Instruction Manual

Hazardous Area Oxymitter 4000

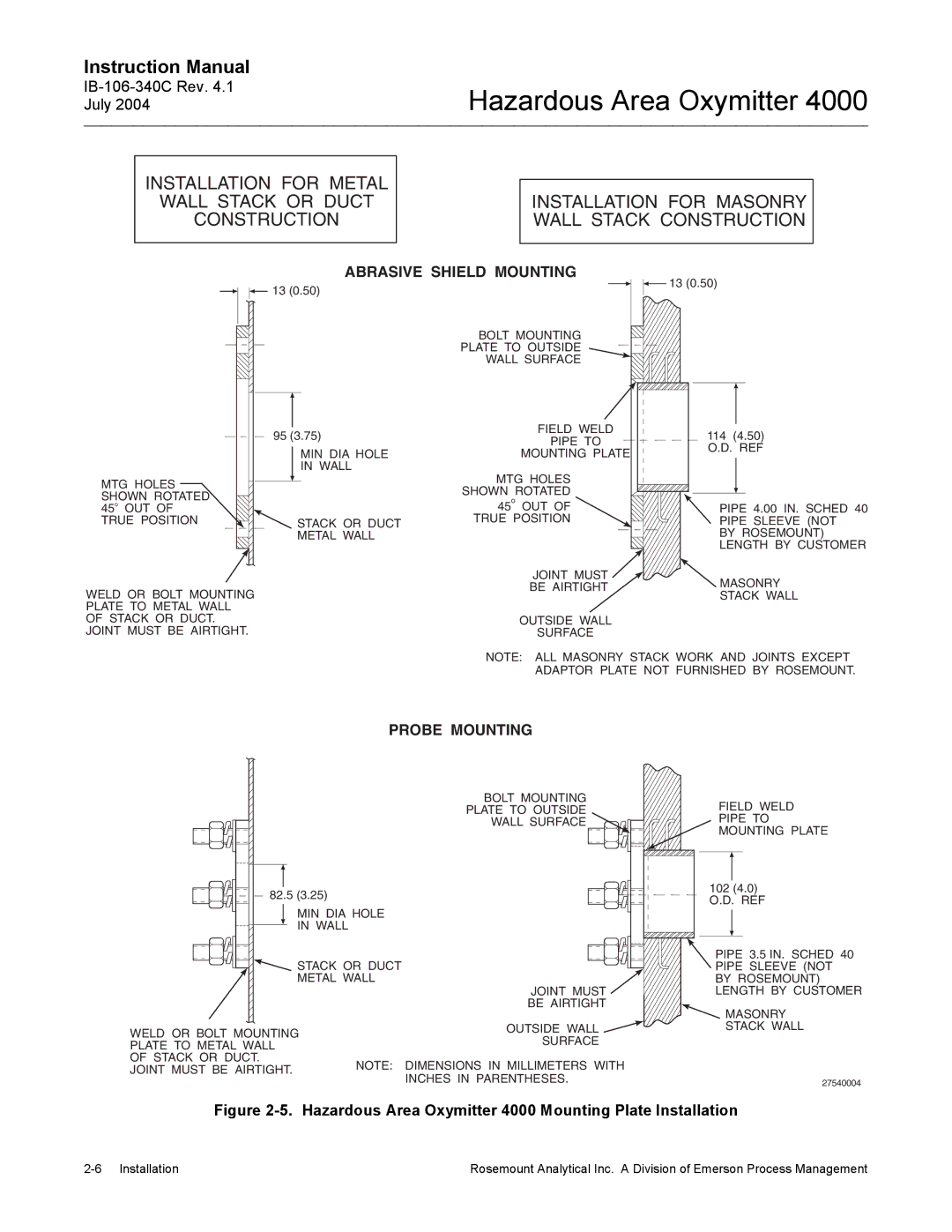

INSTALLATION FOR METAL

WALL STACK OR DUCT

CONSTRUCTION

INSTALLATION FOR MASONRY WALL STACK CONSTRUCTION

ABRASIVE SHIELD MOUNTING

| 13 (0.50) |

| 13 (0.50) |

|

|

|

|

| |

|

| BOLT MOUNTING |

|

|

|

| PLATE TO OUTSIDE |

|

|

|

| WALL SURFACE |

|

|

| 95 (3.75) | FIELD WELD | 114 | (4.50) |

| PIPE TO | |||

|

| O.D. REF | ||

| MIN DIA HOLE | MOUNTING PLATE | ||

|

|

| ||

| IN WALL |

|

|

|

MTG HOLES |

| MTG HOLES |

|

|

| SHOWN ROTATED |

|

| |

SHOWN ROTATED |

|

|

| |

| 45o OUT OF |

|

| |

45o OUT OF |

| PIPE 4.00 IN. SCHED 40 | ||

TRUE POSITION | STACK OR DUCT | TRUE POSITION | PIPE SLEEVE (NOT | |

| METAL WALL |

| BY ROSEMOUNT) | |

|

|

| LENGTH BY CUSTOMER | |

|

| JOINT MUST | MASONRY | |

WELD OR BOLT MOUNTING |

| BE AIRTIGHT | ||

| STACK WALL | |||

|

| |||

PLATE TO METAL WALL |

|

|

|

|

OF STACK OR DUCT. |

| OUTSIDE WALL |

|

|

JOINT MUST BE AIRTIGHT. |

| SURFACE |

|

|

NOTE: ALL MASONRY STACK WORK AND JOINTS EXCEPT

ADAPTOR PLATE NOT FURNISHED BY ROSEMOUNT.

PROBE MOUNTING

BOLT MOUNTING

PLATE TO OUTSIDE

WALL SURFACE

82.5 (3.25)

MIN DIA HOLE

IN WALL

STACK OR DUCT

METAL WALL

JOINT MUST

BE AIRTIGHT

WELD OR BOLT MOUNTING | OUTSIDE WALL | |

SURFACE | ||

PLATE TO METAL WALL | ||

| ||

OF STACK OR DUCT. | NOTE: DIMENSIONS IN MILLIMETERS WITH | |

JOINT MUST BE AIRTIGHT. | ||

INCHES IN PARENTHESES. | ||

|

FIELD WELD

PIPE TO

MOUNTING PLATE

102(4.0)

O.D. REF

PIPE 3.5 IN. SCHED 40 PIPE SLEEVE (NOT BY ROSEMOUNT) LENGTH BY CUSTOMER

MASONRY

STACK WALL

27540004

Figure 2-5. Hazardous Area Oxymitter 4000 Mounting Plate Installation

Rosemount Analytical Inc. A Division of Emerson Process Management |