Instruction Manual

Hazardous Area Oxymitter 4000

| d. | When flowing calibration gasses, the raw | work loose. Before troubleshooting the | ||||||||||||||||

|

| cell millivolt value at test points 1 and 2 | system, ensure all ICs are fully seated. | ||||||||||||||||

|

| should represent the levels on the chart in |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

| Figure | d. Electrostatic Discharge | ||||||||||||||||

|

| value increases logarithmically as the O2 | Electrostatic discharge can damage the ICs | ||||||||||||||||

|

| concentration decreases. | |||||||||||||||||

|

| used in the electronics. Before removing or | |||||||||||||||||

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

| handling the processor board or the ICs, | ||||||||||

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

| ensure you are at ground potential. | ||||||||||

| Install all protective equipment covers |

| |||||||||||||||||

|

|

| |||||||||||||||||

| and safety ground leads after trouble- |

| |||||||||||||||||

| shooting. Failure to install covers and |

| The majority of the fault conditions for the | ||||||||||||||||

| ground leads could result in serious |

| |||||||||||||||||

| injury or death. |

| Hazardous Area Oxymitter 4000 will be indi- | ||||||||||||||||

|

|

|

|

|

|

|

|

| cated by one of the four LEDs referred to as | ||||||||||

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

| diagnostic, or unit alarms on the operator’s key- | ||||||||||

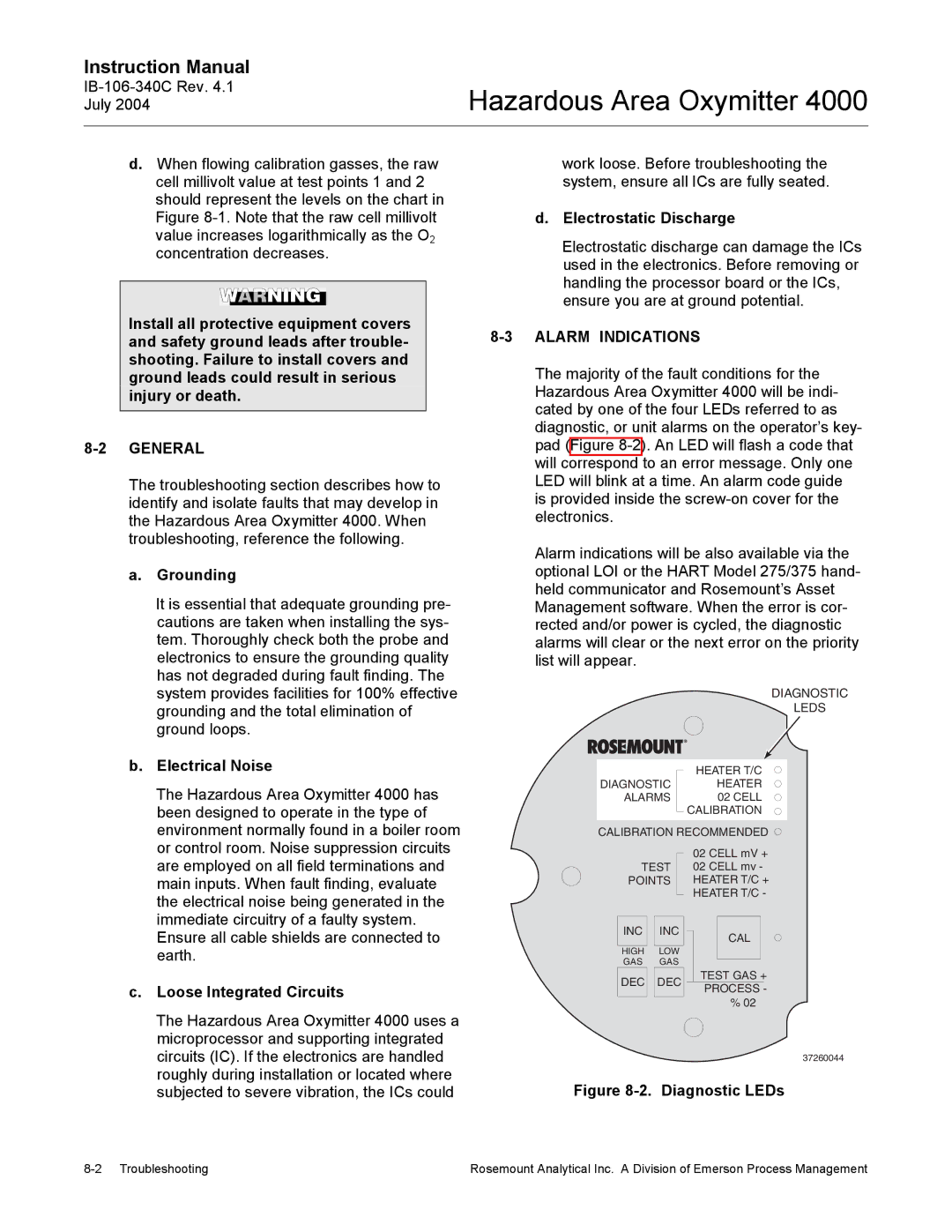

| pad (Figure | ||||||||||||||||||

|

|

|

|

|

|

|

|

| will correspond to an error message. Only one | ||||||||||

| The troubleshooting section describes how to | LED will blink at a time. An alarm code guide | |||||||||||||||||

| identify and isolate faults that may develop in | is provided inside the | |||||||||||||||||

| the Hazardous Area Oxymitter 4000. When | electronics. |

|

|

|

|

|

|

|

| |||||||||

| troubleshooting, reference the following. | Alarm indications will be also available via the | |||||||||||||||||

|

|

|

|

|

|

|

|

| |||||||||||

| a. | Grounding | optional LOI or the HART Model 275/375 hand- | ||||||||||||||||

|

| It is essential that adequate grounding pre- | held communicator and Rosemount’s Asset | ||||||||||||||||

|

| Management software. When the error is cor- | |||||||||||||||||

|

| cautions are taken when installing the sys- | rected and/or power is cycled, the diagnostic | ||||||||||||||||

|

| tem. Thoroughly check both the probe and | alarms will clear or the next error on the priority | ||||||||||||||||

|

| electronics to ensure the grounding quality | list will appear. |

|

|

|

|

|

|

|

| ||||||||

|

| has not degraded during fault finding. The |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

| system provides facilities for 100% effective |

|

|

|

|

|

|

|

|

| DIAGNOSTIC | |||||||

|

| grounding and the total elimination of |

|

|

|

|

|

|

|

|

|

| LEDS | ||||||

|

| ground loops. |

|

|

|

|

|

|

|

|

|

|

| ||||||

| b. | Electrical Noise |

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| HEATER T/C |

| ||||||||||

|

| The Hazardous Area Oxymitter 4000 has |

| DIAGNOSTIC |

|

| HEATER |

| |||||||||||

|

|

|

| ALARMS |

|

|

| 02 CELL |

| ||||||||||

|

| been designed to operate in the type of |

|

|

|

|

|

| CALIBRATION |

| |||||||||

|

| environment normally found in a boiler room |

| CALIBRATION RECOMMENDED | |||||||||||||||

|

| or control room. Noise suppression circuits |

|

|

|

|

|

| 02 CELL mV + | ||||||||||

|

| are employed on all field terminations and |

|

| TEST |

| 02 CELL mv - | ||||||||||||

|

| main inputs. When fault finding, evaluate |

|

| POINTS |

| HEATER T/C + | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

| the electrical noise being generated in the |

|

|

|

|

|

| HEATER T/C - | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

| immediate circuitry of a faulty system. |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

| INC |

| INC |

|

|

|

|

|

| |||||||

|

| Ensure all cable shields are connected to |

|

|

|

|

|

| CAL |

|

| ||||||||

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

| earth. |

|

| GAS |

| GAS |

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| HIGH |

| LOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TEST GAS + | |||

| c. | Loose Integrated Circuits |

|

| DEC |

| DEC |

|

| ||||||||||

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

| PROCESS - | |||||||||||||

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| % 02 |

|

| |||

The Hazardous Area Oxymitter 4000 uses a microprocessor and supporting integrated circuits (IC). If the electronics are handled roughly during installation or located where subjected to severe vibration, the ICs could

37260044

Figure 8-2. Diagnostic LEDs

Rosemount Analytical Inc. A Division of Emerson Process Management |