Hazardous Area Oxymitter 4000

Instruction Manual

July 2004

1

|

|

|

|

| Table | |

|

|

|

|

|

|

|

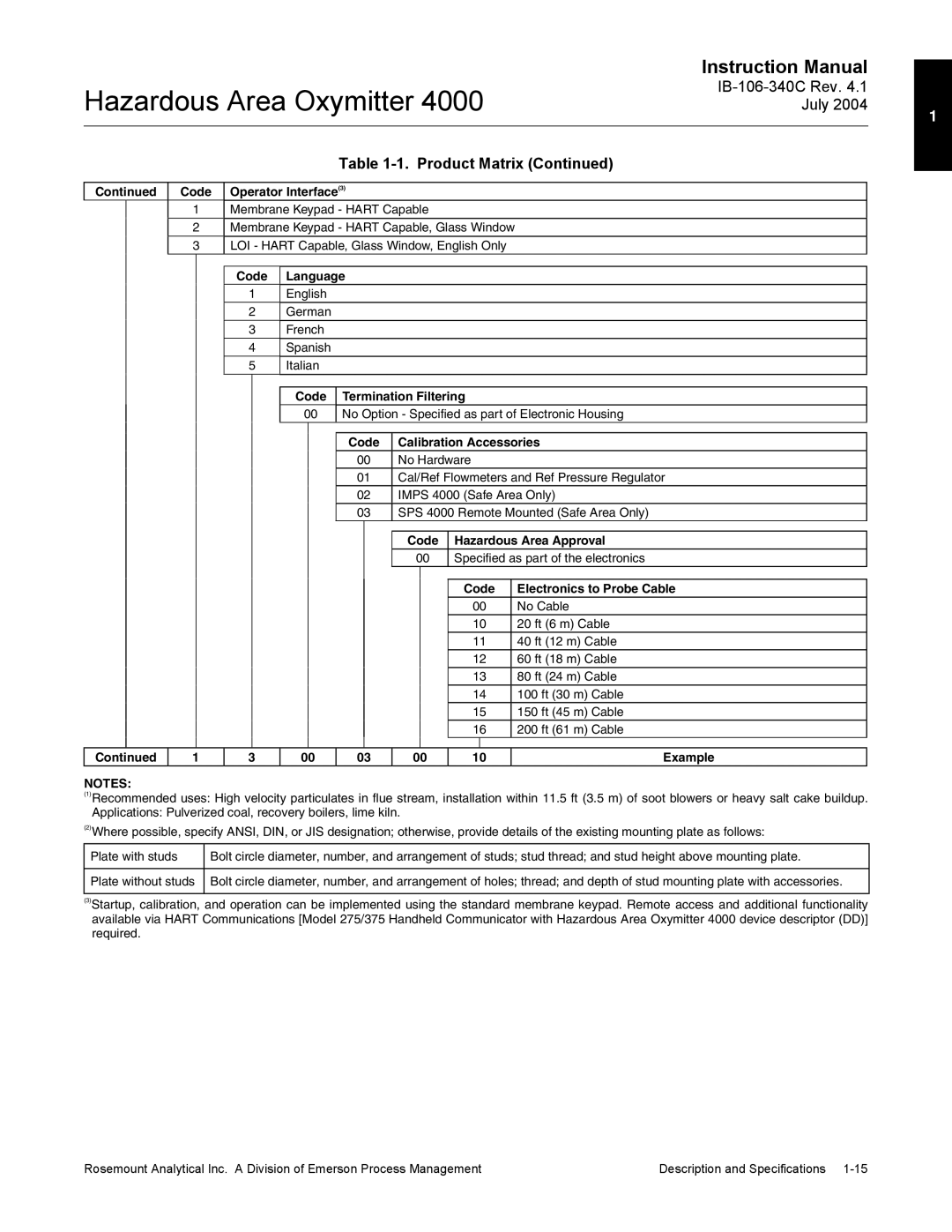

Continued | Code | Operator Interface(3) | ||||

|

| 1 | Membrane Keypad - HART Capable | |||

|

|

|

|

|

|

|

|

| 2 | Membrane Keypad - HART Capable, Glass Window | |||

|

| 3 | LOI - HART Capable, Glass Window, English Only | |||

|

|

|

|

|

|

|

|

|

|

| Code | Language |

|

1

2

3

4

5

English

German

French

Spanish

Italian

Code | Termination Filtering | |

00 | No Option - Specified as part of Electronic Housing | |

|

|

|

| Code | Calibration Accessories |

| 00 | No Hardware |

01Cal/Ref Flowmeters and Ref Pressure Regulator

02IMPS 4000 (Safe Area Only)

03SPS 4000 Remote Mounted (Safe Area Only)

Code | Hazardous Area Approval | |

00 | Specified as part of the electronics | |

|

|

|

Code Electronics to Probe Cable

00 No Cable

10 20 ft (6 m) Cable

11 40 ft (12 m) Cable

12 60 ft (18 m) Cable

13 80 ft (24 m) Cable

14 100 ft (30 m) Cable

15 150 ft (45 m) Cable

16 200 ft (61 m) Cable

|

|

|

|

|

|

|

|

|

|

Continued | 1 | 3 | 00 | 03 | 00 | 10 | Example | ||

NOTES:

(1)Recommended uses: High velocity particulates in flue stream, installation within 11.5 ft (3.5 m) of soot blowers or heavy salt cake buildup. Applications: Pulverized coal, recovery boilers, lime kiln.

(2)Where possible, specify ANSI, DIN, or JIS designation; otherwise, provide details of the existing mounting plate as follows:

Plate with studs | Bolt circle diameter, number, and arrangement of studs; stud thread; and stud height above mounting plate. |

|

|

Plate without studs | Bolt circle diameter, number, and arrangement of holes; thread; and depth of stud mounting plate with accessories. |

|

|

(3)Startup, calibration, and operation can be implemented using the standard membrane keypad. Remote access and additional functionality available via HART Communications [Model 275/375 Handheld Communicator with Hazardous Area Oxymitter 4000 device descriptor (DD)] required.

Rosemount Analytical Inc. A Division of Emerson Process Management | Description and Specifications |