Epson Stylus Scan

Epson Stylus Scan Revision a

Precautions

Preface

Revision Status

Issued Date

Revision

Description

Epson Stylus Scan Revision a

Contents

Maintenance

Product Description

Mode Scan Output Print Micro Dot Size Head Media

Local Copy Specifications

Mode Res Weave

Local copy

Document

Scan area

Starting scan Edge Position 1st bit Scanning Area

Document

Paper feed direction Printable Area

Print area

Print Area

Printing

Raster Graphics mode

Input data buffer

Control codes

Printable Area for Envelopes

Paper

Envelope Margin

Size Left Margin Right Margin Top Margin Bottom Margin Min

Color Ink Cartridge

9 Ink

AAS

Scanner

Common

Safety, EMC Electrical specifications

Environmental conditions

Humidity % Temperature C

Resistance to electric noise

Reliability

Parallel

Interfaces

Printer Interface

USB Preventing Data Transfer TIME-OUT of Hosts

USB Configuration

Interface Selection

Pin #2 Pin #1

IEEE1284.4 Protocol

Scanner interfaces

Element Description

Scanner Configuration for USB

USB

11. Special settings mode

10. Power-on functions

Control Panel

Buttons

12. Copy button functions

Copy Button

100% B&W Normal Quality Reduce Button Enlarge Number Color

Warm up

LCD

13. Settings Menu

14. LCD display and LED indicators

Indicators and LCD Display

15. Initialization

Initialization

Printer Initialization

Scanner Initialization

Settings Menu

16. Settings Menu

PRINTER-SPECIFIC Errors

Stylus Scan Errors

17. Printer-SPECIFIC errors

Menus

Options

SCANNER-SPECIFIC Errors

Scanning

ADF

Weight

Physical Characteristics

Dimensions

Page

Operating Principles

Printer Mechanism Operation

General

Motor Types and Corresponding Functions

Motor Type Function For details

PF motor

Printing Mechanism

Pump unit

CR guide shaft CR Motor PF roller PG lever

Sensor

Nozzle selector Board

Ink cartridge

Piezo unit Filter

Normal State

Printing Process

Ink course Piezo unit Cavity Ejecting State

Nozzles

CR Motor Control for Each Mode

Carriage Motor Specifications

Phase drive

Carriage Mechanism and Motor

Motor

Platen GAP Lever

Unit Forward

Normal

Paper Feeding Mechanism

Motor Control for Each Mode PF Motor Specifications

Paper Feeding Mechanism Top View

Multiple Paper Loading Prevention Mechanism right side view

MULTI-FEED Prevention Mechanism

Method

Smaller TRAILING-EDGE Margin

Power on sequence

Power off sequence

Carriage Lock Mechanism

Paper eject sequence

Combination 12.4,28 Eject roller transmission Gear

Paper PICK-UP Operation

Carriage lock Lever Cleaner blade

Pump, Carriage Lock, Head Cleaner Mechanism

Ink System

Pump roller Cap unit

Gear B Compression Spring Gear C Pump drive Roller

Pump Motor Rotation and Function

Pumping modes

Pump Mode Revolutions Absorption

Cap Mechanism

Carriage Unit

Scanner Principles

20. Carriage Movement

Carriage Operation

Local copy process

Local and PC Copy Principles

Stylus Scan 2500 Local Copy

Dpi Type Removal

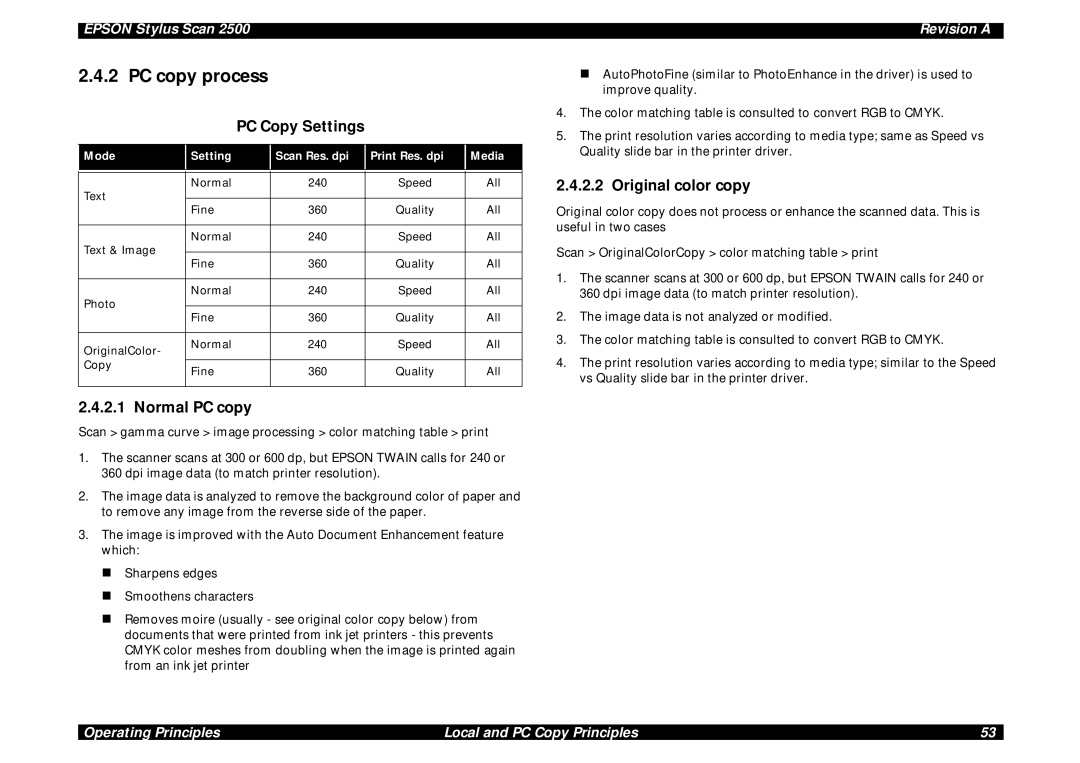

Mode Setting Scan Res. dpi Print Res. dpi Media

PC Copy Settings

PC copy process

Normal PC copy

Electrical Circuit Operating Principles

Voltage Application Printer Scanner

1 B102 PSB/PSE Board

Application of DC Voltage

ZD53 Switch

Power signal

D89 D51 C51,C52 Power drop

Circuit Switch

2 B102 Main Board

Option

1284 I/F

Transceiver

Unit

Epson Stylus Scan Revision a

Troubleshooting

Printer Condition and Panel Stat us

Unit Level Troubleshooting

Flowchart

Printer/Scanner does not operate at power on

Symptoms and Problem s

EndEnd

Error is detected

Failure occurs during printing

Control panel operation is abnormal

Printer does not feed paper correctly

Printer-Specific errors

Printer Related Troubleshooting

Repair of the Printer Mechanis m

Symptom Condition Cause Check Point Solution

Repair of the Printer Mechanism

Epson Stylus Scan Revision a

Epson Stylus Scan Revision a

User-level Scanner-Specific errors

Scanner Troubleshooting

Service Level Troubleshooting Starts Here

Power problems

Carriage Unit does not operate

Scanner does not initialize

11. The lamp does not light up

10. Carriage unit crashes into frame

14. Parallel Interface Error

13. Scsi Interface Error

12. Poor image quality

15. Option unit malfunction

16. Motor Resistance and Measurement Procedure

Troubleshooting Motors and Sensors

Sensor Name Location Signal Level Sensor Status

17. Sensor Check

Disassembly & Assembly

Overview

Assembling or adjusting the printer

When transporting the printer after installing

Make the specified adjustments when you

When assembling, if an ink cartridge is removed

Screw Characteristics

Specification for Screws

Tools

Tool List

Head Top Side Body Washer Assembled

Screw Types and Abbreviations

Category Component Item to check Is Check Required?

Service Checks After Repair

Inspection Checklist for the Stylus Scan

Epson Stylus Scan Revision a

Disassembly Procedures

Removing the rear cover

Removing the Housing

Remove three CBS 3x6 screws

Removing the control panel assembly

Removing the top cover

Removing the scanner support frame

Removing the side covers

Removing the paper eject assembly

Remove two screws On the left side

Removing the power supply board upper frame

Cable protector Remove two Screws

Removal of the B102 PSB/PSE Board

Removing the printer mechanism

Remove three screws Remove two screws Remove one screw

Remove four screws

Removal of the Circuit Board Tray

Removal of the Printer Consumables

Spacer Waste ink tank

Removing the waste ink pads

Removing the cleaning assembly Pump Cap

Assembly, be careful that the parts do not pop out during

When reassembling the cleaning assembly, refer to

Disassembly and assembly

When assembling the printer, be careful not to crush nor

Removing the Cap and Pump Assemblies

Removing the Printhead Unit

Disassembling the Printer Mechanism

Nozzle Selector has been enclosed into head

Fastener Head

Compression Spring

Removing the PF Motor Assembly

No.1

Removing the CR Motor Assembly

Removing the ASF Assembly

Removing the ASF Assembly

Disassembling the ASF Roller Assembly

Paper Feed Roller Assembly

Hopper Assembly Brake Leveer Torsion Spring

Epson standard color

Black

When installing the LD roller assembly, make sure

Removing the Right and Left LD Roller Assembly

Assembly

That the hooks are hung on the paper feed

Removing the Carriage Assembly

12. Removing the Carriage Assembly

Removing the PF Roller Assembly

PF Roller Assembly

Front Paper Guide B Eject Paper Roller Assembly

16. Removing the PE Detector Assembly

Removing the PE Paper Detector Assembly

HP Detector

Disassembly of the Scanner Mechanism

Removing the HP Detector

Remove two screws

Removing the scanner

Removing the lamp

Remove spring here Remove the FFC

Removing the scanner power supply board

Removing the scanner assembly from the scanner guide shaft

Frame as described in .7.1.3 above

Removing the scanner motor

Adjustment

List of Service Procedures That Require Adjustment

Required Adjustments

List of Required Adjustments

Content of Operation Adjustment Procedure

Adjustment Tools Required

Printer Adjustment

Printer hardware adjustments

Parallelism Adjustment

Checking Parallelism

Left Parallelism Adjustment

Fixing Parallelism Adjustment Bushing

Installing the program

Using the Service-Adjustment Program

Service Menu Items

Software-based Adjustment Procedures

Openning the Start-up menu

Head ID Menu

Adjustment Using the Service-Adjustment Program 118

Adjustment Using the Service-Adjustment Program 119

Production Menu

Adjustment Using the Service-Adjustment Program 121

Initial Ink Charge Operation

Bi-D Adjustment

CL2 cleaning operation takes 60 seconds to complete

Head Cleaning Operation

Following patterns are printed

Head Angular Adjustment

Head Voltage ID Input

Printhead Securing screw

Sample of Head Angular Adjustment Pattern

Special Menu

Scanner Adjustment

Ink draining

Maintenance

Lubrication

Cleaning

Printer lubrication points

Scanner lubrication points

Standard Remarks Pag

Lubrication Point s

Maintenance Overview 131

Maintenance Overview 132

GEAR,8

Gear 40.8 No.4

Two Pieces

Roller, Exit

Maintenance Overview 135

Oil pad Lubricated side

Faces out Carriage Assembly Bottom view

Never apply the oil exceeding 0.6cc

GEAR,8 No.6 No.7

No.3 Gear

No.9

No.10 No.8

Scanner Mechanism

Type Name Supply Specification Quantity

Appendix

Connector

Board Connector Summary

Connector Pin Assignment

Connector Pin Assignment-CN9

Connector Pin Assignment-CN8

Connector Pin Assignment-CN10

10. Connector Pin Assignment-CN11

12. Connector Pin Assignment-CN13

11. Connector Pin Assignment-CN12

13. Connector Pin Assignment-CN1

14. Connector Pin Assignment-CN15

Settings

Address Explanation Setting

Eeprom Address Map

15. Printer Unit Eeprom Address Map

Appendix Eeprom Address Map 147

Appendix Eeprom Address Map 148

16. System Unit Eeprom Map

Appendix Eeprom Address Map 150

Appendix Eeprom Address Map 151

Appendix Exploded Diagrams 152

Exploded Diagrams

Epson Stylus Scan 2500 No.1

Epson Stylus Scan 2500 No.2

Epson Stylus Scan 2500 No.3

Epson Stylus Scan 2500 No.4

Epson Stylus Scan 2500 No.5

Epson Stylus Scan 2500 No.6 Rev.01

Epson Stylus Scan 2500 No.7

Epson Stylus Scan 2500 No.8

Packing Material for Epson Stylus Scan

RefernceNumber Part Name

Parts List

17. Parts List

Appendix Parts List 163

Appendix Parts List 164

Appendix Parts List 165

Appendix Parts List 166

Component Layouts

Appendix Component Layouts 168

Appendix Component Layouts 169

Appendix Component Layouts 170

Appendix Component Layouts 171

Circuit Diagrams

Page

Page

Page