ProMix PD2K Proportioner for Automatic Spray Applications

Important Safety Instructions

Contents

Manual No Description

Related Manuals

Manual No

ECB Labels

Models

0359

Model AC2000 High Pressure Identification Label

Fire and Explosion Hazard

Intrinsic Safety

Personal Protective Equipment

Moisture Sensitivity of Isocyanates

Important Isocyanate ISO Information

Isocyanate Conditions

Keep Components a and B Separate

General Information

Advanced Display Module ADM

USB Download Procedure

ADM Display

USB Upload Procedure

ADM Keys and Indicators Function

ADM Keys and Indicators

Soft Key Functions

Soft Key Icons

Key Function

Key Function

Screen Icons

Navigating the Screens

Power On

Pre-operation Checklist

Pre-Operation Tasks

Flush Before Using Equipment

Initial System Setup

Valve Settings

With Color Change

Without Color Change

Prime and Fill the System

Operation Using Automatic Display Module ADM

Spraying

Flush Mixed Material

Purging

Color Change System

Shutdown

Flush the System

Single Color System

PD2K Discrete I/O Connections

Operation Using a Programmable Logic Controller PLC

Network Communications and Discrete I/O

Discrete I/O

Analog Inputs

Digital Inputs

KEY

Discrete I/O Connections on Efcm

CGM Overview

Communication Gateway Module CGM Details

CGM Kits

ProMix PD2K Network Outputs

Output Register 00 Current System Mode

Number Operation Mode Description

Network Communication I/O Data Map

Output Register 06 Actual Mix Ratio

Output Registers 01, 02, 03, and 04 Pump Status

Pump States for Output Registers Description Ber

Output Register 05 Actual Mix Flow

Output Register 12 Active Recipe Material B Flush Sequence

Output Register 14 Active Recipe Potlife Timeout Set Point

Output Register 27 Safety Interlock Input Status

Output Registers 28 36 DCS Command Structure

Output Register 38 40 Software Version

Output Register 37 Time

Operation Using a Programmable Logic Controller PLC

None

Network Output Data Map Read Only

PSI

= ERR

= Busy

= ACK

= NAK

ProMix PD2K Network Inputs

Input Register 00 System Mode Command

Input Register 03 Mix Pump 1 Control Set Point

Input Register 02 Flush/Prime Pump Command

Input Register 07 Go to Recipe Number

Input Register 10 Gun 1 Trigger

Input Register 08 Clear Active Alarm

Input Registers 14 21 DCS Command Structure

Input Register 09 Job Complete

Operation Using a Programmable Logic Controller PLC

Network Input Data Map Write/Read

40180 Gun 3 Trigger Uint32

Purge Mode Sequence

Operation Flow Charts

Inactive Pump Flush and Prime Sequences

Flush Pump Command

Change

Color Change Sequence

Standby Mix Ready? no

Mixing Sequence

Clear Active Alarm

Alarm Clearing Sequence

Dynamic Command Description

Network Communication Dynamic Command Structure DCS

DCS

List of DCS Commands

Dynamic Commands with Command ID

Write User ID

Write Recipe

Write Flush Sequence

Read User ID

Write Fluid Control Mode

Read Flush Sequence

Read Recipe

Read Fluid Control Mode

Yymmdd

Read Job Info

Yymmdddw

Read Alarm Info

Example Ascii Character String Decode Algorithm

Read Event Info

Flow Control System

Opening Screen

Run Mode Screens

Home Screen

See Advanced Screen 1, page 82, to set

Home Screen Key Description Details

Key Description

Key Description

Spray Screen

Spray Screen, in Standby Mode

Fill Screen, Color a Selected

Fill Screen

Usage Screen

Usage Screen

Jobs Screen

Errors Screen

Events Screen

Password Screen

Setup Mode Screens

System Screen

Mix Pressure Tolerance

Mix Idle Timeout

Mix No Flow Timeout

Low Flow Timeout

Hose Length and Diameter

Gun Hose Length

Gun Hose Diameter

Mix At Wall

Gateway ID

Enable

Manual Override

Gun Trigger Signal

Flow Control Setpoint Signal

Fluid Control

Recipe Screen

Flush Screen

Pump Screen

Default Settings Not Selected

Default Settings Selected

Pump Screen 3, Pressure Monitoring Disabled

Pressure Alarm and Deviation Limits

Calibrate Screen

Calibration Screens

Volume Check Screen

Enter Measured Volume of Solvent

Maintenance Screen

Maintenance Screens

Maintenance Screen 4, Color Valve Resets

Advanced Screen

Download Depth

Enable USB Downloads/Uploads

Log 90% Full Advisory Enabled

Display Units

Pump Pressure Check

Calibration Checks

Perform the pressure check

Pump Volume Check

Scroll to Calibrate Screen 3,

Solvent Meter Calibration

Single Color Systems

Color Change

Multiple Color Systems

To Clear Error and Restart

System Errors

Gun Trigger Input Function

Purge Errors Code Type Description Problem Cause Solution

Error Codes

Mix Errors Code Type Description Problem Cause Solution

Pumping Errors Code Type Description Problem Cause Solution

EBH#

Code Type Description Problem Cause Solution

SAD1

Pressure Errors Code Type Description Problem Cause Solution

Qbdx

Qadx

CAC#

System Errors Code Type Description Problem Cause Solution

Emix

CA0X

CDC#

Cagx

Cddx

USB Errors Code Type Description Problem Cause Solution

USB

Wxud

Wxuu

B9BX

B9AX

B9SX

ENT#

Calibration Errors Code Type Name Description

END#

ENS0

Code Type Name Description

Maintenance Errors

Flushing

Maintenance

Preventive Maintenance Schedule

Cleaning the ADM

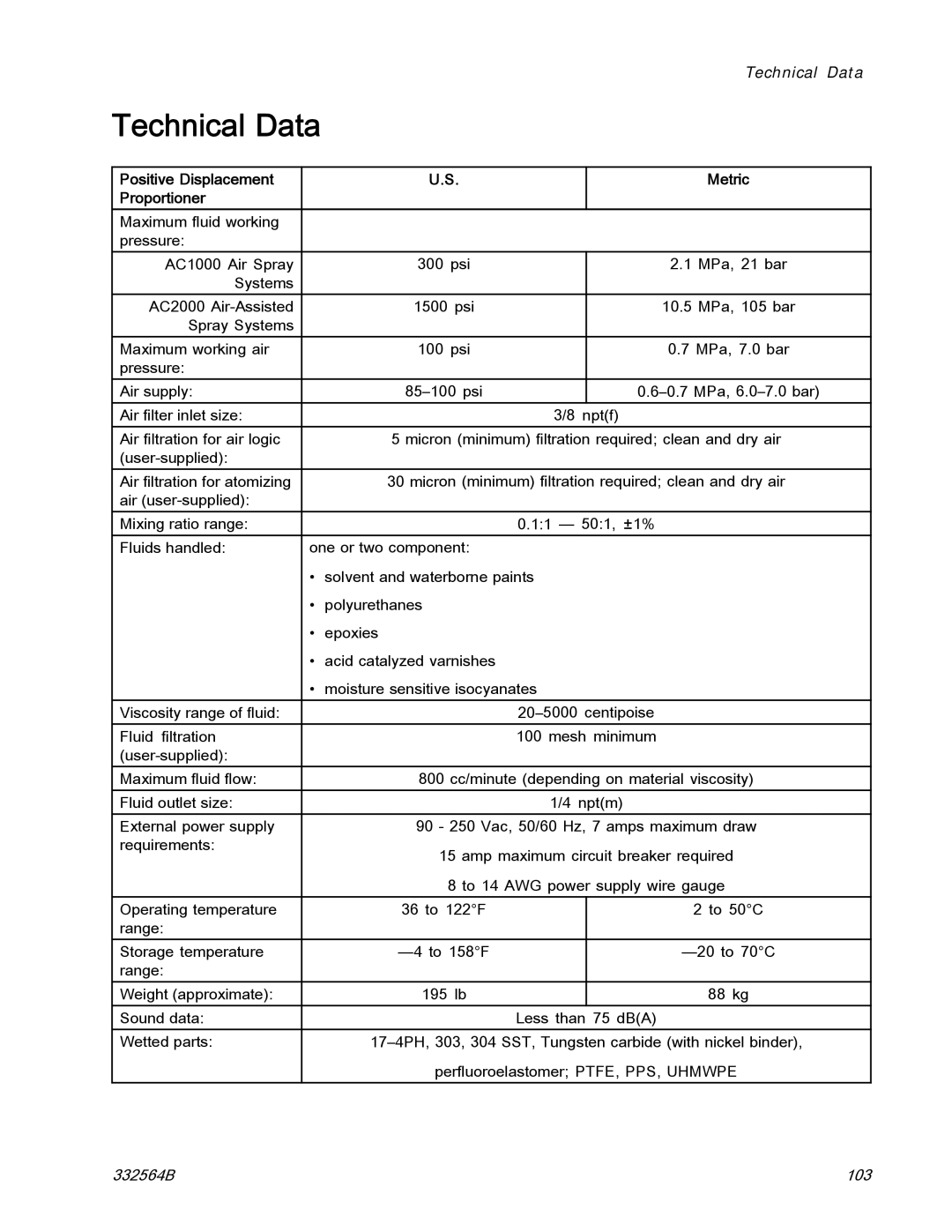

Positive Displacement Metric Proportioner

Technical Data

Graco Information

Graco Standard Warranty

For Graco Canada Customers