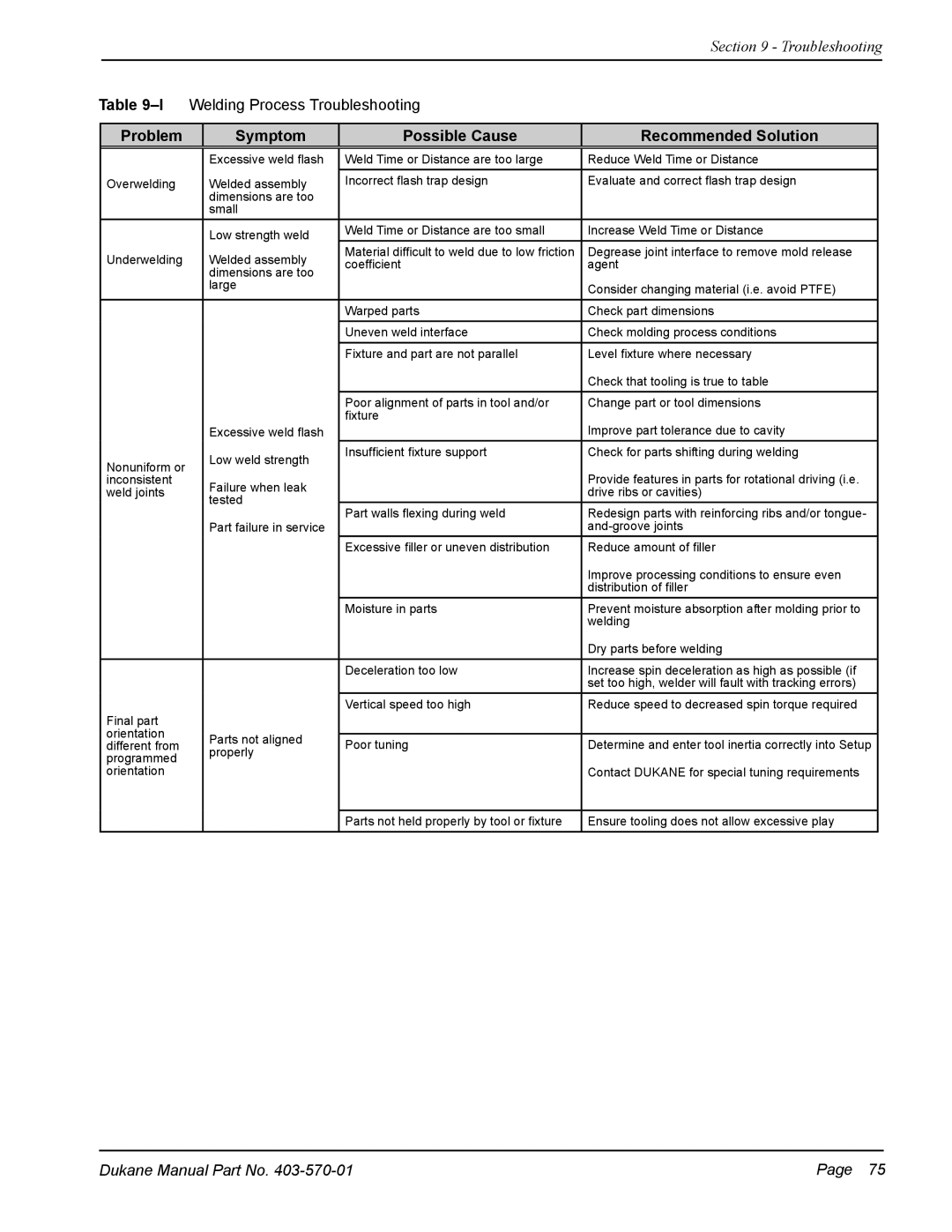

Section 9 - Troubleshooting

Table

Problem

Symptom

Possible Cause

Recommended Solution

| Excessive weld flash | Weld Time or Distance are too large | Reduce Weld Time or Distance | |

|

|

|

| |

Overwelding | Welded assembly | Incorrect flash trap design | Evaluate and correct flash trap design | |

| dimensions are too |

|

| |

| small |

|

| |

|

|

|

| |

| Low strength weld | Weld Time or Distance are too small | Increase Weld Time or Distance | |

|

|

| ||

Underwelding | Welded assembly | Material difficult to weld due to low friction | Degrease joint interface to remove mold release | |

coefficient | agent | |||

| dimensions are too | |||

|

|

| ||

| large |

| Consider changing material (i..e.. avoid PTFE) | |

|

|

| ||

|

|

|

| |

|

| Warped parts | Check part dimensions | |

|

|

|

| |

|

| Uneven weld interface | Check molding process conditions | |

|

|

|

| |

|

| Fixture and part are not parallel | Level fixture where necessary | |

|

|

| Check that tooling is true to table | |

|

|

|

| |

|

| Poor alignment of parts in tool and/or | Change part or tool dimensions | |

|

| fixture |

| |

| Excessive weld flash |

| Improve part tolerance due to cavity | |

| Low weld strength | Insufficient fixture support | Check for parts shifting during welding | |

Nonuniform or |

|

| ||

|

| Provide features in parts for rotational driving (i..e.. | ||

inconsistent | Failure when leak |

| ||

weld joints |

| drive ribs or cavities) | ||

tested |

| |||

|

|

| ||

| Part walls flexing during weld | Redesign parts with reinforcing ribs and/or tongue- | ||

|

| |||

| Part failure in service |

| ||

|

| Excessive filler or uneven distribution | Reduce amount of filler | |

|

|

| Improve processing conditions to ensure even | |

|

|

| distribution of filler | |

|

|

|

| |

|

| Moisture in parts | Prevent moisture absorption after molding prior to | |

|

|

| welding | |

|

|

| Dry parts before welding | |

|

|

|

| |

|

| Deceleration too low | Increase spin deceleration as high as possible (if | |

|

|

| set too high, welder will fault with tracking errors) | |

|

| Vertical speed too high | Reduce speed to decreased spin torque required | |

Final part |

|

|

| |

orientation | Parts not aligned |

|

| |

Poor tuning | Determine and enter tool inertia correctly into Setup | |||

different from | ||||

properly | ||||

programmed |

|

| ||

|

|

| ||

orientation |

|

| Contact DUKANE for special tuning requirements | |

|

|

|

| |

|

| Parts not held properly by tool or fixture | Ensure tooling does not allow excessive play | |

|

|

|

|

Dukane Manual Part No. | Page 75 |