Hydrastep Pressure Parts | General Introduction |

1.1PRINCIPLE OF OPERATION

The Hydrastep systems have been designed as electronic alternatives to conventional visual water gauges on boilers, giving more reliable and safer water level indication.

The system is based on the significant differences in resistivities of water and steam over the range 100°C (212°F) to 370°C (698°F). (Series 3

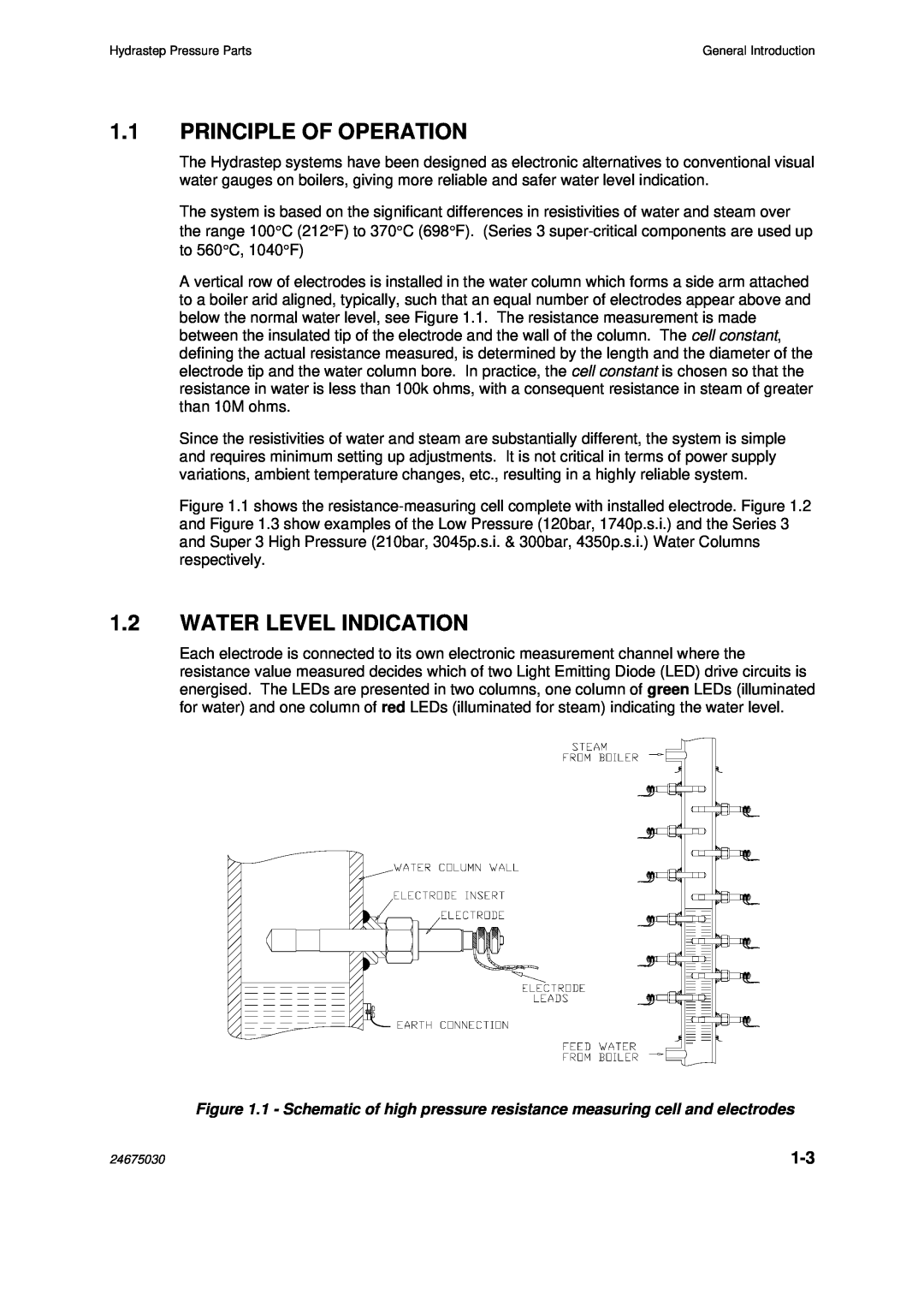

A vertical row of electrodes is installed in the water column which forms a side arm attached to a boiler arid aligned, typically, such that an equal number of electrodes appear above and below the normal water level, see Figure 1.1. The resistance measurement is made between the insulated tip of the electrode and the wall of the column. The cell constant, defining the actual resistance measured, is determined by the length and the diameter of the electrode tip and the water column bore. In practice, the cell constant is chosen so that the resistance in water is less than 100k ohms, with a consequent resistance in steam of greater than 10M ohms.

Since the resistivities of water and steam are substantially different, the system is simple and requires minimum setting up adjustments. It is not critical in terms of power supply variations, ambient temperature changes, etc., resulting in a highly reliable system.

Figure 1.1 shows the

1.2WATER LEVEL INDICATION

Each electrode is connected to its own electronic measurement channel where the resistance value measured decides which of two Light Emitting Diode (LED) drive circuits is energised. The LEDs are presented in two columns, one column of green LEDs (illuminated for water) and one column of red LEDs (illuminated for steam) indicating the water level.

Figure 1.1 - Schematic of high pressure resistance measuring cell and electrodes

24675030 |