Oxymitter 4000

Instruction Manual

IM-106-340, Rev. 4.0 May 2006

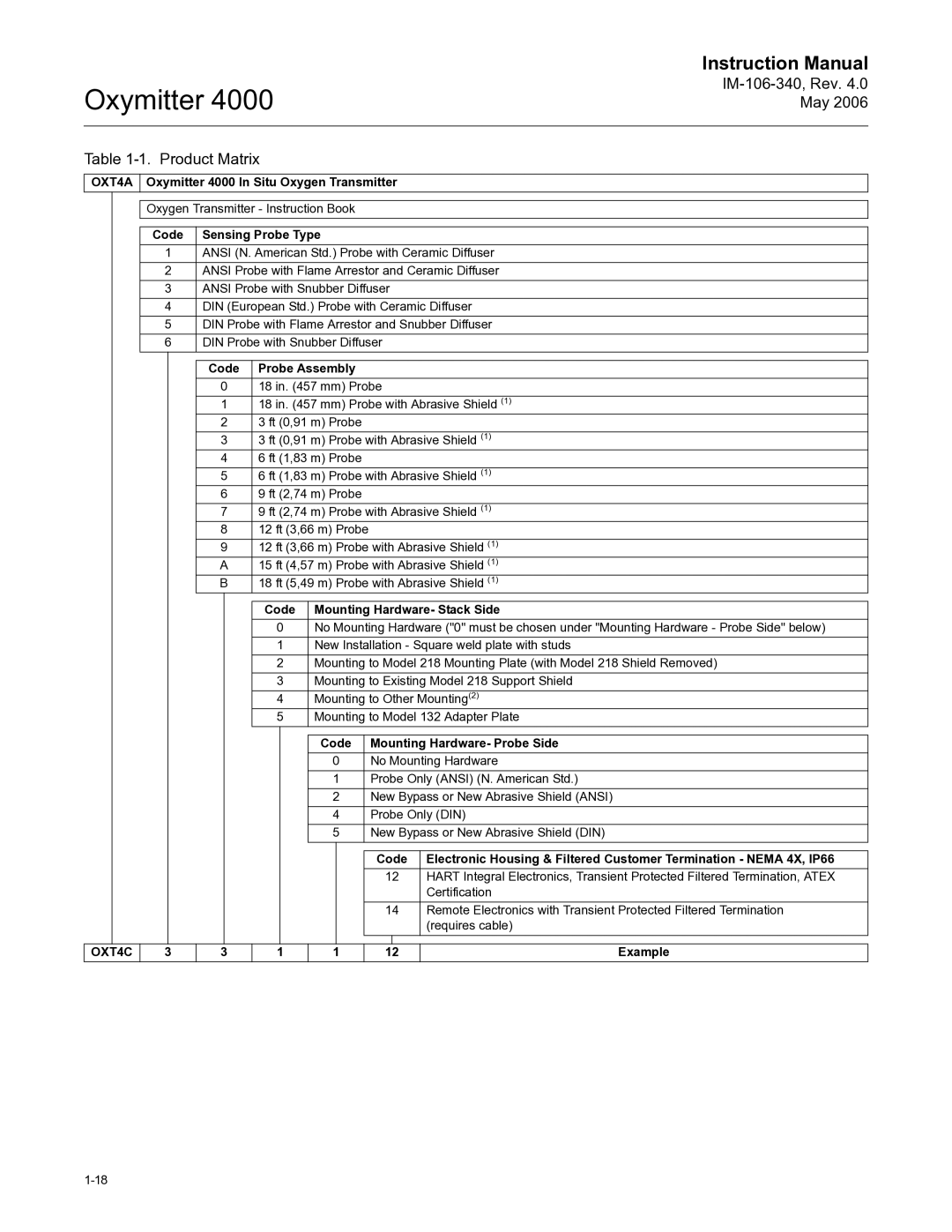

Table 1-1. Product Matrix

OXT4A

Oxymitter 4000 In Situ Oxygen Transmitter

Oxygen Transmitter - Instruction Book

Code Sensing Probe Type

1ANSI (N. American Std.) Probe with Ceramic Diffuser

2ANSI Probe with Flame Arrestor and Ceramic Diffuser

3ANSI Probe with Snubber Diffuser

4DIN (European Std.) Probe with Ceramic Diffuser

5DIN Probe with Flame Arrestor and Snubber Diffuser

6DIN Probe with Snubber Diffuser

Code Probe Assembly

018 in. (457 mm) Probe

118 in. (457 mm) Probe with Abrasive Shield (1)

23 ft (0,91 m) Probe

33 ft (0,91 m) Probe with Abrasive Shield (1)

46 ft (1,83 m) Probe

56 ft (1,83 m) Probe with Abrasive Shield (1)

69 ft (2,74 m) Probe

79 ft (2,74 m) Probe with Abrasive Shield (1)

812 ft (3,66 m) Probe

912 ft (3,66 m) Probe with Abrasive Shield (1)

A 15 ft (4,57 m) Probe with Abrasive Shield (1)

B 18 ft (5,49 m) Probe with Abrasive Shield (1)

Code | Mounting Hardware- Stack Side |

0 | No Mounting Hardware ("0" must be chosen under "Mounting Hardware - Probe Side" below) |

1 | New Installation - Square weld plate with studs |

2 | Mounting to Model 218 Mounting Plate (with Model 218 Shield Removed) |

3 | Mounting to Existing Model 218 Support Shield |

4 | Mounting to Other Mounting(2) |

5 | Mounting to Model 132 Adapter Plate |

Code Mounting Hardware- Probe Side

0No Mounting Hardware

1Probe Only (ANSI) (N. American Std.)

2New Bypass or New Abrasive Shield (ANSI)

4Probe Only (DIN)

5New Bypass or New Abrasive Shield (DIN)

Code Electronic Housing & Filtered Customer Termination - NEMA 4X, IP66

12HART Integral Electronics, Transient Protected Filtered Termination, ATEX Certification

14Remote Electronics with Transient Protected Filtered Termination (requires cable)

OXT4C

3

3

1

1

12

Example