Appendix

Since the composition and quality of special paper vary considerably, special paper is more likely than white bond paper to give trouble during printing. No liability will be assumed if moisture and so forth given off during printing on special paper causes harm to the machine or operator.

NOTE: Before purchasing any type of special paper, test a sample on the machine and check that printing quality is satisfactory.

Transparency

Transparency must be able to withstand the heat of fusing during the printing process. It should satisfy the conditions in the table below.

Item | Specification |

|

|

Tolerance of heat | Must tolerate at least 190°C (374°F) |

|

|

Thickness | 0.100 to 0.110 mm (3.9 to 4.3 mils) |

|

|

Material | Polyester |

|

|

Dimensional accuracy | ±0.7 mm (±0.0276 in) |

|

|

Squareness of corners | 90° ±0.2° |

|

|

To avoid problems, feed transparencies from the

If transparency jams frequently, pull the top of the sheet very gently as it leaves the machine.

Labels

Labels must be fed from the

The basic rule for printing on adhesive labels is that the adhesive must never come into contact with any part of the machine. Adhesive paper sticking to the drum or rollers will damage the machine.

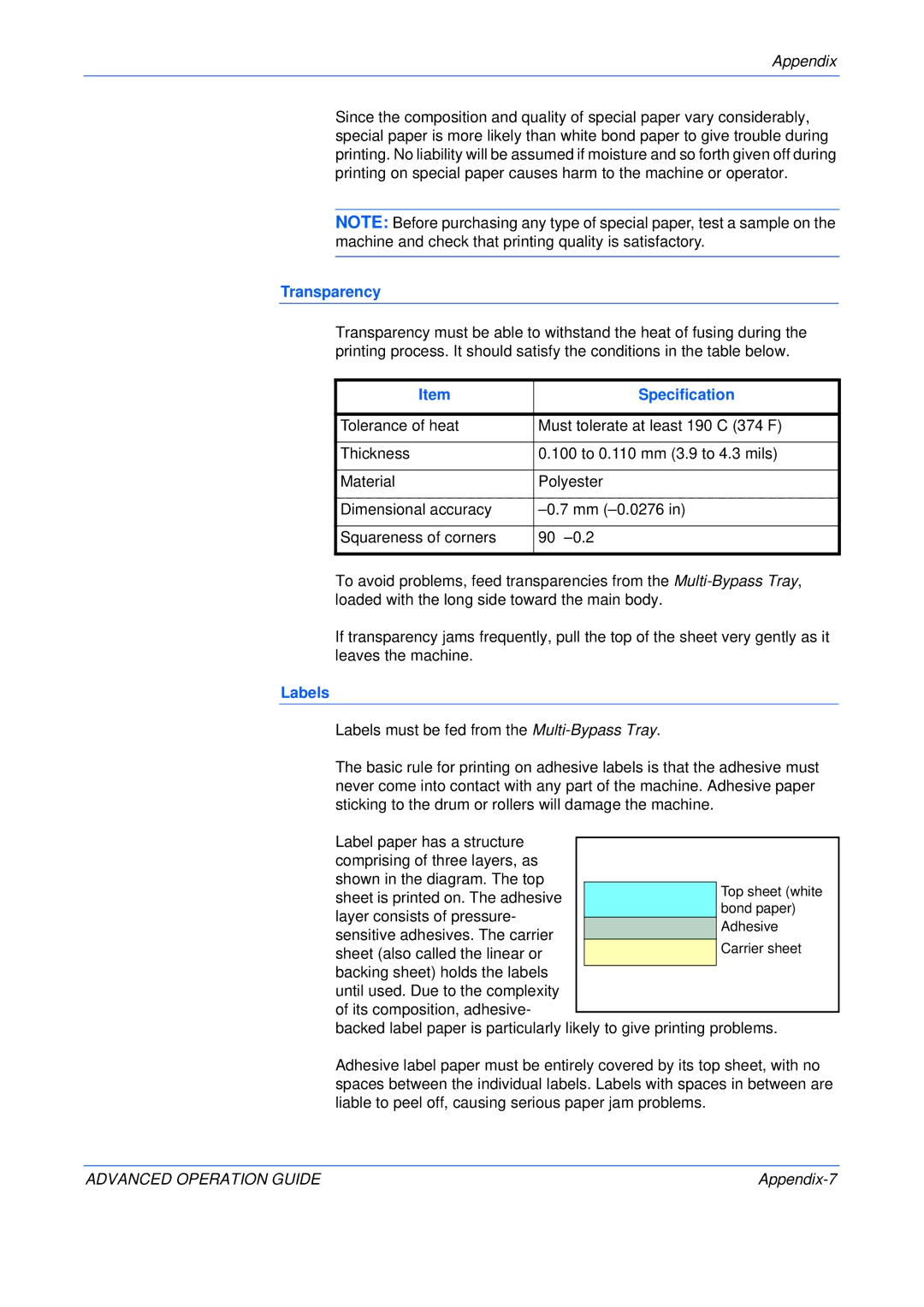

Label paper has a structure comprising of three layers, as shown in the diagram. The top sheet is printed on. The adhesive layer consists of pressure- sensitive adhesives. The carrier sheet (also called the linear or backing sheet) holds the labels until used. Due to the complexity of its composition, adhesive-

backed label paper is particularly likely to give printing problems.

Adhesive label paper must be entirely covered by its top sheet, with no spaces between the individual labels. Labels with spaces in between are liable to peel off, causing serious paper jam problems.

ADVANCED OPERATION GUIDE |