Liebert DS

Page

Table of Contents

Electrical Connections

Maintenance

Piping

108

Compressor Replacement

Hvac Maintenance Checklist

Figures

Page

Page

Tables

Viii

Important Safety Instructions

Page

Downflow model component locations

Liebert DS Components and Nomenclature

Upflow model component locations

= Dual-Cooling Water/Glycol Three-stage Compressor

U a

Glycool

Cooling Configurations

PRE-INSTALLATION Guidelines

Room Preparation

Air Distribution-Downflow Units

Air Distribution-Upflow Units

Upflow ducting configurations

Operating Conditions

Connections and System Setup

Shipping dimensions-domestic and export, inches mm

Liebert DS Dimensions and Weights

Shipping weights-approximate, kg

028/035/042 053/070/077

Model No 028, 035

Approximate

Dry Weight, lb kg Approximate Model No 028, 035

Top View

Front View

DPN000894

Dry Weight lb. kg Approximate

51mm

GLYCOOL/Dual-Cool

Front View

Dry Weight, lb kg Approximate Model 053 070 077

070 077

Dry Weight, lb kg Approximate Model No

TOP View

Compressor Dry Weight, lb kg, Approximate Type Model 053

Dry Weight, lb kg approximate Compressor Type Model

Top View

Front View

Dry Weight, lb kg approximate Compressor Type Model 105

Dry Weight, lb kg

Model No 028-042

Compressor Type Model

Dry Weight, lb kg approximate

Alternate Refrigerant Piping Entrance

Model No 053, 070

Top View

Weights-upflow, air-cooled, 105kW 30 ton, all

Dry Weight, Approximate, lb kg

Model 105

Compressor GLYCOOL/Dual-Cool

Height, in. mm Turning Vane

Dimensions, in. mm Model

Floor stand dimensions-downflow, 53-77kW 15-22 ton models

Floor stand dimensions-downflow, 105kW 30 ton models

Models Blower Supply

Dimensions for upflow, 28-42kW 8-12 ton

Dimensions, in. mm Models Blower Supply

Blower outlet and deck dimensions-upflow, 53-77kW 15-22 ton

Dimensions, in. mm Models Blower

Blower outlet and deck dimensions-upflow 105kW 30ton

Dimensions, in mm Compressor Type # Filters

Rear return filter box dimensions

Left Side Views Right Side Views Check One

Equipment Inspection and Handling

Packaging Material

Step 181659P1 Rev

Unpacking the Unit

Step

Removing the Unit from the Skid With a Forklift

Removing Piano Jacks

Moving the unit to its installation location

Rev

Removing Liebert DS from Skid Using Rigging

Lifting Sling Equal Equal Distance Distance

Placing the Unit on a Floor Stand

Semi-Hermetic Compressor Spring Isolation System

Detail a

Liebert Floor Stand front discharge shown

Disassembly-Downflow Units

Required Equipment

Disassembling the Liebert DS for Transport

Reheat-Optional Component

Remove the Filter and Electric Box Assembly

Remove the Compressor Assembly

Reconnecting Piping, Charging and Replacing Panels

Reassembly-Downflow Units

Reassembly Checklist

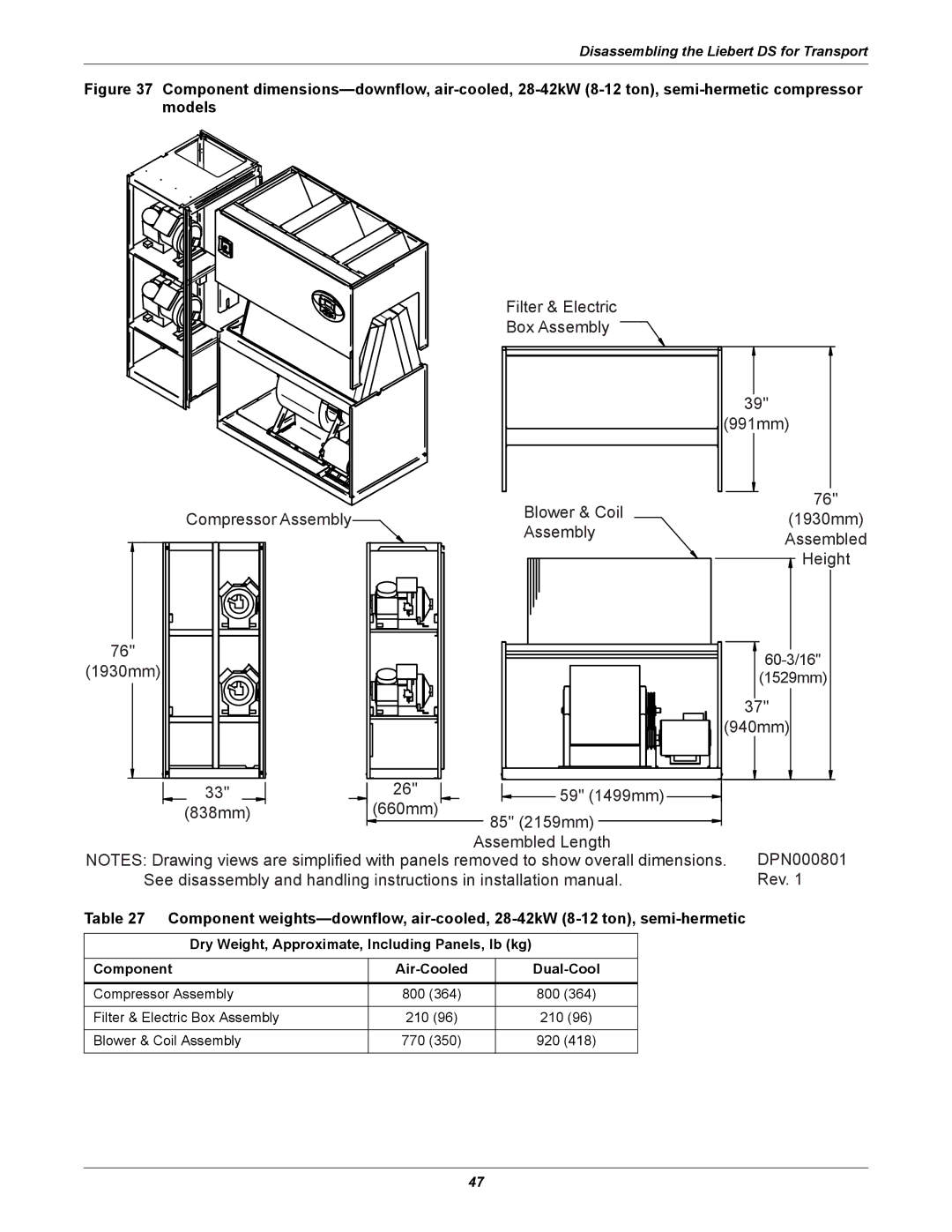

Filter & Electric Box Assembly

Filter & Electric Box Assembly

940mm

1930mm

Assembly Assembled Height 1930mm 59-7/16

Filter and Electric Box Assembly

Blower & Coil Assembly

Semi-Hermetic Compressor Scroll Compressor

Component Air Cooled Dual Cool

Dry Weight, lb kg Approximate Includes Panels

Filter & Electric

1510mm

Disassembly-Upflow Units

Remove Blower and Electric Box Assembly

Remove Compressor Assembly

Reassembly-Upflow Unit

2159mm

31-1/4 794mm

85 2159mm Assembled Length

660mm 2083mm 108 2743mm Assembled Length

82 2083mm

Blower & Electric Box Assembly 31-1/4

REV

REV

31-1/4 794mm

Electrical Connections

Downflow LOW Volt Section

Electrical Field Connection Descriptions

Standard Electrical Connections

Optional Electrical Connections

Optional Low Voltage Terminal Package Connections

Fluid Connections

Condensate Piping-Field-Installed

Piping

Gravity Drain

Gravity drain for downflow and upflow units

Condensate Pump

Requirements of Systems Using Water or Glycol

Humidifier Supply Water-Optional Infrared

General Guidelines

Leak Checking of Unit and Field Piping

Refrigeration Piping

Recommended refrigerant line sizes OD copper inches

Piping Guidelines-Air-Cooled Units

Fan Lee-Temp Model Speed Includes receiver

Liquid Line, lb kg

Fan Speed Control Leak Check and Evacuation Procedure

Fan Speed Control Piping

Fan Speed Control Materials Supplied

Fan Speed Charging

Fan speed suction pressure transducer settings

Lee-Temp Leak Check and Evacuation Procedure

Lee-Temp Piping

Lee-Temp Controlled Materials Supplied

Lee-Temp suction pressure transducer settings

Lee-Temp Charging

Lee-Temp Receiver Refrigerant Level

Piping schematic-air-cooled, semi-hermetic compressor models

Piping Schematics

Fan Speed

Lee-Temp

Liebert DS Unit

Customer Heat Rejection

Liebert

Associated piping

Piping schematic-GLYCOOL semi-hermetic compressor models

Liebert

Customer Heat Rejection

Glycool with digital scroll compressor models

DPN000805 Rev

Optional piping schematic for Econ-O-Coil

Point Description Inches mm

Connection Size / Opening

DPN000804

Front of Unit

53kW 15ton / 70 & 77kW 20 & 22ton

DPN000929 Rev

DPN000933

HUM E1 E2 Front of Unit

DPN001015

CGD

TOP View

Top View of Unit

Left Side Section View

Front Section View

Point Description In. mm

53kW 15 ton/70 & 77kW 20 & 22 ton

Left Side Section View of Unit

53kW 15 tons/70 & 77kW 20 & 22 ton

Left Side Section View

Front Section View

Left Side Section View

Point Description Connection Size / Opening

Piping data-upflow, air-cooled 105kW 30 ton, all

Point Description Inches mm Opening, inches mm

Connection Size

Moving and Placing Equipment

Checklist for Completed Installation

Electrical

Other

108

109

Commissioning Procedure With Panels On

Filters

Maintenance

Filter quantities, downflow units

Filter quantities, upflow units

Filter Replacement Procedure-Downflow Units

Filter Replacement Procedure-Upflow Units

Blower Drive System

Upflow Motor Access

Belt Installation and Tensioning

Belt Removal

Blower Bearing Replacement

Blower Bearing Maintenance

Blower Bearing Inspection

Blower Motor

Humidifier

Correct orientation of float switch

Changing Humidifier Lamps

Condensate Drain and Condensate Pump Systems

Condensate Drain

Infrared Bulbs

Air-Cooled Condenser and Drycoolers

Reheat-Electric Reheat Three-Stage and SCR

Compressor

Facility Fluid and Piping Maintenance

Compressor Replacement

Adjustment-Johnson Controls/Penn Johnson Valves

Cleaning Instructions

Paradenser-Water-Cooled Condenser

Water/Glycol Control Valves

Adjustment

Testing Function of Valve

Location

12.11.2Motor Ball Valve-Digital Scroll Compressors

Aquastat settings-two-fan through four-fan drycoolers

12.11.3Drycooler Settings

Aquastat settings-six-fan drycoolers

Aquastat settings-eight-fan drycoolers

Hvac Maintenance Checklist

Water-Cooled Condensers

Refrigeration Piping

Compressor Section

Electrical Panel

Glycol Pump

Air-Cooled Condenser / Drycooler

Page

Iti

Ne t

Ti n

That

![]() Height

Height