BioOptix™ 10

Section 4 System Maintenance

Replacing the lamp | To install the new lamp: |

CAUTION

4.5 Troubleshooting

Contaminants on the glass bulb will shorten the life span. Oil from your skin is one such contaminant. Wear clean cotton gloves when handling the deuterium lamp.

1.Carefully insert the replacement bulb (part number

2.Route and secure the wires through the twist lock clamp.

3.Reconnect the wiring connector.

4.Replace the waste port mounting plate and secure it with the hardware.

Overall performance troubleshooting can be simplified if you maintain a system log that includes the number and type of samples that are separated.

If any difficulties or abnormal results are noted, they should be indicated in the log to assist in diagnosing any system problems.

It is worthwhile to maintain a standard sample that can be run periodically to check the overall performance of the system.

If you notice in your log that detector responses have changed, or you are running samples and the absorbance readings are not what you think they should be, you should run a standard.

If you run a standard sample and obtain the expected results, the problem is not being caused by the instrument. You can then examine other causes for your problem, such as the column or mobile phase.

4.5.1 Operating Problems

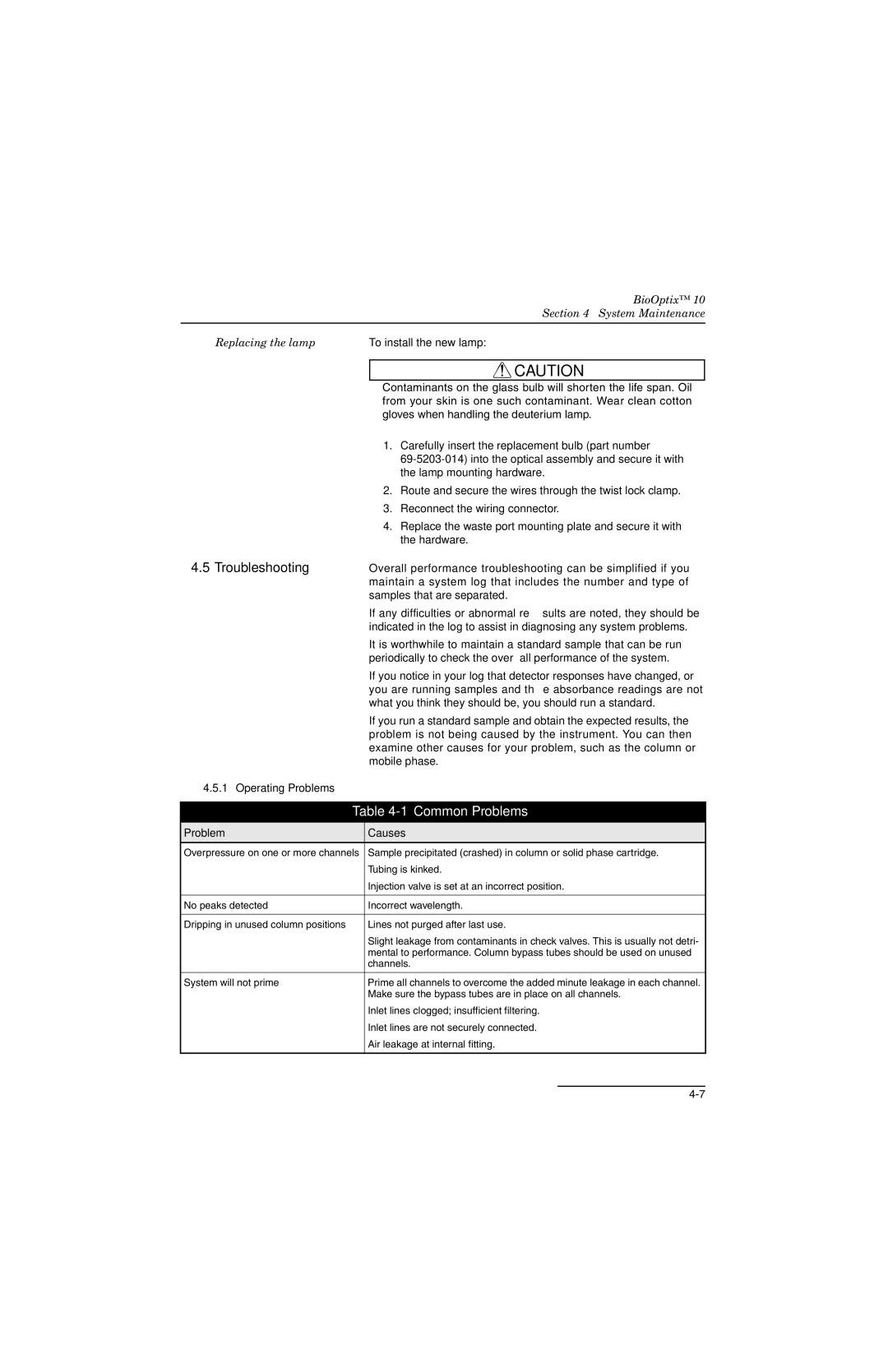

Table 4-1 Common Problems

Problem | Causes |

Overpressure on one or more channels | Sample precipitated (crashed) in column or solid phase cartridge. |

| Tubing is kinked. |

| Injection valve is set at an incorrect position. |

|

|

No peaks detected | Incorrect wavelength. |

|

|

Dripping in unused column positions | Lines not purged after last use. |

| Slight leakage from contaminants in check valves. This is usually not detri- |

| mental to performance. Column bypass tubes should be used on unused |

| channels. |

|

|

System will not prime | Prime all channels to overcome the added minute leakage in each channel. |

| Make sure the bypass tubes are in place on all channels. |

| Inlet lines clogged; insufficient filtering. |

| Inlet lines are not securely connected. |

| Air leakage at internal fitting. |

|

|