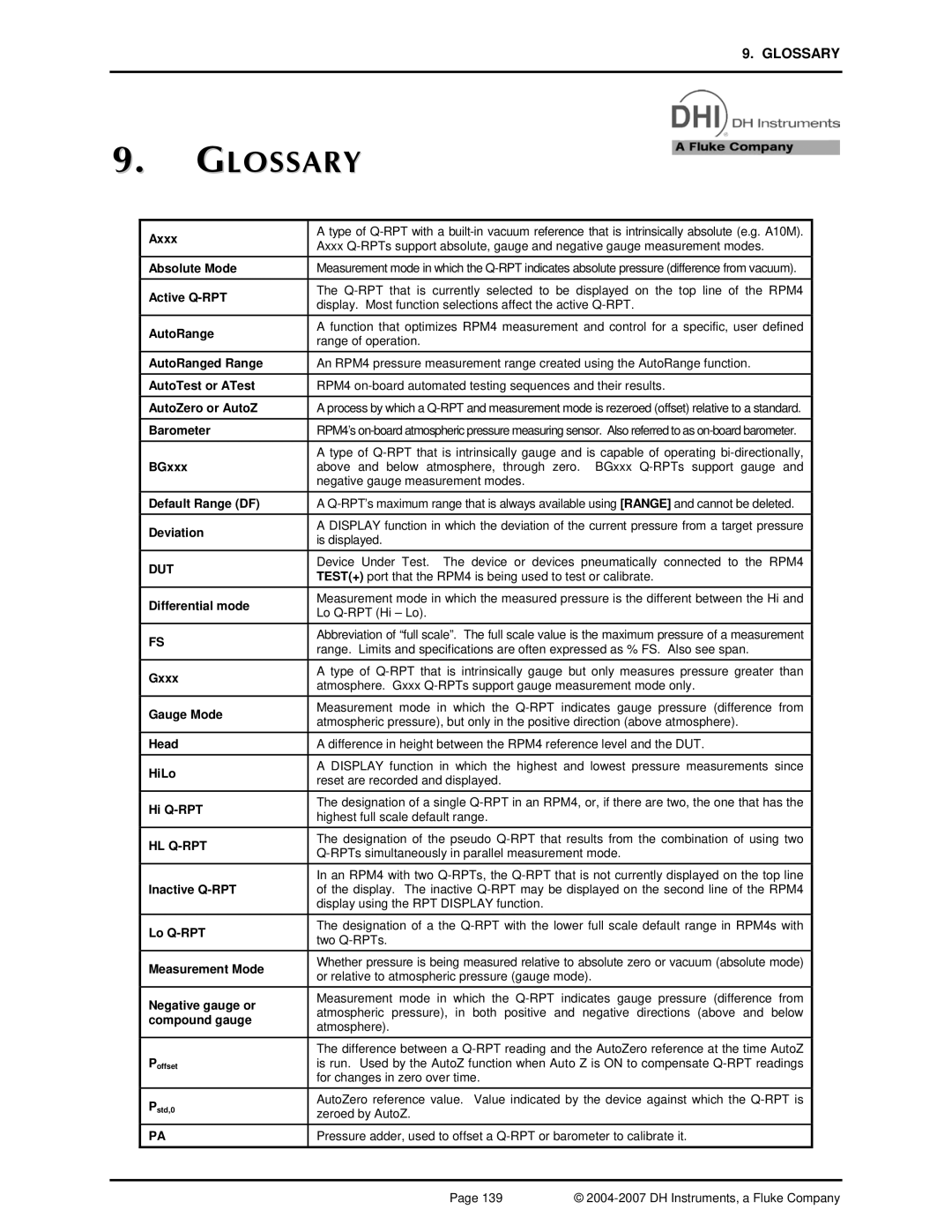

Glossary

DUT

Qdut

PPC3