Maintenance

12.10 Paradenser—Water-Cooled Condenser

During normal Paradenser operation, deposits will collect on inside wall of condenser tubes. It must be cleaned periodically to ensure proper operation. Frequency of cleaning must be locally established because it varies according to Paradenser usage and local fluid quality. See 12.9 - Facility Fluid and Piping Maintenance.

12.10.1 Cleaning Instructions

Refer to Figure 1 - Downflow model component locations.

1.Disconnect power to unit.

2.Close

3.Remove access panel from front of compressor section.

4.Locate the 1/2" NPT drain plugs located at lower front of compressor section and provide means to collect fluid drained from system

5.Remove the 1/2" drain plugs using two wrenches to prevent damage to drain lines.

6.Locate and remove the 3" diameter clean out plugs on top of shell assemblies (use Craftsman™

7.Brush and flush each of the nominal 5/8" inner diameter, rifled copper tubes. Recommend using John R. Robinson, Inc. or similar:

•Motorized Tube Cleaner, Model

•Nylon brush 9/16" diameter, Model

•Flexible shaft, Model

8.Reinstall 1/2" drain plugs 6 to 7 turns using Loctite 567 PST Thread Sealant as instructed by the manufacturer.

9.Wipe clean the machine threads and sealing surfaces of 3" diameter clean out plugs.

10.Remove and install new

11.Hand tighten 3" diameter clean out plugs and torque using drag link socket to 25

12.Leak check fluid system (refer to Leak Checking of Unit and Field Piping on page 75).

13.Bleed system using Schrader ports near the top of the Paradenser.

14.Ensure that condensing fluid isolation valves are fully open.

15.Unit is ready to be put

12.11 Water/Glycol Control Valves

12.11.1Regulating Valves – Semi Hermetic and Standard Scroll Compressors

The water regulating valves automatically regulate the amount of fluid necessary to remove the heat from the refrigeration system, permitting more water to flow when load conditions are high and less fluid to flow when load conditions are low. The valve consists of a brass body, balance spring, valve seat, valve disc holders, capillary tube to discharge pressure, and adjusting screw.

Adjustment—Johnson Controls/Penn Johnson Valves

The valves may be adjusted with a standard refrigeration service valve wrench or screwdriver.

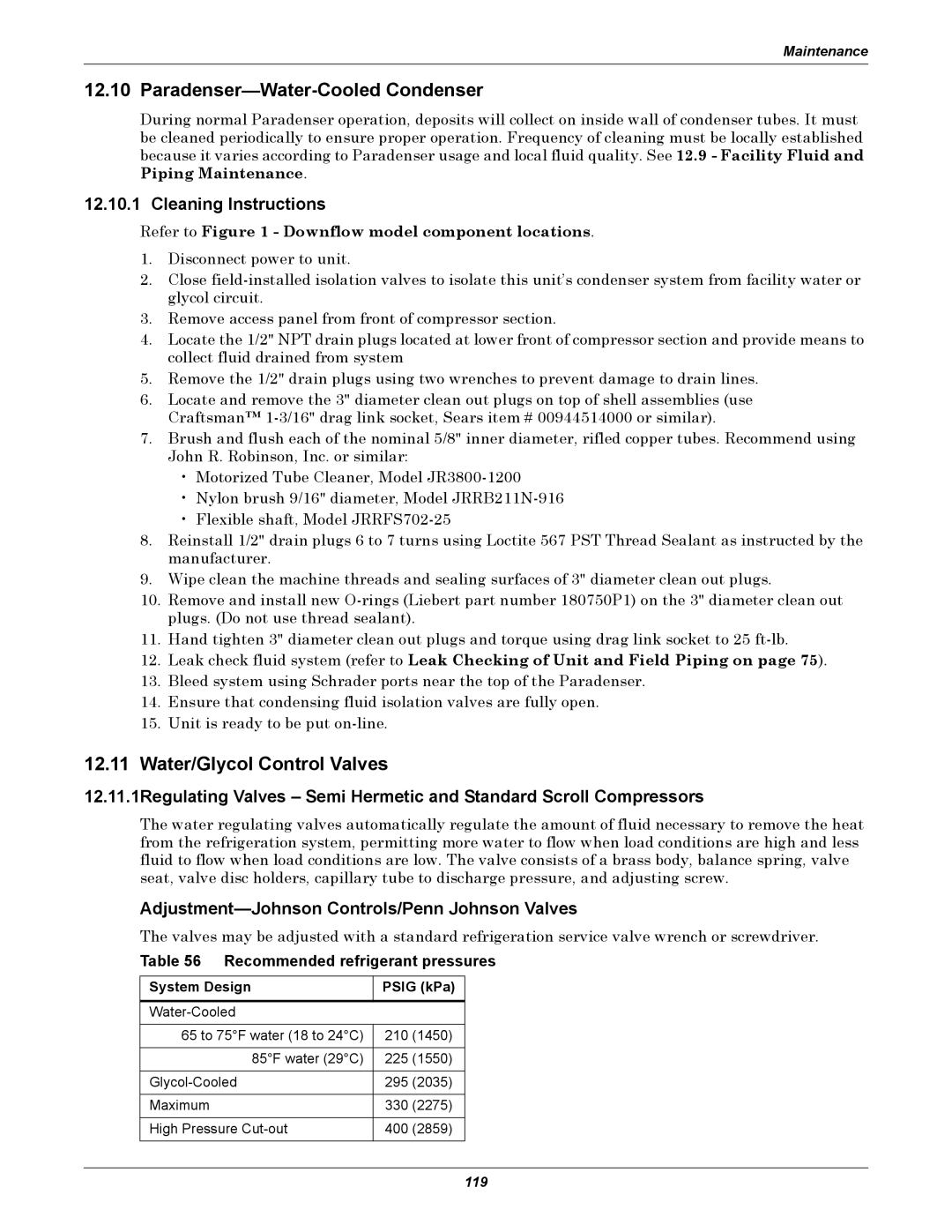

Table 56 Recommended refrigerant pressures

System Design

PSIG (kPa)

65 to 75°F water (18 to 24°C) | 210 (1450) |

|

|

85°F water (29°C) | 225 (1550) |

|

|

295 (2035) | |

|

|

Maximum | 330 (2275) |

|

|

High Pressure | 400 (2859) |

|

|

119