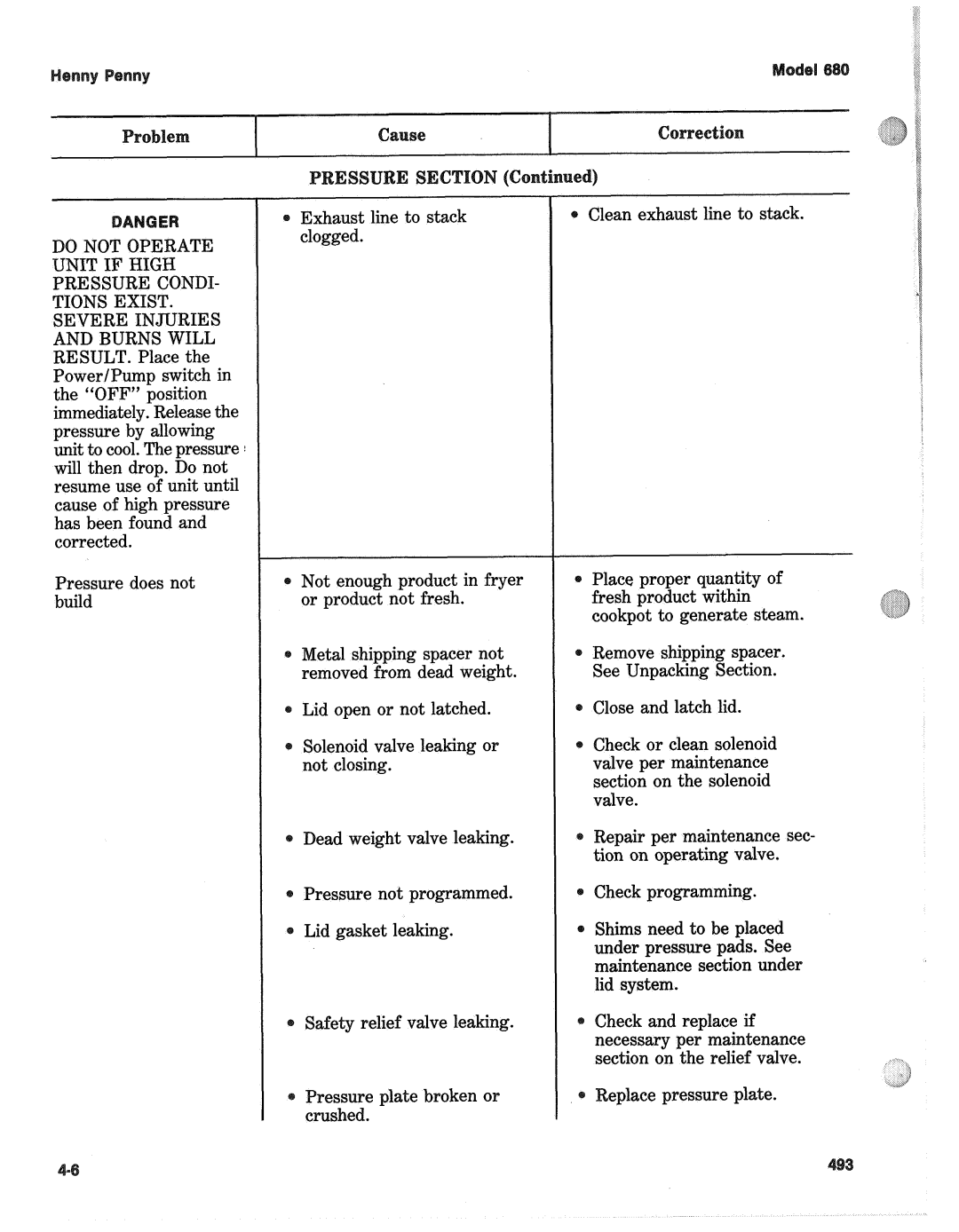

DONOTOPERATE UNIT IF HIGH PRESSURE CONDI- TIONS EXIST. SEVERE INJURIES AND BURNS WILL RESULT. Place the Power/Pump switch in the “OFF” position immediately. Release the pressure by allowing unit to cool. The pressure will then drop. Do not resume use of unit until cause of high pressure has been found and corrected.

Pressure does not build

Exhaust line to stack clogged.

Not enough product in fryer or product not fresh.

eta1 shipping spacer not removed from dead weight.

Lid open or not latched.

Solenoid valve leaking or not closing.

Dead weight valve leaking.

Pressure not programmed.

Lid gasket leaking.

Safety relief valve leaking.

Pressure plate broken or crushed.

Clean exhaust line to stack.

Place proper quantity of fresh product within cookpot to generate steam.

*Remove shipping spacer. See Unpacking Section.

Close and latch lid.

Check or clean solenoid valve per maintenance section on the solenoid valve.

Repair per maintenance sec- tion on operating valve.

Check programming.

Shims need to be placed under pressure pads. See maintenance section under lid system.

Check and replace if necessary per maintenance section on the relief valve.