Instruction Manual

Hazardous Area Oxymitter 4000

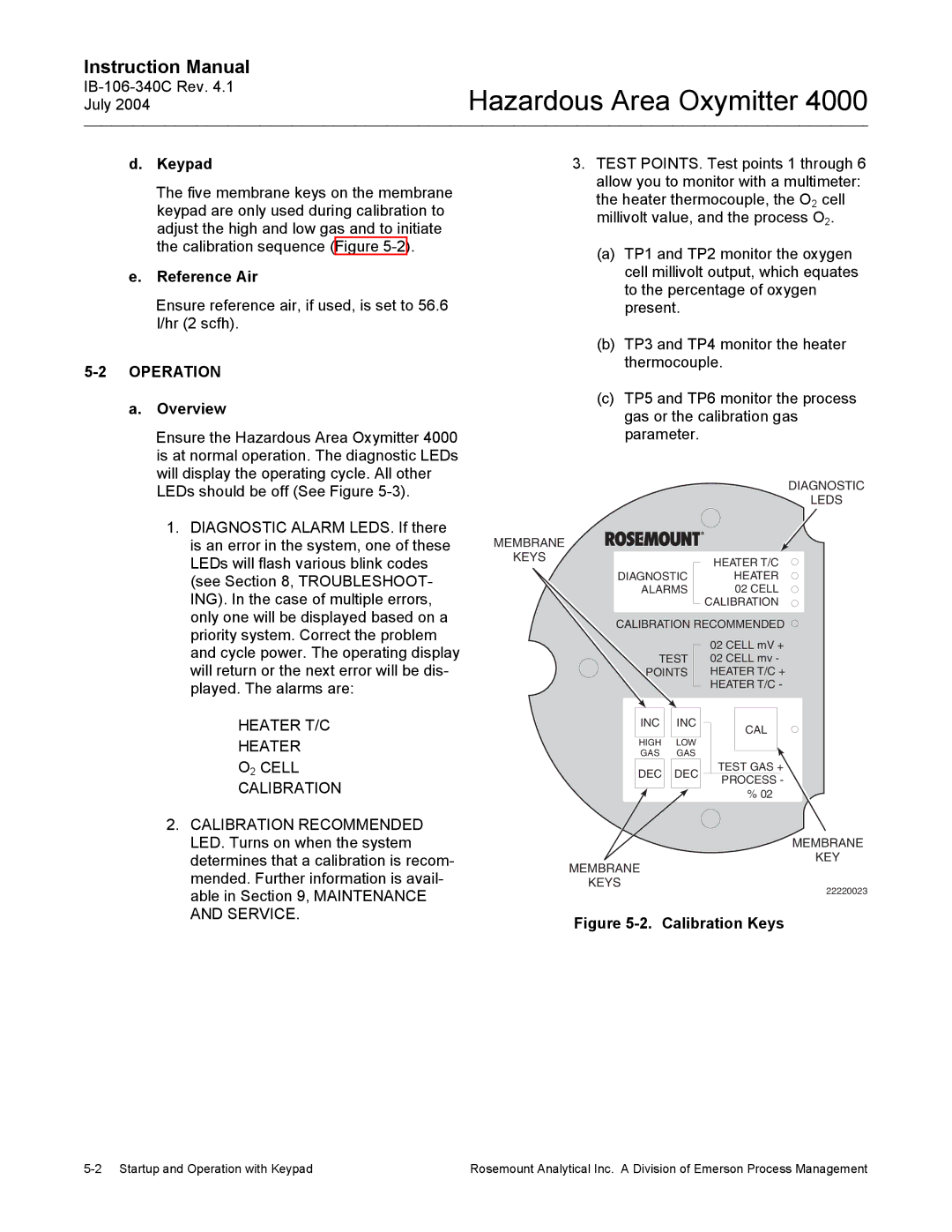

d.Keypad

The five membrane keys on the membrane keypad are only used during calibration to adjust the high and low gas and to initiate the calibration sequence (Figure

e.Reference Air

Ensure reference air, if used, is set to 56.6 l/hr (2 scfh).

5-2 OPERATION

a.Overview

Ensure the Hazardous Area Oxymitter 4000 is at normal operation. The diagnostic LEDs will display the operating cycle. All other LEDs should be off (See Figure

1.DIAGNOSTIC ALARM LEDS. If there is an error in the system, one of these LEDs will flash various blink codes (see Section 8, TROUBLESHOOT- ING). In the case of multiple errors, only one will be displayed based on a priority system. Correct the problem and cycle power. The operating display will return or the next error will be dis- played. The alarms are:

HEATER T/C

HEATER

O2 CELL

CALIBRATION

2.CALIBRATION RECOMMENDED LED. Turns on when the system determines that a calibration is recom- mended. Further information is avail- able in Section 9, MAINTENANCE AND SERVICE.

3.TEST POINTS. Test points 1 through 6 allow you to monitor with a multimeter: the heater thermocouple, the O2 cell millivolt value, and the process O2.

(a)TP1 and TP2 monitor the oxygen cell millivolt output, which equates to the percentage of oxygen present.

(b)TP3 and TP4 monitor the heater thermocouple.

(c)TP5 and TP6 monitor the process gas or the calibration gas parameter.

DIAGNOSTIC

LEDS

MEMBRANE

KEYS

HEATER T/C

DIAGNOSTIC HEATER

ALARMS 02 CELL

CALIBRATION

CALIBRATION RECOMMENDED

|

|

|

|

| 02 CELL mV + | |||

| TEST |

| 02 CELL mv - | |||||

| POINTS |

| HEATER T/C + | |||||

|

|

|

|

| HEATER T/C - | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INC |

| INC |

|

|

| CAL |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| |

| HIGH |

| LOW |

|

|

|

|

|

| GAS |

| GAS |

|

|

|

|

|

|

|

|

| TEST GAS + | ||||

| DEC |

| DEC |

|

| |||

|

|

|

|

|

|

| ||

|

|

|

| PROCESS - | ||||

|

|

|

|

|

| |||

|

|

|

| % 02 |

| |||

MEMBRANE

KEY

MEMBRANE

KEYS

22220023

Figure 5-2. Calibration Keys

Rosemount Analytical Inc. A Division of Emerson Process Management |