Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

|

| OPERATION | |||||

CONTROLS AND SETTINGS |

| ||||||

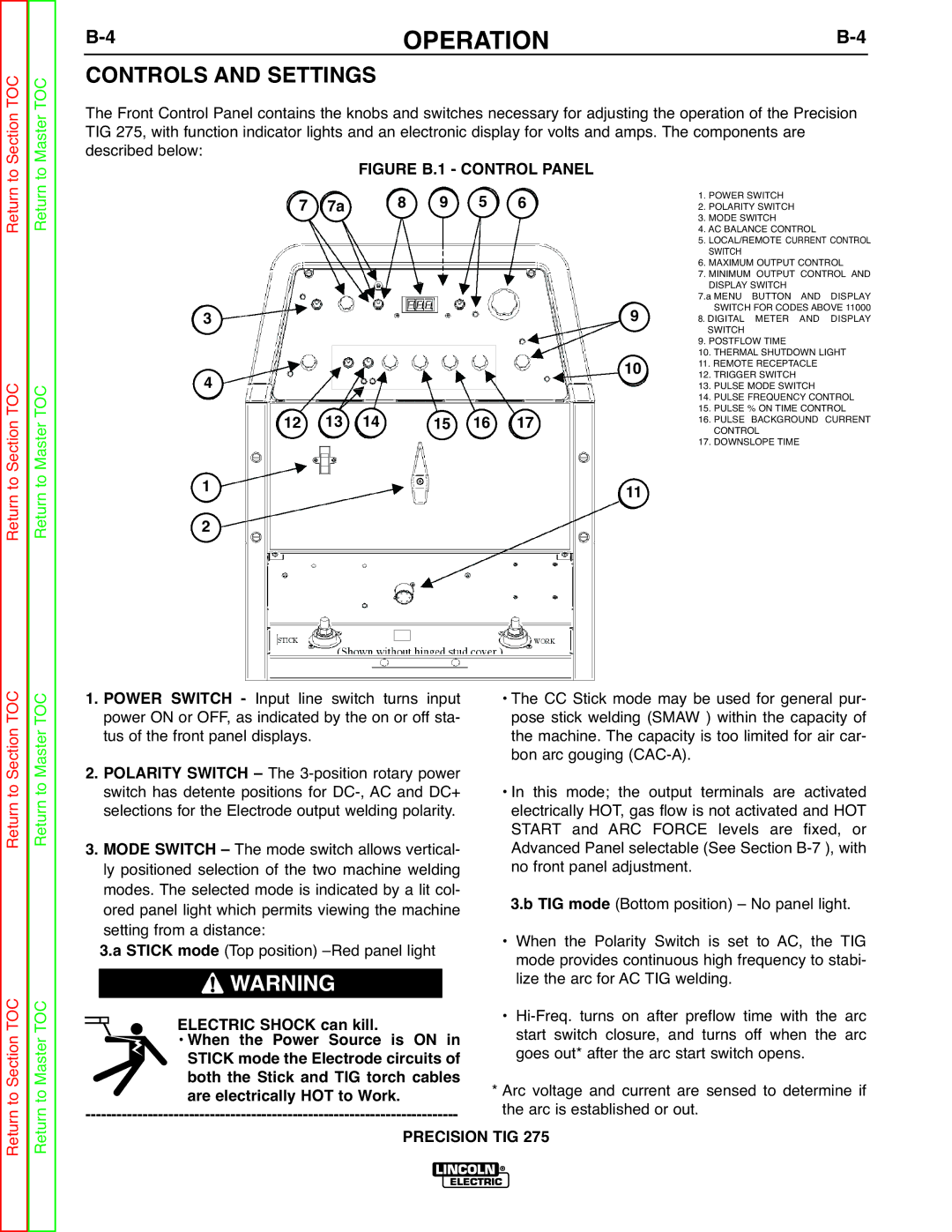

The Front Control Panel contains the knobs and switches necessary for adjusting the operation of the Precision | |||||||

TIG 275, with function indicator lights and an electronic display for volts and amps. The components are | |||||||

described below: |

| FIGURE B.1 - CONTROL PANEL |

| ||||

7 | 7a |

| 8 | 9 | 5 | 6 | 1. POWER SWITCH |

| 2. POLARITY SWITCH | ||||||

|

|

|

|

| 3. MODE SWITCH | ||

|

|

|

|

|

|

| 4. AC BALANCE CONTROL |

|

|

|

|

|

|

| 5. LOCAL/REMOTE CURRENT CONTROL |

|

|

|

|

|

|

| SWITCH |

|

|

|

|

|

|

| 6. MAXIMUM OUTPUT CONTROL |

|

|

|

|

|

|

| 7. MINIMUM OUTPUT CONTROL AND |

|

|

|

|

|

|

| DISPLAY SWITCH |

3 |

|

|

|

|

| 9 | 7.a MENU BUTTON AND DISPLAY |

|

|

|

|

| SWITCH FOR CODES ABOVE 11000 | ||

|

|

|

|

| 8. DIGITAL METER AND DISPLAY | ||

|

|

|

|

|

| SWITCH | |

|

|

|

|

|

|

| 9. POSTFLOW TIME |

|

|

|

|

|

| 10 | 10. THERMAL SHUTDOWN LIGHT |

4 |

|

|

|

|

| 11. REMOTE RECEPTACLE | |

|

|

|

|

| 12. TRIGGER SWITCH | ||

|

|

|

|

|

| 13. PULSE MODE SWITCH | |

12 | 13 | 14 |

| 15 | 16 | 17 | 14. PULSE FREQUENCY CONTROL |

| CONTROL | ||||||

|

|

|

|

|

|

| 15. PULSE % ON TIME CONTROL |

|

|

|

|

|

|

| 16. PULSE BACKGROUND CURRENT |

1 |

|

|

|

|

|

| 17. DOWNSLOPE TIME |

|

|

|

|

| 11 |

| |

2 |

|

|

|

|

|

|

|

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

1. POWER SWITCH - Input line switch turns input | • The CC Stick mode may be used for general pur- | |

| power ON or OFF, as indicated by the on or off sta- | pose stick welding (SMAW ) within the capacity of |

2. | tus of the front panel displays. | the machine. The capacity is too limited for air car- |

POLARITY SWITCH – The | bon arc gouging | |

| switch has detente positions for | • In this mode; the output terminals are activated |

| selections for the Electrode output welding polarity. | electrically HOT, gas flow is not activated and HOT |

3. MODE SWITCH – The mode switch allows vertical- | START and ARC FORCE levels are fixed, or | |

Advanced Panel selectable (See Section | ||

| ly positioned selection of the two machine welding | no front panel adjustment. |

| modes. The selected mode is indicated by a lit col- | 3.b TIG mode (Bottom position) – No panel light. |

| ored panel light which permits viewing the machine | |

| setting from a distance: | • When the Polarity Switch is set to AC, the TIG |

| 3.a STICK mode (Top position) | mode provides continuous high frequency to stabi- |

| WARNING | lize the arc for AC TIG welding. |

| ELECTRIC SHOCK can kill. | • |

| • When the Power Source is ON in | start switch closure, and turns off when the arc |

| STICK mode the Electrode circuits of | goes out* after the arc start switch opens. |

| both the Stick and TIG torch cables | * Arc voltage and current are sensed to determine if |

| are electrically HOT to Work. | |

the arc is established or out. | ||

| PRECISION TIG 275 | |