Pre-Operation Tasks

Pre-operation Checklist

Go through the

✔Checklist System grounded

Verify all grounding connections were made. See Grounding in the Installation manual.

All connections tight and correct

Verify all electrical, fluid, air, and system connections are tight and installed according to the Installation manual.

Fluid supply containers filled

Check component A and B and solvent supply containers.

Dose valves set

Check that dose valves are set

Fluid supply valves open and pressure set

The recommended component A and B fluid supply pressures are 1/2 to 2/3 of the target spray pressure.

NOTE: Low pressure systems may be set within a range of ± 100 psi (0.7 MPa, 7 bar); high pressure systems may be set within a range of ± 300 psi (2.1 MPa, 21 bar). If the inlet pressure is higher than the outlet pressure, ratio accuracy may be affected.

Solenoid pressure set

Power On

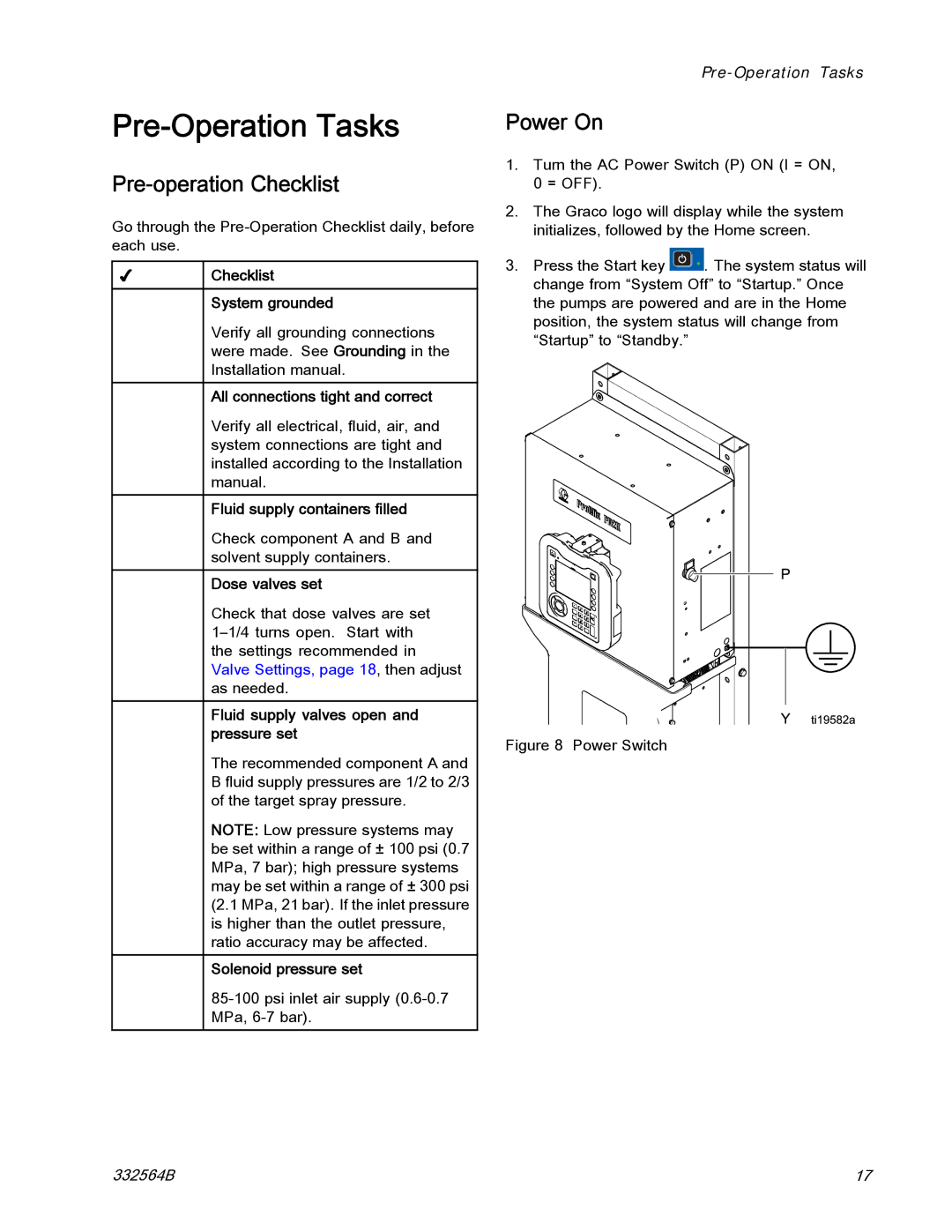

1.Turn the AC Power Switch (P) ON (I = ON, 0 = OFF).

2.The Graco logo will display while the system initializes, followed by the Home screen.

3.Press the Start key ![]() . The system status will change from “System Off” to “Startup.” Once the pumps are powered and are in the Home position, the system status will change from “Startup” to “Standby.”

. The system status will change from “System Off” to “Startup.” Once the pumps are powered and are in the Home position, the system status will change from “Startup” to “Standby.”

Figure 8 Power Switch

332564B | 17 |