TOC TOC

THEORY OF OPERATION |

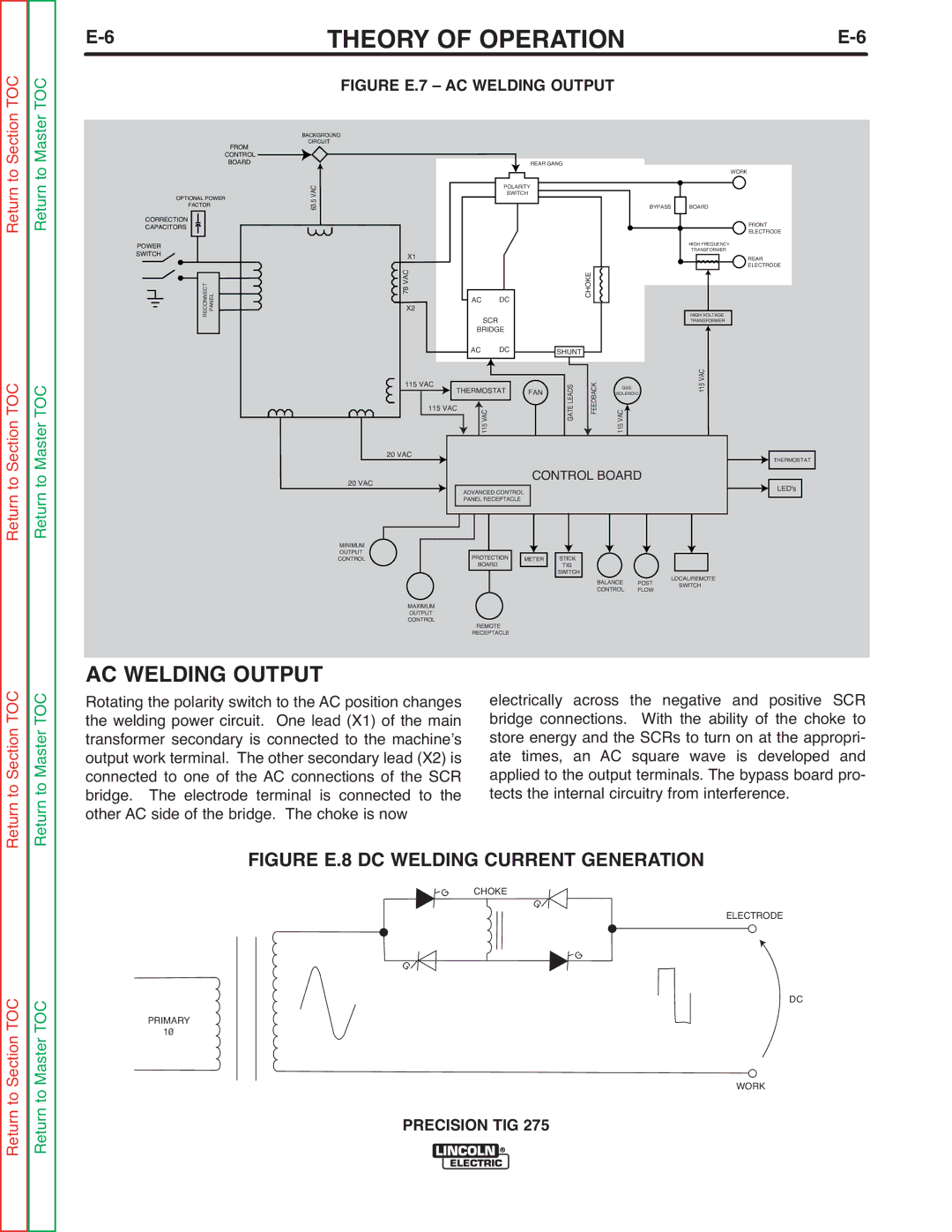

FIGURE E.7 – AC WELDING OUTPUT

Return to Section Return to Master

FROM

CONTROL

BOARD

OPTIONAL POWER

CORRECTIONFACTOR

CAPACITORS

POWER

SWITCH

PANEL

RECONNECT

BACKGROUND

CIRCUIT

63.5 VAC

|

|

| REAR GANG |

| WORK |

|

| POLARITY |

|

| |

|

|

|

|

| |

|

| SWITCH | BYPASS | BOARD |

|

|

|

| FRONT | ||

|

|

|

|

| |

|

|

|

| HIGH FREQUENCY | ELECTRODE |

X1 |

|

|

|

| |

|

|

| TRANSFORMER | REAR | |

78 VAC |

|

| CHOKE |

| ELECTRODE |

AC | DC |

|

| ||

X2 |

|

|

| ||

SCR |

|

| HIGH VOLTAGE |

| |

|

|

| TRANSFORMER |

| |

| BRIDGE |

|

|

| |

| AC | DC | SHUNT |

|

|

Return to Section TOC Return to Master TOC

115 VAC THERMOSTAT

115 VAC ![]()

![]() VAC115

VAC115

20 VAC

20 VAC

LEADSGATE | FEEDBACK | GAS |

VAC | ||

FAN |

| SOLENOID |

|

| 115 |

CONTROL BOARD

115 VAC

THERMOSTAT

LED's

Return to Section TOC Return to Master TOC

MINIMUM |

|

|

|

|

|

|

OUTPUT | PROTECTION | METER | STICK |

|

|

|

CONTROL |

|

|

| |||

| BOARD |

| TIG |

|

|

|

|

|

| SWITCH | BALANCE | POST | LOCAL/REMOTE |

|

|

|

| CONTROL | FLOW | SWITCH |

MAXIMUM

OUTPUT

CONTROL

AC WELDING OUTPUT

Rotating the polarity switch to the AC position changes the welding power circuit. One lead (X1) of the main transformer secondary is connected to the machineʼs output work terminal. The other secondary lead (X2) is connected to one of the AC connections of the SCR bridge. The electrode terminal is connected to the other AC side of the bridge. The choke is now

FIGURE E.8 DC WELDING CURRENT GENERATION

G | CHOKE | G | ELECTRODE |

|

| ||

|

|

| |

G |

|

| G |

|

|

|

Section TOC Master TOC

PRIMARY 10

DC

Return to Return to

WORK

PRECISION TIG 275