EN1I-6187 Issue 5 12/01

DCP552 Mark ΙΙ Digital Control Programmer User’s Manual

Warranty

Unpacking

Configuration of This User’s Manual

Contents

Event Output Open Collector Output Connection

Mode transitions

PID group selection

Program Setup

Parameter Setup

Operation

Troubleshooting

Memory Card Operations

Specifications

Calibration

Program Work Sheet Parameter Work Sheet

Index

Handling Precautions

Conventions Used in This Manual

Disp key, ↑ key

FUNC+PROG key

Features

Basic Function Block Diagram

RUN Hold Reset

Total of 49 patterns

Data Configuration Overview

Parameters

System Configuration

CPL communications network-based configuration

Model Number

Model number DCP552E2

Names and Functions of Parts

Structure

Basic display status

Console

Display

MAN

Key pad

Enter key Enter key

# $%

Key chord functions

Func + →

Display channel select key

Loader jack

↑ + Prog

Resistance temperature detector

Input Type and Range Number

Input

Thermocouple

DC current, DC voltage

Before Installation

Mounting position

Sources of electrical interference and countermeasures

Dust proof cover

Installation

Panel cutout dimension

Installation procedures

Handling Precautions

Wiring

Precautions on Wiring

Wiring

Recommended Cables

Making Terminal Connections

Terminal Array

11 do

Power Supply and Grounding

Power supply

Grounding

Model No

PV input CH1 connection

PV Input Analog Input Connection

PV input CH2 connection

Handling Precautions

Control Output Connection

Open

Auxiliary Output Connection

Auxiliary output CH1 connection

Event Output Open Collector Output Connection

EV1 EV2 EV3 EV4 EV5 EV6 EV7 EV8

External Switch Input Connection

Communication Connection

RS-485 connection

Wire system RS-485 connection diagram

RDA RDB SDA SDB

Terminating resistor Master station

RS-232C connection

Connection to ST221

Isolation Between Input and Output

Data

Data types

Pattern

Program Pattern

RAMP-X system

RAMP-T system θ setting

RAMP-E system ∆ SP setting

Xxxxx XXXX.X XXX.XX XX.XXX

Events

Time events

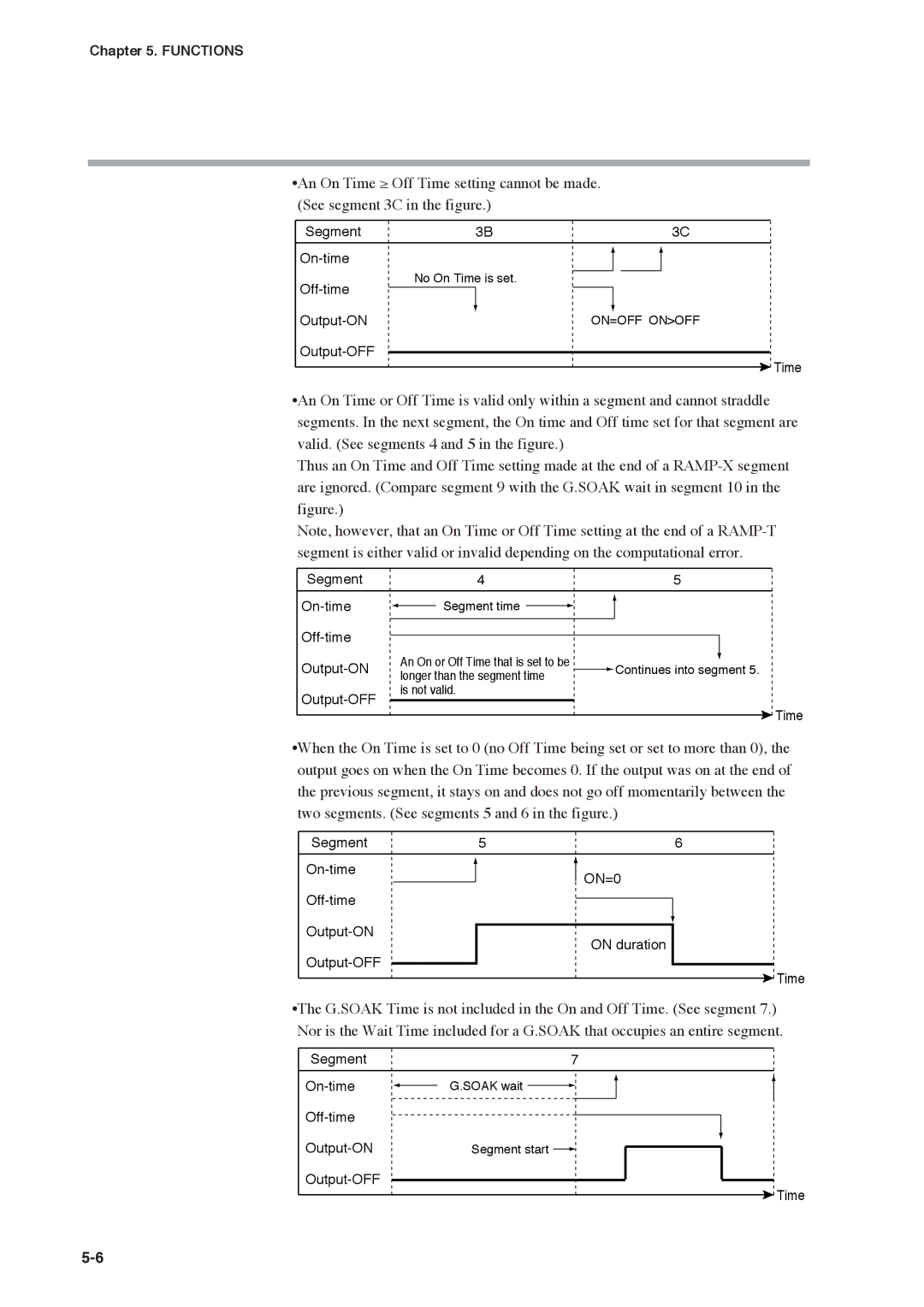

Off-time Output-ON

Output-ON Output-OFF Time

Basic specifications

PV event

Event on delay

SP upper limit SP lower limit MV upper limit MV lower limit

PV deviation rate event

Code event

Example Setting a timed code with 3 output points in event

Functions

Mode event

Basic operations

PID group selection

Selection of ouput limiter group

Soak Guarantee soak

Soak at start of segment

PV shift

Soak at end of segment

Repeat

PV start

Cycle

Pattern link

Tag

Mode types

Mode

Program operation

Constant value control

Hold

Mode transitions

Indicated by the dashed lines in the figure below

Mode transition operations

Operation end

Mode transition restrictions

RUN Hold Reset ADV Fast

Input Process Functions

Model without carbon potential CP compensation

Model with carbon potential CP compensation

PV1

Setting

O2 sensor check model with CP compensation

Objective

Operation

Output Processing Functions

Current output with setup data C21 set to

Control output CH1

PID parameter oL, oH are valid when setup

5G output with setup data C22 set to

Control output CH2

AT not performed during CH2 O2 sensor input

Auxiliary output

Auxiliary output

Power Supply On

Startup flow procedure

##!#

Basic Display Selection

Disp key function When variable parametar PA03 is set to

Program run mode displays

Display A1 Display A2 Display A3

Display A5

Display A4

Display A6

Disp key function when variable parameter PA03 is set to

Display B1 Display B2 Display B3

Display B4

Display B5 Display B6

Handling Precautions

Message key function when variable parameter PA03 is set to

Display D1

Display D2 Display D3 Display D4

Display D5 Display D6

Constant value control mode

Display E1 Display E2 Display E3

Display F1 Display F2 Display F3

Display F4

Selecting Programs

Selecting program numbers

External switch input

External Switch Operation

Types of external switch inputs

Selecting programs

BCD system

###

Binary system

SW1 to 8 and 15 to 16 timing

Read timing

SW9 to 14 and RUN, Fast Ready Fast timing

Auto-tuning AT

Manual Operation and Auto-Tuning

Manual operation

TP-A7 TP-A6 TP-A5 TP-A4 TP-A3 TP-A2 TP-A1

Parameter Setup

Selecting parameter settings groups

Progression of individual items in parameter settings

ConSt when using Func + PID key

Modifying individual items and exiting the setting mode

↑ ↓

Parameter Setting List

Variable parameter setting

$$$$$

=C627

C30*#*6727

C22

Detailed information on variable parameters

PA05 program autoload

OFF

PA31 to PA38 event on delay groups 1 to 4, event/delay time

PA17

$$$$

Settings by event type

++++,%

679

%97

32 #

PID parameter CH1 setting

1rE

CP-A1

CP-A5

PID parameter CH2 setting

#CP %

OL-6 OH-6 1d-7 RE-7 OL-7 OH-7

CP-A6

Setup data setting

C01016

C11##

0000

=111111

?97

367

C100

Detailed descriptions of setup data settings

C63 time display

Remaining segment time Total operation time

C95 voltage output control C96 voltage output control

SSR = I 0 ⋅ Z + V D

Equation

Handing Precautions

C100 PV2 zener barrier adjustment

Constant value control data CH1 setting

Constant value control data CH2 setting

Selecting number of program to operate

Program Setup

Selecting channel of program to operate

Starting programming

State transition

Key operations

Start of display items

Program Setup

5555555555

Programming map

Setting pattern items

Display items

Display

When the event is a PV event

Setting event items Handling Precautions

Display PV events

When the event is a time event

Display time event

When the event is a code event

Display code event

When the event is a timer code event

Display Code event with a timer function

When the event is an event off

When the event is an instrument event

Setting PID groups and output limiter group number items

Setting G.SOAK Guarantee soak items

Setting PV shift items

Setting repeat items

Setting PV start items

Setting cycle items

Setting pattern link items

Setting tag items

↓key ↑key

Deleting programs

Inserting and deleting segments

Display segment insertion Display segment deletion

Program Setup

Program copy procedures

Copying Programs

General Reset

General reset procedures

Memory card types

Memory Card Type and Functions

Memory card functions

Save Procedures

Save menu

Procedures for formatting cards

Procedures for saving single programs

Procedures for saving setup data

Procedures for saving all programs

Procedures for saving variable parameters

Procedures for saving event configuration data

Procedures for saving PID parameters

Procedures for saving all parameters

Load Procedures

Load menu

Card battery alarm panel

Procedures for loading individual programs

Procedures for loading all programs

Procedures for loading setup data

Procedures for loading variable parameters

Procedures for loading PID parameters

Procedures for loading event configuration data

Procedures for loading all parameters

DCP552

DCP552 Mark

Key operated autoload procedure

Autoload

Conditions

Operation and action

Auto load using external switch inputs

Error Message List

Power on self-diagnostic routines

10 1 Self-Diagnostic Functions and Alarm Code Displays

Self-diagnostic routines performed each sampling cycle

Alarm classification

Alarm code display

10-2

10 2 Key Input Related Problems

Normal display mode problems

Fast mode cannot be invoked with Func and → keys

Manual mode cannot be invoked with A/M key

Auto mode cannot be invoked with A/M key

Autotuning AT cannot be started with AT key

Autotuning cannot be canceled with AT key

Setup data setting state cannot be invoked with Setup key

Program copy cannot be performed with ↑ and Prog keys

10-5

Parameter setting related problems

Program setting related problems

Registration state cannot be invoked with Enter key

Event items cannot be displayed with ↑ and ↓ keys

C60

10-7

10 3 When the BAT LED Flashes

Replacing the battery

BAT LED flashes

Items to be provided by the user

Battery replacement procedures

10-9

Troubleshooting

10-10

10-11

53!7

11-1

342

11-2

11-3

11-4

$0+A

11-5

?A!2

11-6

Attachment/auxiliary devices list

11-7

DCP552

11 2 External Dimensions

11-8

Equipment needed

Precautions before calibration

12-1

12 1 Quick Reference Table for Calibration Items

12-2

$! AdJS?

12-3

12-4

Calibration Flowchart 2/3

12-5

Calibration Flowchart 3/3

12-6

Enter calibration mode

12 2 Calibration Procedures

12-7

Key Key test

Function test

12-8

Digital input test

Display test

12-9

Digital output test for event

Digital output test for control output

12-10

Built-in clock adjustment

PV calibration

Input CH No. select

Gain No. select

Writing into Eeprom

PV zero, span

Press Enter key 12-12

12-13

Cold junction sensor calibration

Current output calibration

Key Carbon potential code calibration

Carbon potential code calibration

12-16

Set Up

12-17

12-18

11. Current Outputs

Pattern graph

Variable parameter setting

DCP552 Parameter Work Sheet

Denotes items settable only on models with CP compensation

PA100

PA111

DCP552 Parameter Work Sheet Event configuration data setting

Event type

E12-1

RUN, HOLD, END, Fast

145 to

DCP552 Parameter Work Sheet PID parameter CH1 setting

OL-1

CP-A3

CP-A4

DCP552 Parameter Work Sheet PID parameter CH2 setting

CP-A1

CP-A4

DCP552 Parameter Work Sheet Setup data setting

6D output Voltage time proportional control output system B

19999 to +20000 SPU C45 not equal to

RAMP-E

C100

Fixed command control data CH2 setting

ConSt

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Index

Index-1

PV start

Index-2

Revision History

97-12 EN1I-6187 1st Edition 98-05 2nd Edition

98-11 3rd Edition

00-11 4th Edition

01-12 EN1I-6187 5th Edition

Honeywell Service Centers

Argentina

No. CP-UM-5025E

![]() Time

Time![]() Time

Time![]() Time

Time![]() Time

Time