Chapter 12. Protective functions

12.3 Stall prevention

Group

Function group 1

I/O group

LED | Parameter Name | Set | |

Display | value | ||

|

| F59 |

|

| [Stall prevention select] |

| - |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| F60 |

|

| [Stall prevention level] |

| - |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| I54 |

| 7 |

| |||

|

| terminal select] |

| ||||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| I55 |

| 7 |

| |||

|

| select] |

| ||||

|

|

|

|

|

|

| |

Min/Max setting

0/7

30/150

0/17

| Factory |

| Unit |

|

| default |

|

| |

|

|

|

| |

|

|

|

|

|

3 |

|

|

| |

150%

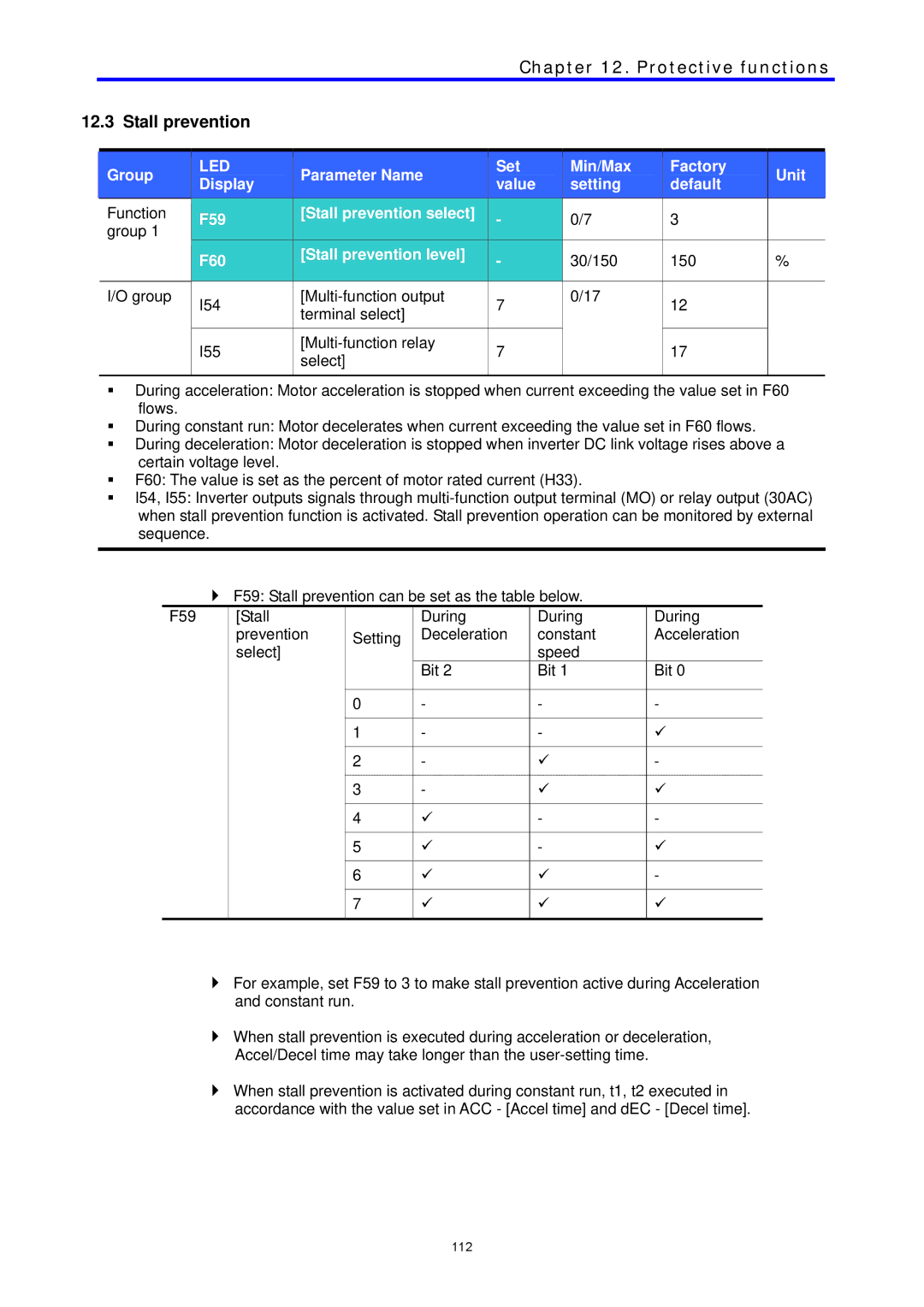

During acceleration: Motor acceleration is stopped when current exceeding the value set in F60 flows.

During constant run: Motor decelerates when current exceeding the value set in F60 flows.

During deceleration: Motor deceleration is stopped when inverter DC link voltage rises above a certain voltage level.

F60: The value is set as the percent of motor rated current (H33).

I54, I55: Inverter outputs signals through

F59: Stall prevention can be set as the table below.

F59 | [Stall |

| During | During | During |

| prevention | Setting | Deceleration | constant | Acceleration |

| select] |

|

| speed |

|

|

|

| Bit 2 | Bit 1 | Bit 0 |

|

|

|

|

|

|

|

| 0 | - | - | - |

|

|

|

|

|

|

|

| 1 | - | - | 9 |

|

|

|

|

|

|

|

| 2 | - | 9 | - |

|

|

|

|

|

|

|

| 3 | - | 9 | 9 |

|

|

|

|

|

|

|

| 4 | 9 | - | - |

|

|

|

|

|

|

|

| 5 | 9 | - | 9 |

|

|

|

|

|

|

|

| 6 | 9 | 9 | - |

|

|

|

|

|

|

|

| 7 | 9 | 9 | 9 |

|

|

|

|

|

|

For example, set F59 to 3 to make stall prevention active during Acceleration and constant run.

When stall prevention is executed during acceleration or deceleration,

Accel/Decel time may take longer than the

When stall prevention is activated during constant run, t1, t2 executed in accordance with the value set in ACC - [Accel time] and dEC - [Decel time].

112