Safety Information | Product Overview |

|

|

Installation

Diagnostics

Options and Accessories

Specification

to the logic supply are PELV, the wiring need not be isolated from direct contact within a zone of equipotential bonding, normally an enclosure or set of enclosures bonded together. Otherwise, logic wiring and circuits must be isolated from direct contact by basic insulation for 300 V system voltage.

In all applications, do not interconnect extra low voltage power supplies so that voltages add.

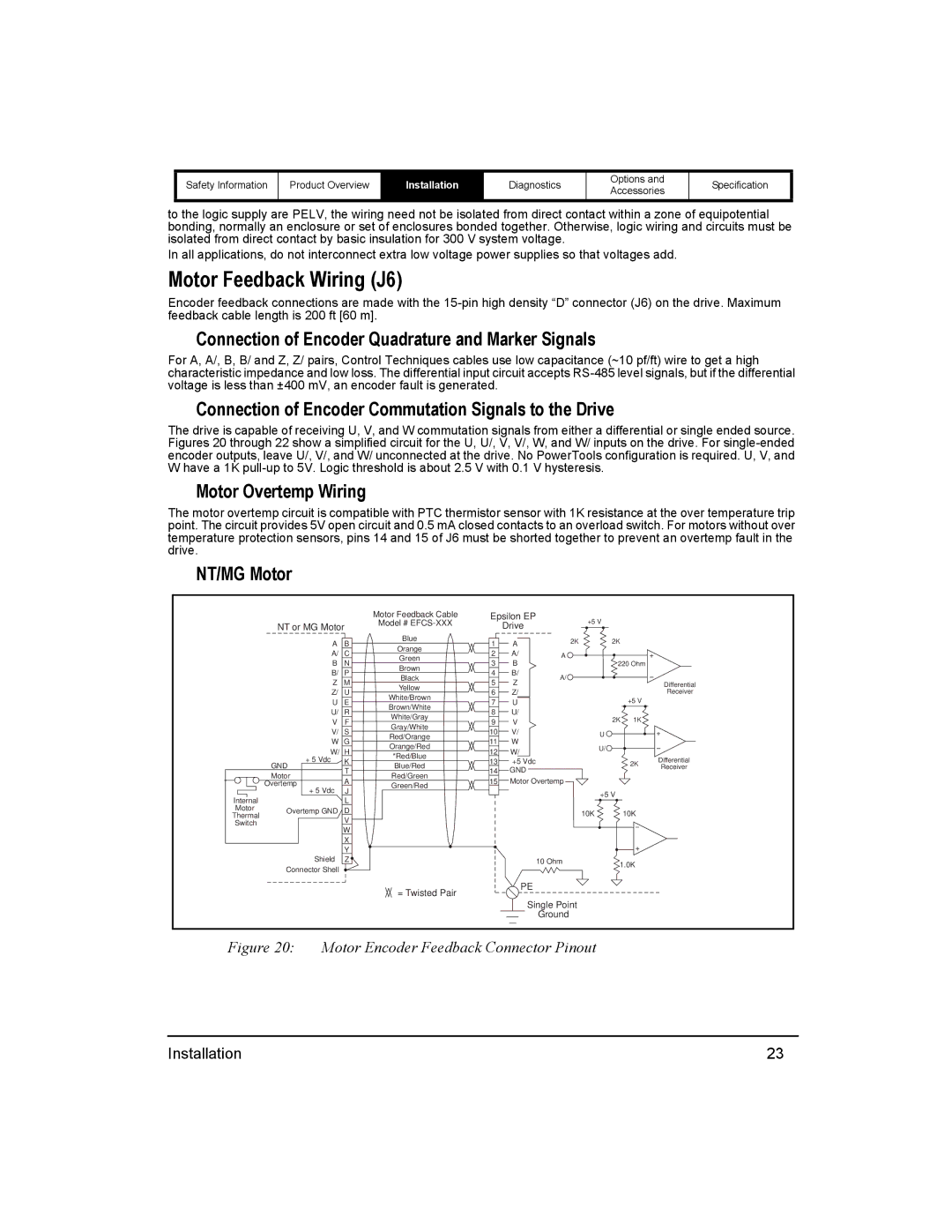

Motor Feedback Wiring (J6)

Encoder feedback connections are made with the

Connection of Encoder Quadrature and Marker Signals

For A, A/, B, B/ and Z, Z/ pairs, Control Techniques cables use low capacitance (~10 pf/ft) wire to get a high characteristic impedance and low loss. The differential input circuit accepts

Connection of Encoder Commutation Signals to the Drive

The drive is capable of receiving U, V, and W commutation signals from either a differential or single ended source. Figures 20 through 22 show a simplified circuit for the U, U/, V, V/, W, and W/ inputs on the drive. For

Motor Overtemp Wiring

The motor overtemp circuit is compatible with PTC thermistor sensor with 1K resistance at the over temperature trip point. The circuit provides 5V open circuit and 0.5 mA closed contacts to an overload switch. For motors without over temperature protection sensors, pins 14 and 15 of J6 must be shorted together to prevent an overtemp fault in the drive.

NT/MG Motor

|

|

| Motor Feedback Cable | Epsilon EP | +5 V |

|

| ||

| NT or MG Motor | Model # |

| Drive |

|

| |||

|

|

|

|

|

| ||||

| A | B | Blue | 1 | A | 2K | 2K |

|

|

| Orange |

|

| ||||||

| A/ | C | 2 | A/ | A |

|

|

| |

| Green |

|

|

| |||||

| B | N | 3 | B |

| 220 Ohm |

| ||

| Brown |

|

| ||||||

| B/ | P | 4 | B/ |

|

|

|

| |

| Black | A/ |

|

|

| ||||

| Z | M | 5 | Z |

|

| Differential | ||

| Yellow |

|

|

| |||||

| Z/ | U | 6 | Z/ |

|

|

| Receiver | |

| White/Brown |

|

| +5 V | |||||

| U | E | 7 | U |

|

|

| ||

| Brown/White |

|

|

| |||||

| U/ | R | 8 | U/ |

|

|

|

| |

| White/Gray |

| 2K | 1K |

| ||||

| V | F | 9 | V |

|

| |||

| Gray/White |

|

| ||||||

| V/ | S | 10 | V/ |

| U |

|

| |

| Red/Orange |

|

|

| |||||

| W | G | 11 | W |

|

|

| ||

| Orange/Red |

| U/ |

|

| ||||

| W/ H | 12 | W/ |

|

|

| |||

| *Red/Blue |

|

|

|

| ||||

| + 5 Vdc | K | 13 | +5 Vdc |

|

| 2K | Differential | |

| Blue/Red |

|

| ||||||

| GND | T | 14 | GND |

|

| Receiver | ||

| Motor | Red/Green |

|

|

|

| |||

| A | 15 | Motor Overtemp |

|

|

| |||

| Overtemp | Green/Red |

|

|

| ||||

| + 5 Vdc | J |

|

|

|

| +5 V |

|

|

Internal |

| L |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| ||

Motor | Overtemp GND | D |

|

|

| 10K |

| 10K |

|

Thermal |

|

|

|

|

| ||||

| V |

|

|

|

|

| |||

Switch |

|

|

|

|

|

|

|

| |

| W |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

| X |

|

|

|

|

|

|

|

| Shield | Y |

|

|

|

|

|

|

|

| Z |

|

|

| 10 Ohm | 1.0K |

| ||

| Connector Shell |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |

|

|

| = Twisted Pair |

| PE |

|

|

|

|

|

|

|

| Single Point |

|

|

| ||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| Ground |

|

|

|

Figure 20: Motor Encoder Feedback Connector Pinout

Installation | 23 |