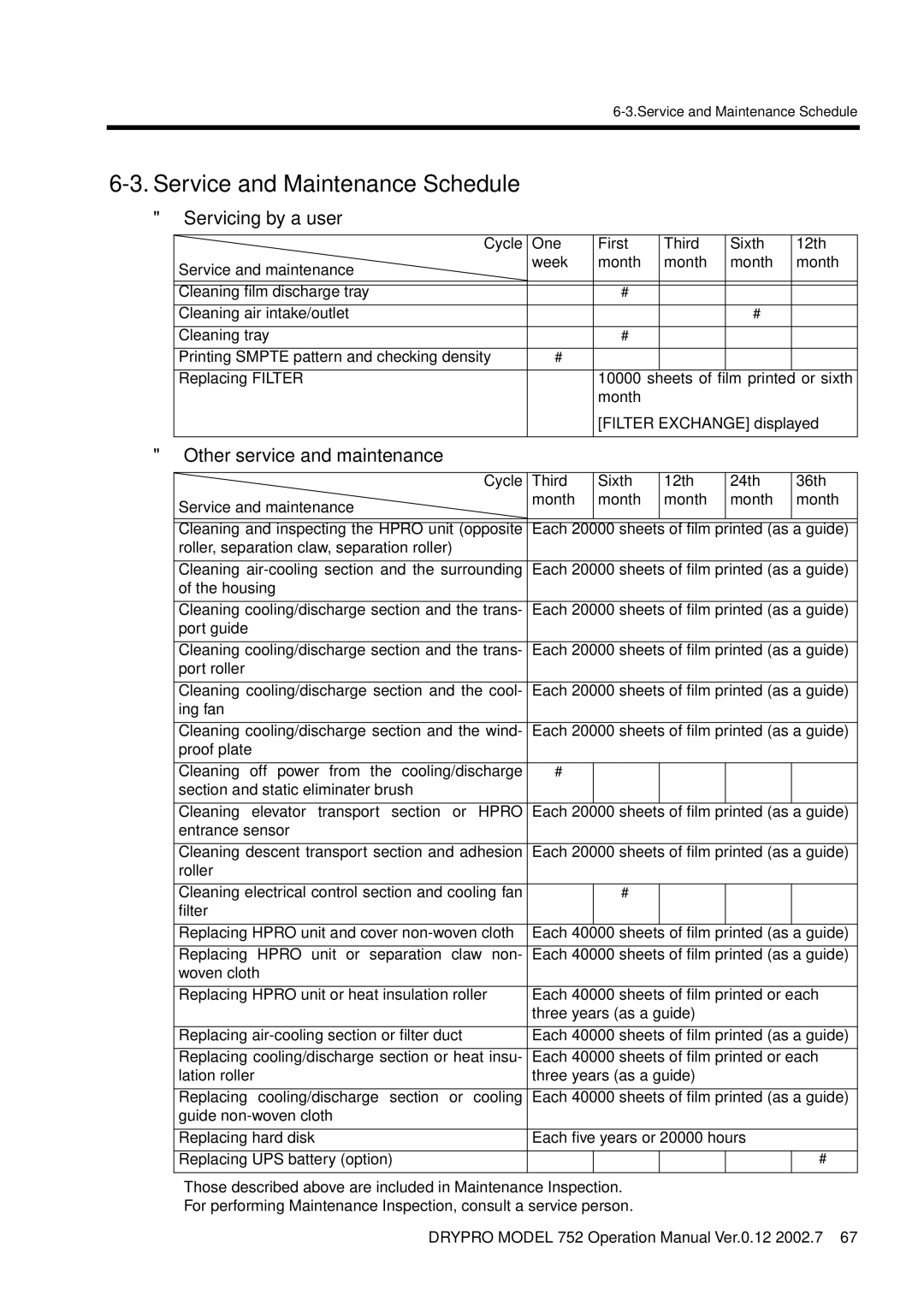

6-3. Service and Maintenance Schedule

" Servicing by a user

Cycle | One | First |

| Third | Sixth | 12th |

|

Service and maintenance | week | month |

| month | month | month |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cleaning film discharge tray |

| # |

|

|

|

|

|

Cleaning air intake/outlet |

|

|

|

| # |

|

|

|

|

|

|

|

|

|

|

Cleaning tray |

| # |

|

|

|

|

|

|

|

|

|

|

|

|

|

Printing SMPTE pattern and checking density | # |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Replacing FILTER |

| 10000 | sheets of film printed or sixth |

| |||

|

| month |

|

|

|

|

|

|

| [FILTER EXCHANGE] displayed |

| ||||

|

|

|

|

|

|

|

|

" Other service and maintenance

Cycle | Third | Sixth | 12th | 24th | 36th |

Service and maintenance | month | month | month | month | month |

|

|

|

|

| |

Cleaning and inspecting the HPRO unit (opposite | Each 20000 sheets of film printed (as a guide) | ||||

roller, separation claw, separation roller) |

|

|

|

|

|

Cleaning | Each 20000 sheets of film printed (as a guide) | ||||

of the housing |

|

|

|

|

|

Cleaning cooling/discharge section and the trans- | Each 20000 sheets of film printed (as a guide) | ||||

port guide |

|

|

|

|

|

Cleaning cooling/discharge section and the trans- | Each 20000 sheets of film printed (as a guide) | ||||

port roller |

|

|

|

|

|

Cleaning cooling/discharge section and the cool- | Each 20000 sheets of film printed (as a guide) | ||||

ing fan |

|

|

|

|

|

Cleaning cooling/discharge section and the wind- | Each 20000 sheets of film printed (as a guide) | ||||

proof plate |

|

|

|

|

|

Cleaning off power from the cooling/discharge | # |

|

|

|

|

section and static eliminater brush |

|

|

|

|

|

Cleaning elevator transport section or HPRO | Each 20000 sheets of film printed (as a guide) | ||||

entrance sensor |

|

|

|

|

|

Cleaning descent transport section and adhesion | Each 20000 sheets of film printed (as a guide) | ||||

roller |

|

|

|

|

|

Cleaning electrical control section and cooling fan |

| # |

|

|

|

filter |

|

|

|

|

|

Replacing HPRO unit and cover | Each 40000 sheets of film printed (as a guide) | ||||

Replacing HPRO unit or separation claw non- | Each 40000 sheets of film printed (as a guide) | ||||

woven cloth |

|

|

|

|

|

Replacing HPRO unit or heat insulation roller | Each 40000 sheets of film printed or each | ||||

| three years (as a guide) |

|

| ||

Replacing | Each 40000 sheets of film printed (as a guide) | ||||

Replacing cooling/discharge section or heat insu- | Each 40000 sheets of film printed or each | ||||

lation roller | three years (as a guide) |

|

| ||

Replacing cooling/discharge section or cooling | Each 40000 sheets of film printed (as a guide) | ||||

guide |

|

|

|

|

|

Replacing hard disk | Each five years or 20000 hours |

| |||

Replacing UPS battery (option) |

|

|

|

| # |

Those described above are included in Maintenance Inspection.

For performing Maintenance Inspection, consult a service person.

DRYPRO MODEL 752 Operation Manual Ver.0.12 2002.7 67