Instruction Manual

Hazardous Area Oxymitter 4000

(f)Restore power to the system; refer to paragraph

NOTE

Recalibration is required whenever electronic cards or sensing cell is replaced.

b.Replacement of Entire Electronics (with Housing) – Hazardous Area Oxymitter 4000 with Integral Electronics.

1.Follow the instructions in paragraph

Do not force the probe housing when installing or removing from the inte- gral electrical barrier/feedthrough (Figure

2. | Remove four screws (22, Figure |

| and washers (21) from the probe tube |

| assembly (23). Remove the probe tube |

| assembly from the housing (11). |

3. | Disconnect the heater and signal wire |

6.Follow the instructions in paragraph

Opening the electronic housing will cause the loss of ALL hazardous per- mits. Opening the electronics housing in hazardous areas may cause an explosion resulting in loss of property, severe personal injury, or death. It may be required to get a hot work permit from your company safety offi- cer before opening the electronic housing.

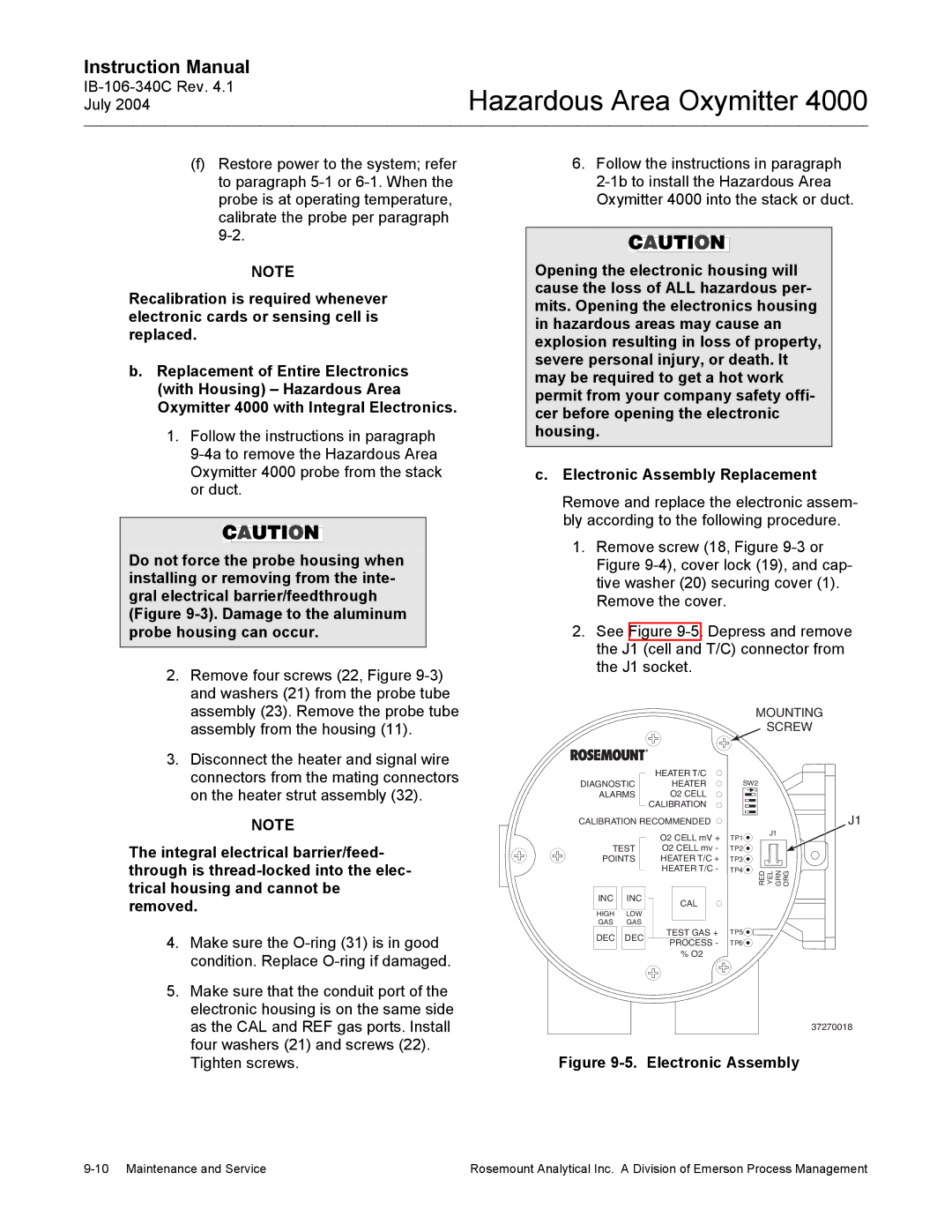

c.Electronic Assembly Replacement

Remove and replace the electronic assem- bly according to the following procedure.

1.Remove screw (18, Figure

2.See Figure

MOUNTING

SCREW

connectors from the mating connectors |

on the heater strut assembly (32). |

NOTE

HEATER T/C

DIAGNOSTIC HEATER

ALARMS O2 CELL CALIBRATION

CALIBRATION RECOMMENDED

SW2

![]() ON

ON

J1

The integral electrical barrier/feed- through is

4. | Make sure the |

| condition. Replace |

5. | Make sure that the conduit port of the |

| electronic housing is on the same side |

| as the CAL and REF gas ports. Install |

| four washers (21) and screws (22). |

TEST

POINTS

INC INC

HIGH LOW

GAS GAS

DEC DEC

O2 CELL mV +

O2 CELL mv - HEATER T/C + HEATER T/C -

CAL

TEST GAS + PROCESS - % O2

TP1 | J1 |

| |

TP2 |

|

TP3 |

|

TP4 | RED YEL GRN ORG |

| |

TP5 |

|

TP6 |

|

37270018

Tighten screws. |

Figure 9-5. Electronic Assembly

Rosemount Analytical Inc. A Division of Emerson Process Management |