Section 6 - Machine Operation

Machine Setup

The startup procedure given here is for a new machine that has just been installed.

1. Base Interface Cable

Attach the base interface cable from the rear of the base

to the back of the thruster housing as shown in Figures

2. AC Power

Insert the AC power plug (refer to Figure

Refer to the section on Electrical Safety in Chapter 2 if you have any questions. Ensure the AC Power Switch is

in the OFF position (see Figure

3. Attach Tooling

Attach the upper tooling to the hub and torque tightly.

The hub dimensions are given in Figure

the hub is intended to accept a

orientation. Place the lower fixture on the base and

attach it loosely so it can be aligned later.

4. Adjust Thruster Position on Column

The rear support column of the Dual Servo Spin Welder features a threaded shaft for adjusting the overall height of the thruster head. The adjustments are shown

in Figure

properly to ensure that the weld head has enough travel

to perform the weld (within the

and that the welded assembly can readily be removed

from the tooling. To adjust the position, complete the following steps:

a)Loosen the three rear nuts (which lock the head assembly in place). The nuts are 22mm wide, but a

b)Raise or lower the head by turning the adjustment lead screw on top, which is also a 22mm hex. The lead screw has 8 threads per inch, so 1 turn moves the head

(3.18 mm).

c)Tighten the rear locking nuts.

IMPORTANT

The Dual Servo Spin Welder is capable of developing substantial torque and high rotational velocity. Keep your hands and body away from the tool head during operation. The spinning head is capable of inflict- ing serious injury. Never attempt to retrieve a part from a spinning tool head. A l w a y s w e a r a f a c e s h i e l d w h e n operating the Dual Servo Spin Welder. Be extreme- ly careful not to let long sleeves, necklaces or long hair become entangled in the Dual Servo Spin Welder during operation.

Always turn machine power OFF when instalaling or removing the spin tool.

isttoReset |

Tw |

ER |

POW |

INCYCLE |

T |

ABOR |

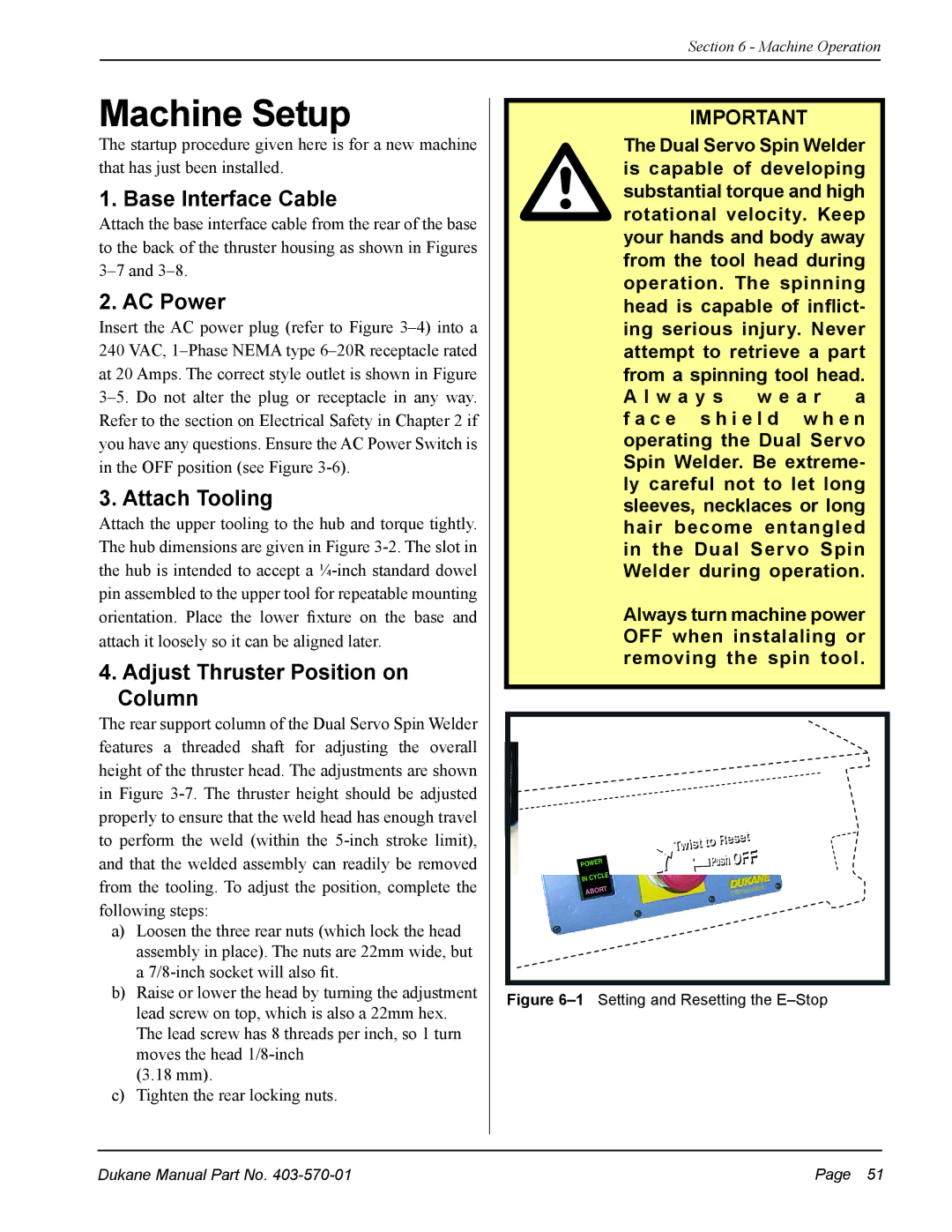

Figure 6–1 Setting and Resetting the E–Stop

Dukane Manual Part No. | Page 51 |