Dual Servo Spin Welder User’s Manual

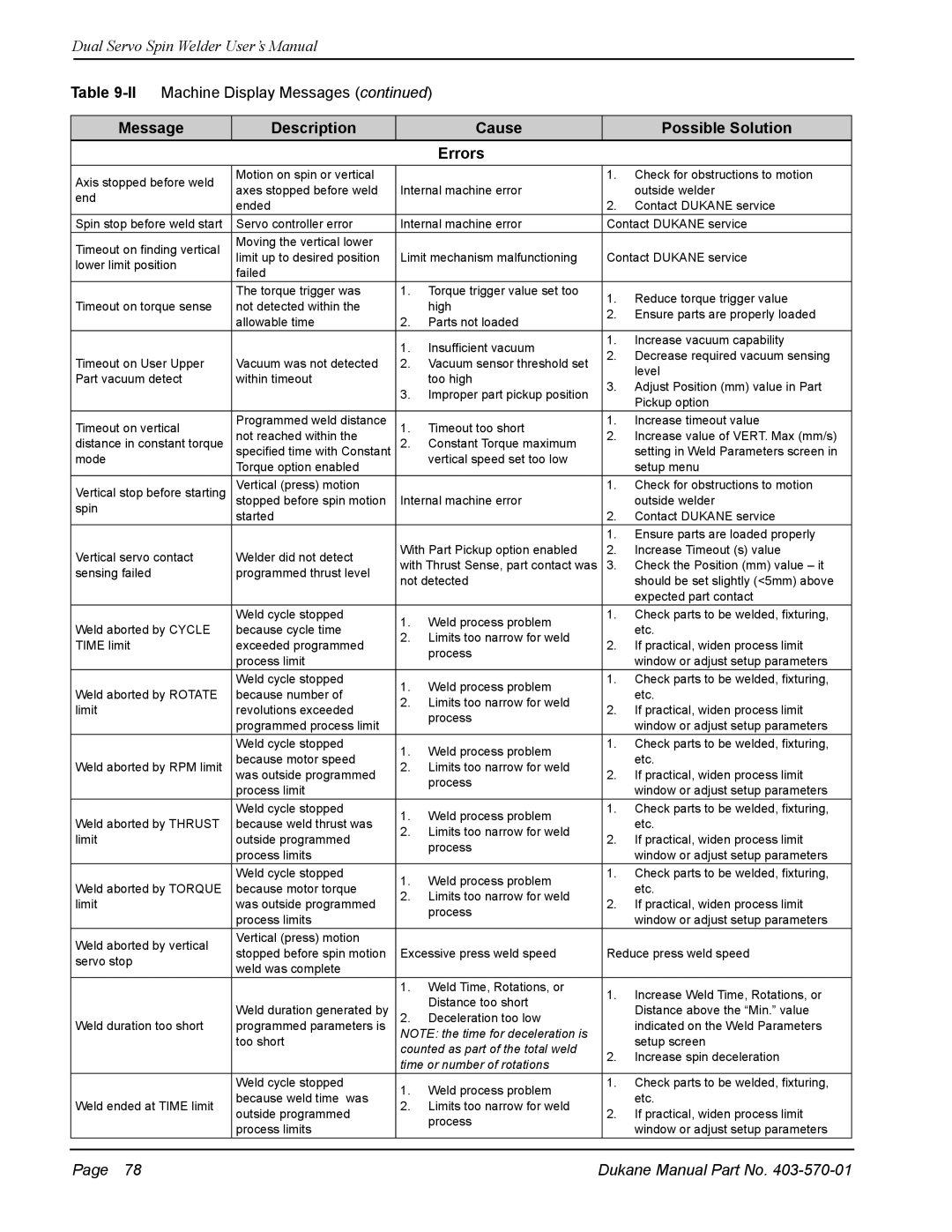

Table | Machine Display Messages (continued) |

|

|

| |||

|

|

|

|

|

|

| |

Message | Description |

| Cause |

| Possible Solution |

| |

|

|

|

|

|

|

|

|

|

|

|

| Errors |

|

|

|

|

|

|

|

|

|

|

|

Axis stopped before weld | Motion on spin or vertical |

|

| 1. | Check for obstructions to motion |

| |

axes stopped before weld | Internal machine error |

| outside welder |

| |||

end |

|

|

| ||||

| ended |

|

| 2. | Contact DUKANE service |

| |

|

|

|

|

| |||

Spin stop before weld start | Servo controller error | Internal machine error | Contact DUKANE service |

| |||

Timeout on finding vertical | Moving the vertical lower |

|

|

|

|

| |

limit up to desired position | Limit mechanism malfunctioning | Contact DUKANE service |

| ||||

lower limit position |

| ||||||

failed |

|

|

|

|

| ||

|

|

|

|

|

|

| |

|

| The torque trigger was | 1. | Torque trigger value set too | 1. | Reduce torque trigger value |

|

Timeout on torque sense | not detected within the |

| high |

| |||

| 2. | Ensure parts are properly loaded |

| ||||

|

| allowable time | 2. | Parts not loaded |

| ||

|

|

|

|

| |||

|

|

| 1. | Insufficient vacuum | 1. | Increase vacuum capability |

|

|

|

| 2. | Decrease required vacuum sensing |

| ||

Timeout on User Upper | Vacuum was not detected | 2. | Vacuum sensor threshold set |

| |||

| level |

| |||||

Part vacuum detect | within timeout |

| too high |

|

| ||

| 3. | Adjust Position (mm) value in Part |

| ||||

|

|

| 3. | Improper part pickup position |

| ||

|

|

|

| Pickup option |

| ||

|

|

|

|

|

|

| |

Timeout on vertical | Programmed weld distance | 1. | Timeout too short | 1. | Increase timeout value |

| |

distance in constant torque | not reached within the | 2. | Constant Torque maximum | 2. | Increase value of VERT.. Max (mm/s) |

| |

specified time with Constant |

| setting in Weld Parameters screen in |

| ||||

mode |

| Torque option enabled |

| vertical speed set too low |

| setup menu |

|

|

|

|

|

|

| ||

Vertical stop before starting | Vertical (press) motion |

|

| 1. | Check for obstructions to motion |

| |

stopped before spin motion | Internal machine error |

| outside welder |

| |||

spin |

| started |

|

| 2. | Contact DUKANE service |

|

|

|

|

|

| |||

|

|

|

|

| 1. | Ensure parts are loaded properly |

|

Vertical servo contact | Welder did not detect | With Part Pickup option enabled | 2. | Increase Timeout (s) value |

| ||

with Thrust Sense, part contact was | 3. | Check the Position (mm) value – it |

| ||||

sensing failed |

| programmed thrust level |

| ||||

| not detected |

| should be set slightly (<5mm) above |

| |||

|

|

|

|

| |||

|

|

|

|

|

| expected part contact |

|

|

| Weld cycle stopped | 1. | Weld process problem | 1. | Check parts to be welded, fixturing, |

|

Weld aborted by CYCLE | because cycle time |

| etc.. |

| |||

2. | Limits too narrow for weld |

|

| ||||

TIME limit |

| exceeded programmed | 2. | If practical, widen process limit |

| ||

|

| process |

| ||||

|

| process limit |

|

| window or adjust setup parameters |

| |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| Weld cycle stopped | 1. | Weld process problem | 1. | Check parts to be welded, fixturing, |

|

Weld aborted by ROTATE | because number of |

| etc.. |

| |||

2. | Limits too narrow for weld |

|

| ||||

limit |

| revolutions exceeded | 2. | If practical, widen process limit |

| ||

|

| process |

| ||||

|

| programmed process limit |

|

| window or adjust setup parameters |

| |

|

|

|

|

|

| ||

|

| Weld cycle stopped | 1. | Weld process problem | 1. | Check parts to be welded, fixturing, |

|

|

| because motor speed |

| etc.. |

| ||

Weld aborted by RPM limit | 2. | Limits too narrow for weld |

|

| |||

was outside programmed | 2. | If practical, widen process limit |

| ||||

|

|

| process |

| |||

|

| process limit |

|

| window or adjust setup parameters |

| |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| Weld cycle stopped | 1. | Weld process problem | 1. | Check parts to be welded, fixturing, |

|

Weld aborted by THRUST | because weld thrust was |

| etc.. |

| |||

2. | Limits too narrow for weld |

|

| ||||

limit |

| outside programmed | 2. | If practical, widen process limit |

| ||

|

| process |

| ||||

|

| process limits |

|

| window or adjust setup parameters |

| |

|

|

|

|

|

| ||

|

| Weld cycle stopped | 1. | Weld process problem | 1. | Check parts to be welded, fixturing, |

|

Weld aborted by TORQUE | because motor torque |

| etc.. |

| |||

2. | Limits too narrow for weld |

|

| ||||

limit |

| was outside programmed | 2. | If practical, widen process limit |

| ||

|

| process |

| ||||

|

| process limits |

|

| window or adjust setup parameters |

| |

|

|

|

|

|

| ||

Weld aborted by vertical | Vertical (press) motion |

|

|

|

|

| |

stopped before spin motion | Excessive press weld speed | Reduce press weld speed |

| ||||

servo stop |

|

| |||||

| weld was complete |

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| 1. | Weld Time, Rotations, or | 1. | Increase Weld Time, Rotations, or |

|

|

|

|

| Distance too short |

| ||

|

| Weld duration generated by |

|

| Distance above the “Min..” value |

| |

Weld duration too short | 2. | Deceleration too low |

|

| |||

programmed parameters is | NOTE: the time for deceleration is |

| indicated on the Weld Parameters |

| |||

|

| too short |

| setup screen |

| ||

|

| counted as part of the total weld |

|

| |||

|

|

| 2. | Increase spin deceleration |

| ||

|

|

| time or number of rotations |

| |||

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| Weld cycle stopped | 1. | Weld process problem | 1. | Check parts to be welded, fixturing, |

|

|

| because weld time was |

| etc.. |

| ||

Weld ended at TIME limit | 2. | Limits too narrow for weld |

|

| |||

outside programmed | 2. | If practical, widen process limit |

| ||||

|

|

| process |

| |||

|

| process limits |

|

| window or adjust setup parameters |

| |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

Page 78 | Dukane Manual Part No. |