3 - Installation

conical | spacer |

|

|

| |

washer |

|

|

| ||

|

|

|

| ||

|

| 4 AWG | insert | cover | |

|

| tabs | |||

insulated |

| wire max. | |||

spacer | |||||

| |||||

|

| ||||

wire lug |

|

|

|

| |

(AMP |

|

|

|

| |

breakaway |

|

| connector |

| |

tab |

|

| assembly |

| |

|

|

| with bolt |

| |

|

|

|

| ||

|

|

| spacer | tighten | |

|

|

| cover | ||

|

|

|

| ||

|

|

|

| screw |

wires exiting at bottom | wires exiting at top | safety cover secured |

|

|

|

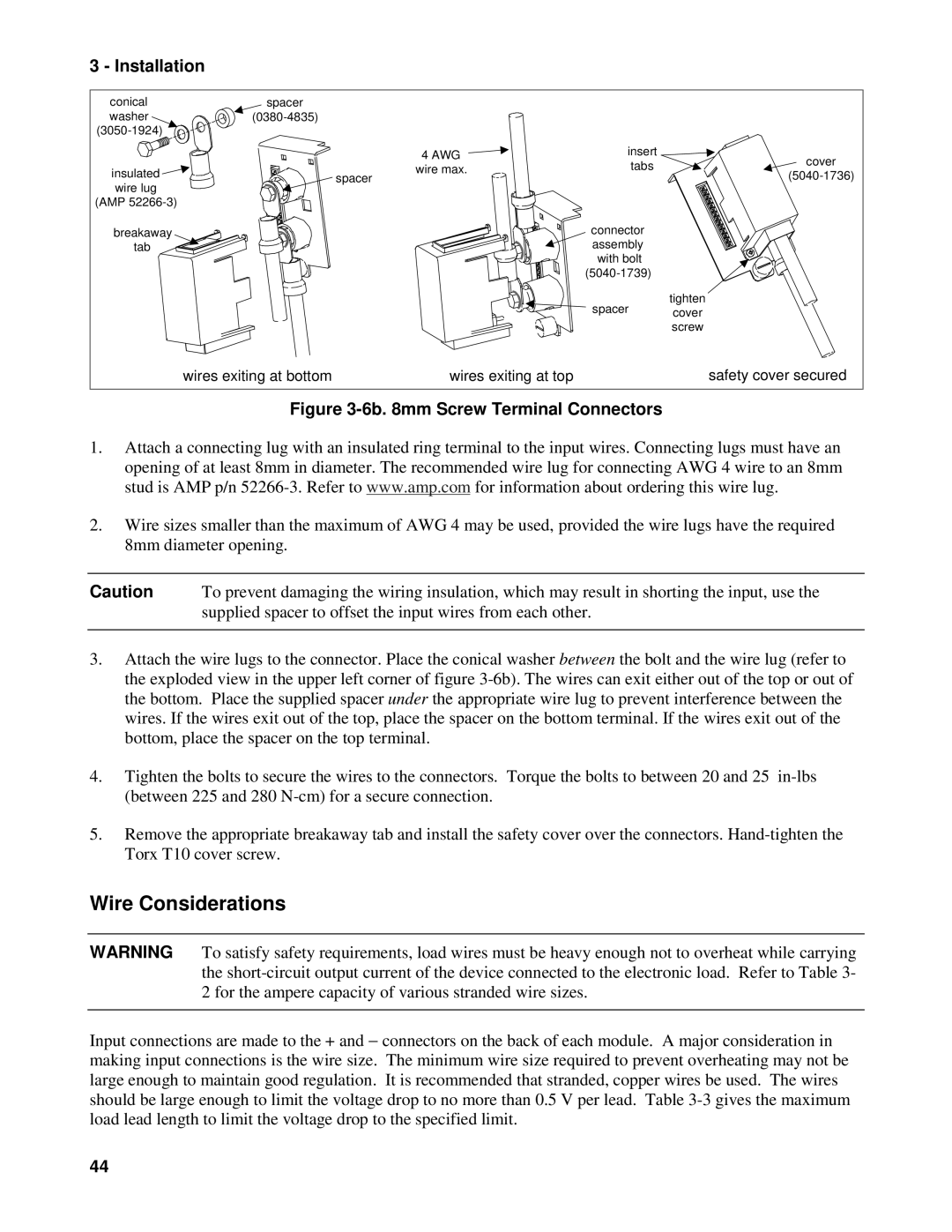

Figure 3-6b. 8mm Screw Terminal Connectors

1.Attach a connecting lug with an insulated ring terminal to the input wires. Connecting lugs must have an opening of at least 8mm in diameter. The recommended wire lug for connecting AWG 4 wire to an 8mm stud is AMP p/n

2.Wire sizes smaller than the maximum of AWG 4 may be used, provided the wire lugs have the required 8mm diameter opening.

Caution To prevent damaging the wiring insulation, which may result in shorting the input, use the supplied spacer to offset the input wires from each other.

3.Attach the wire lugs to the connector. Place the conical washer between the bolt and the wire lug (refer to the exploded view in the upper left corner of figure

4.Tighten the bolts to secure the wires to the connectors. Torque the bolts to between 20 and 25

5.Remove the appropriate breakaway tab and install the safety cover over the connectors.

Wire Considerations

WARNING To satisfy safety requirements, load wires must be heavy enough not to overheat while carrying the

Input connections are made to the + and − connectors on the back of each module. A major consideration in making input connections is the wire size. The minimum wire size required to prevent overheating may not be large enough to maintain good regulation. It is recommended that stranded, copper wires be used. The wires should be large enough to limit the voltage drop to no more than 0.5 V per lead. Table

44